Cement particle size distribution prediction method based on random distribution

A particle size distribution and prediction method technology, applied in the direction of measuring devices, particle size analysis, particle and settlement analysis, etc., can solve the problem of low prediction accuracy, inability to fully reflect the actual quality and performance of cement, and non-Gaussian characteristics of cement particle size distribution. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

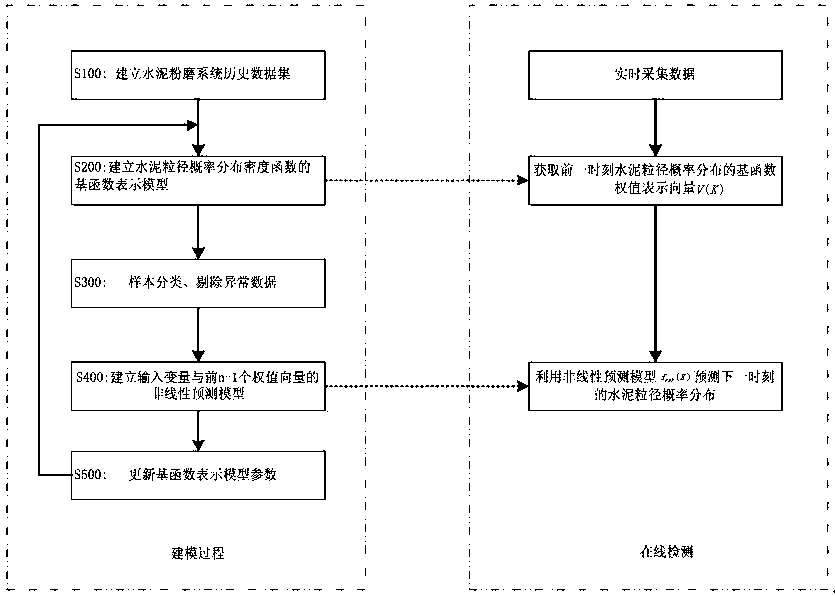

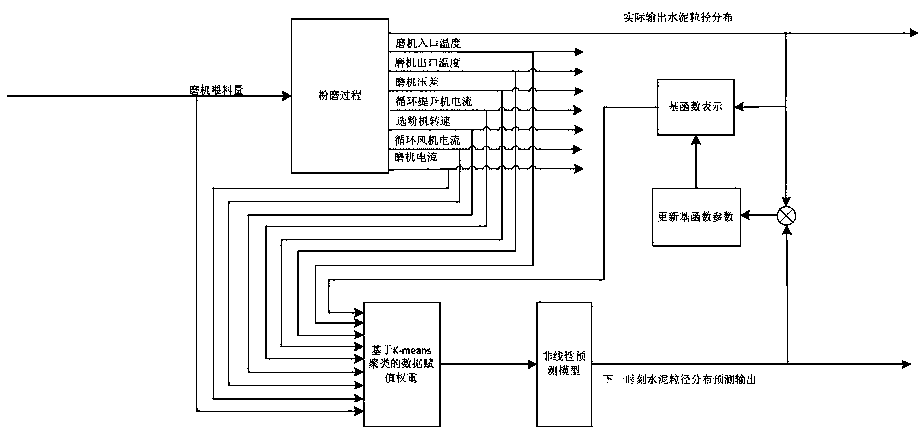

[0076] The cement grinding quality monitoring based on the random distribution prediction algorithm can be implemented by using the modeling process and real-time process:

[0077] The modeling process includes the following steps:

[0078] S100: Store all parameter signals as historical data sets, and the establishment of historical data sets can be implemented in the following ways:

[0079] Historical data needs to collect mill feeding amount, mill current, mill inlet temperature, mill outlet temperature, mill pressure difference, circulating elevator current, powder separator speed, and circulating fan current. Before feeding, put the material on the weighing table for weighing to obtain the feeding amount of the mill, and select the feeding amount of group P fixedly. Install current transformers to record the working current of the mill, circulation hoist, and circulation fan equipment, and install temperature sensors at the 3 / 1 inlet and 3 / 1 outlet of the mill to record...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com