A method for determining the laying form of a pulsed fiber sand fracturing propping agent group

A sand fracturing and proppant technology, which is applied in the field of oil and gas field exploration and development, can solve the problems of complex flow rules and the inability to describe the shape of proppant clusters quantitatively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

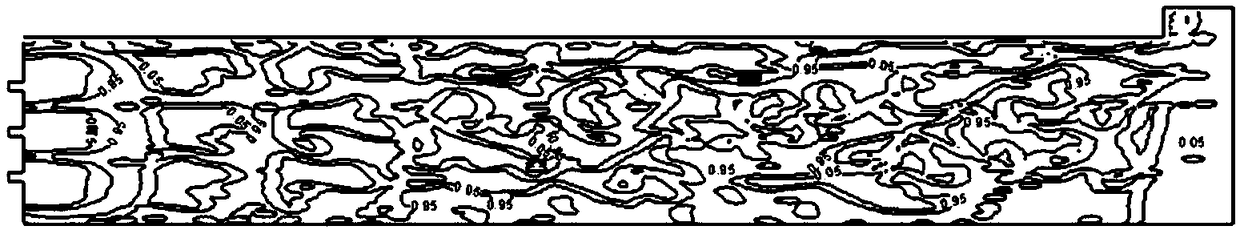

[0058] The physical model of a large-scale flat fracture that simulates proppant transport in the laboratory is used as the research object (Guo Jianchun et al. Experimental study on factors affecting flow channel shape in channel fracturing[J]. Oil and Gas Geology and Recovery, 2017, 24(5: ): 115-119), the crack height of the plate is 0.6m, the crack length is 4.0m, and the crack width is 0.006m. The inlet at the left end of the plate enters liquid through three evenly distributed perforation holes (fluid direction is from left to right), and an outlet is arranged on the top of the right end to discharge liquid. Here, the method of the present invention is implemented with the flat plate fracture as an object to obtain the laying characteristics of the proppant group in the fracture.

[0059] According to the crack size of the flat plate, it is established in the CFD pre-processing software Gambit as follows: figure 1 In the geometric model shown, the three small rectangles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com