Bolt sleeve electric wire clip

A technology of conductive clips and sleeves, applied in conductive connections, circuits, electrical components, etc., can solve problems such as cable restrictions, consumables, and easy damage to screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

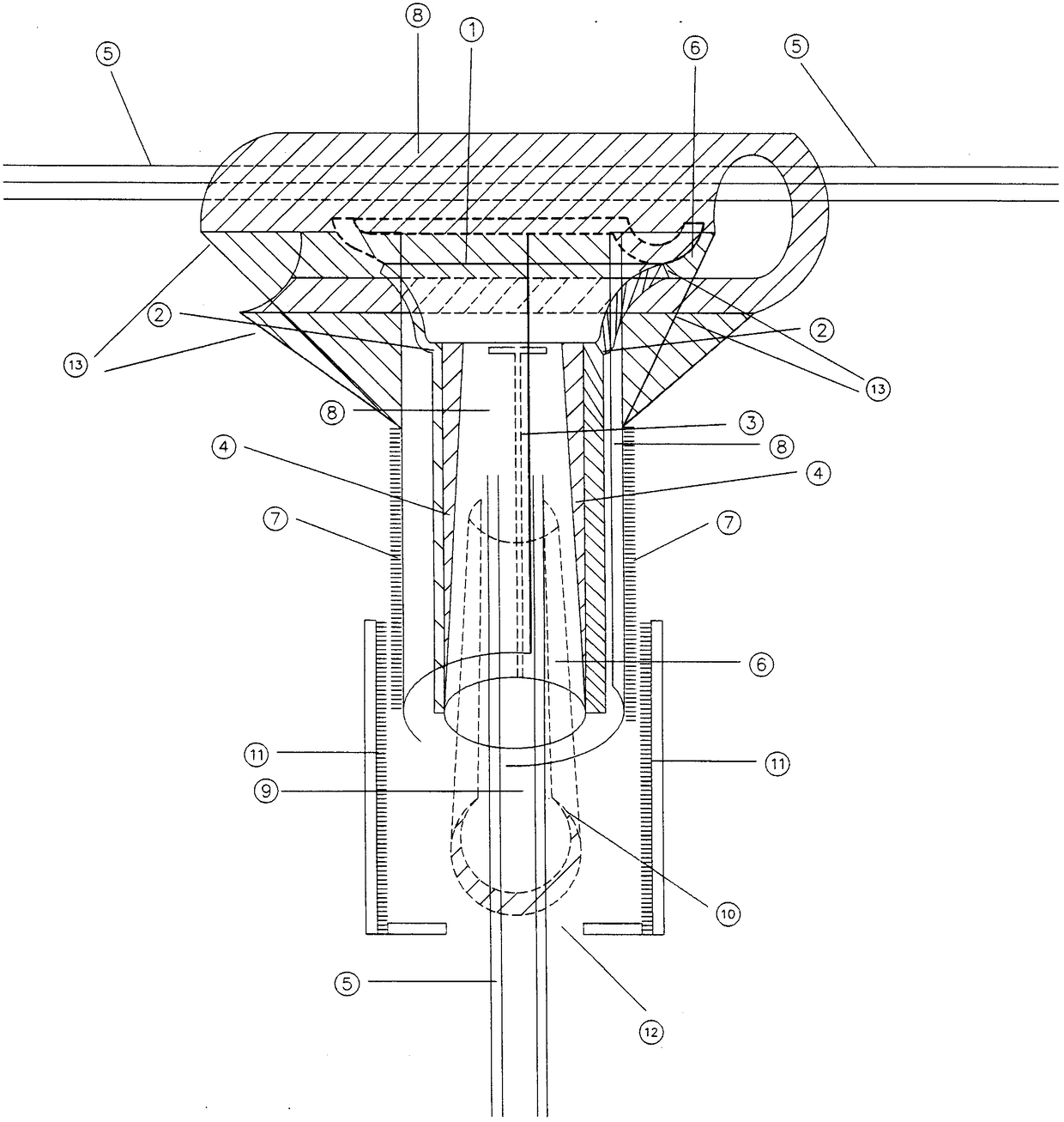

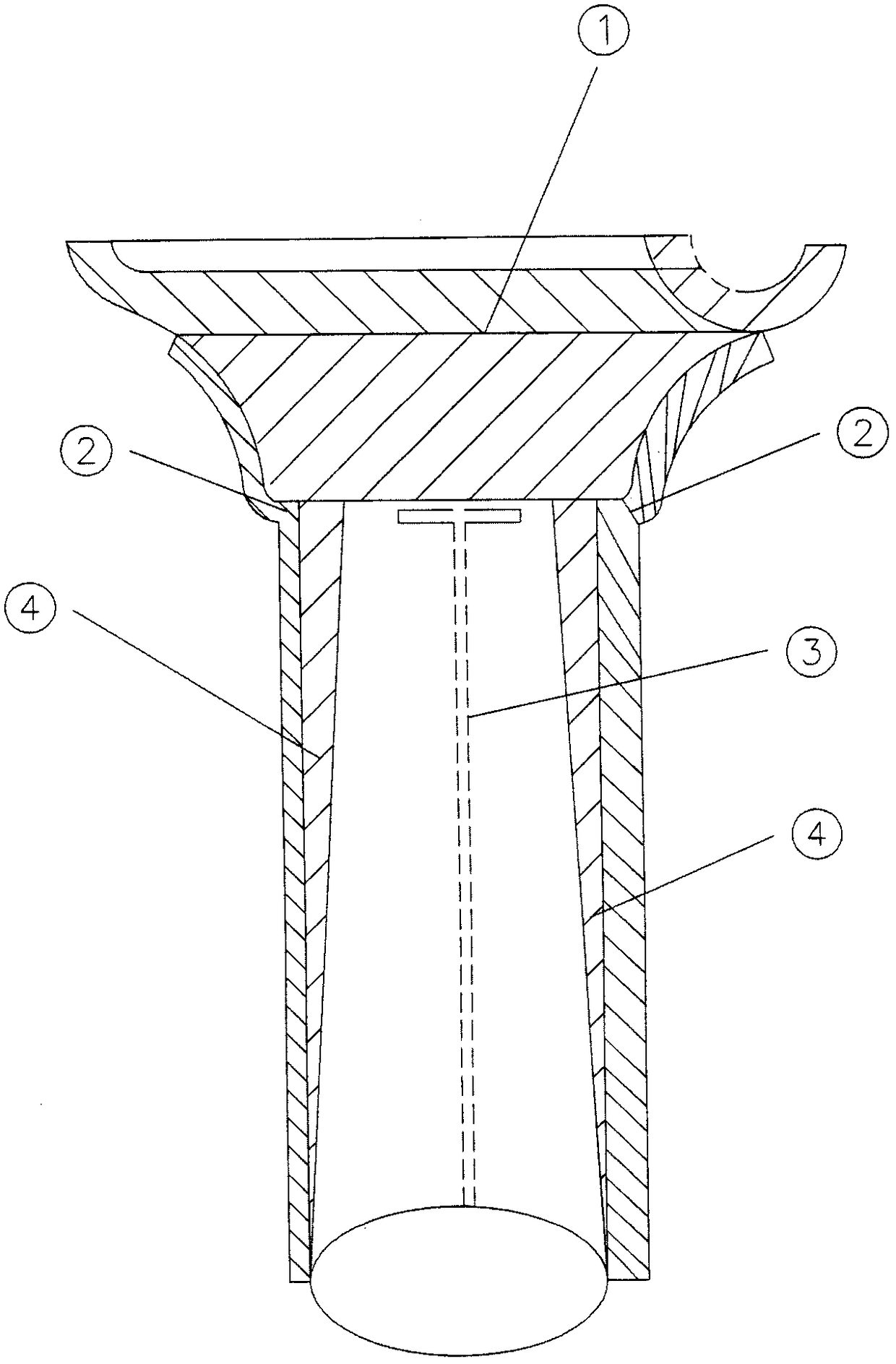

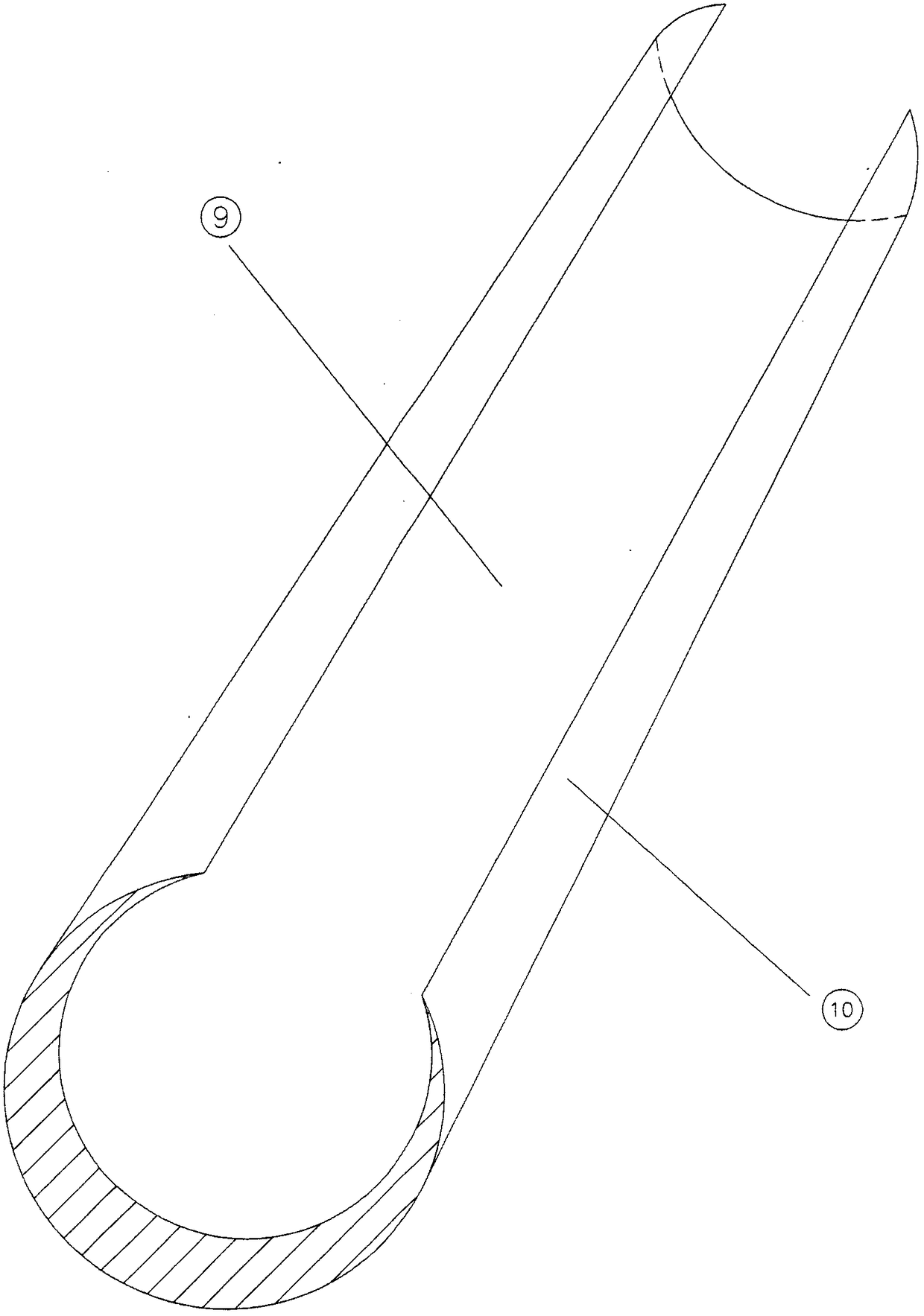

[0007] The conductive wire clamp of the bolt sleeve includes a clamping part, which is characterized in that: the clamping part is. The clamping part of the bolt casing conductive wire clamp of the present invention is a conical shrink sleeve 10 provided with an axial shrinkage groove 9. Body entity triangular brace 13, three-way open sleeve pipe 8 is provided with the wire core that allows halfway peeling can be directly inserted into the inner circle end top of three-way open sleeve pipe 8 for the T-shaped structure circular pipe. Let the thickness of the large cone head end of the tapered expansion triangle solid contraction sleeve 4 be greater than the thickness of the small cone head end, and the front end sleeve of the three-way opening sleeve 8 and the connected solid triangle brace 13 are provided with external threads 7 and locking screws. Cover 12 is screwed together, and the sleeve hole of described sleeve head is a blind hole, and the chamfering of sleeve hole mout...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap