OLED display device evaporation method, OLED display device and evaporation equipment

A display device and evaporation technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of low yield and high cost of OLED display devices, achieve small production tact, reduce waiting time, enhance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

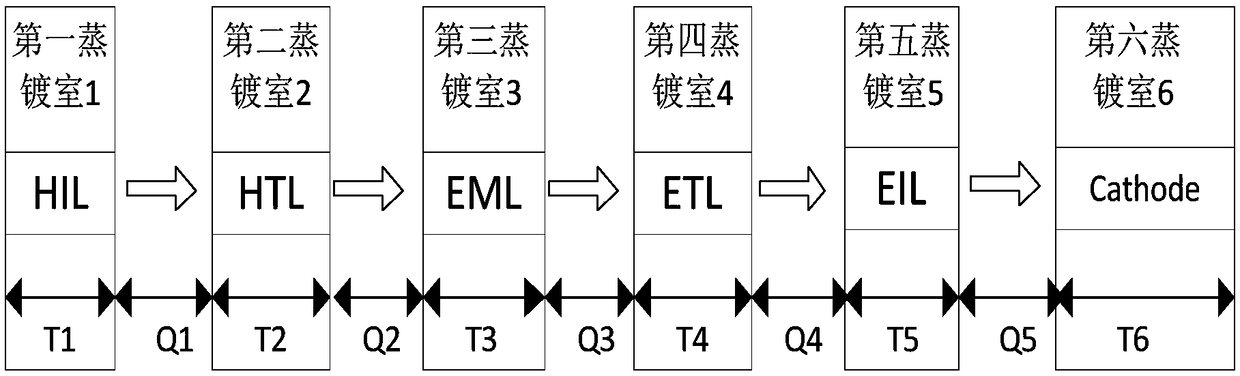

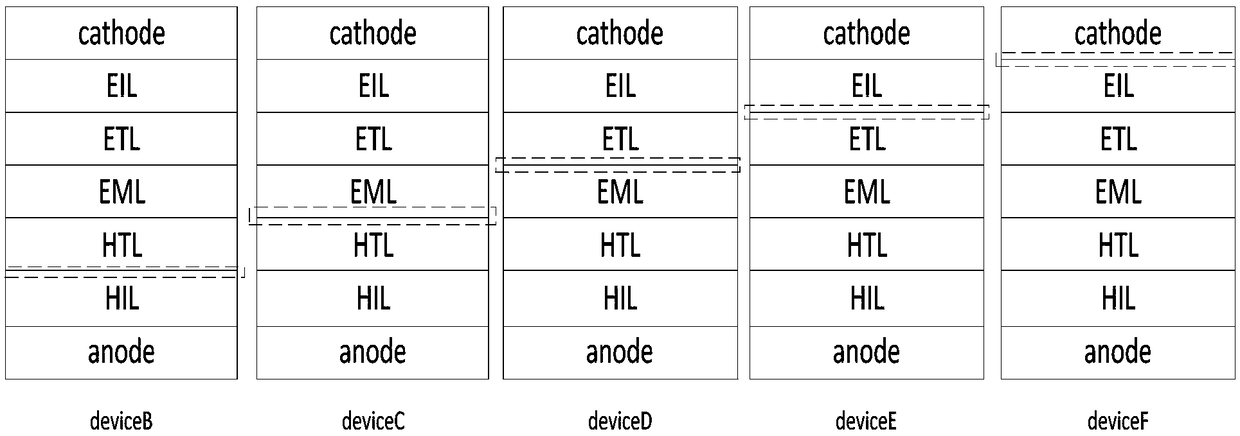

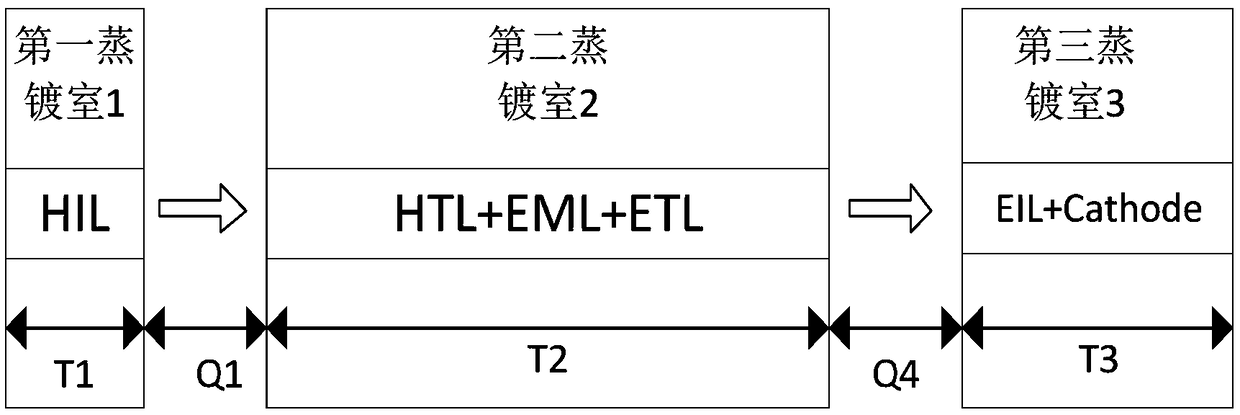

[0038] At least two adjacent layers of HIL, HTL, EML, ETL, ELI, and Cathode can be evaporated in the same evaporation chamber, and the evaporation method of other functional layers is the same as the prior art.

[0039] In order to achieve a better control effect on the yield rate and ensure a higher production capacity, based on the above experiments, the functional layers that have a more critical impact on the yield rate are combined and evaporated. Specifically, the HTL, EML, and ETL can be combined Any two are evaporated in the same evaporation chamber, and the evaporation method of other functional layers is the same as that of the prior art. It is also possible to vapor-deposit only EIL and Cathode in the same evaporation chamber, and the evaporation method of other functional layers is the same as that of the prior art. It should be noted that the evaporation method in the embodiment of the present invention is not limited to the above-mentioned evaporation method. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com