LED driver

A LED driver, the first technology, applied in the direction of lighting devices, light sources, electrical components, etc., can solve the problems that LED drivers cannot meet the height requirements of flat lamps, lamps lose competitiveness, and the cost of magnetic cores is expensive, etc., to achieve high frequency suppression Electromagnetic noise, meeting height requirements, effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

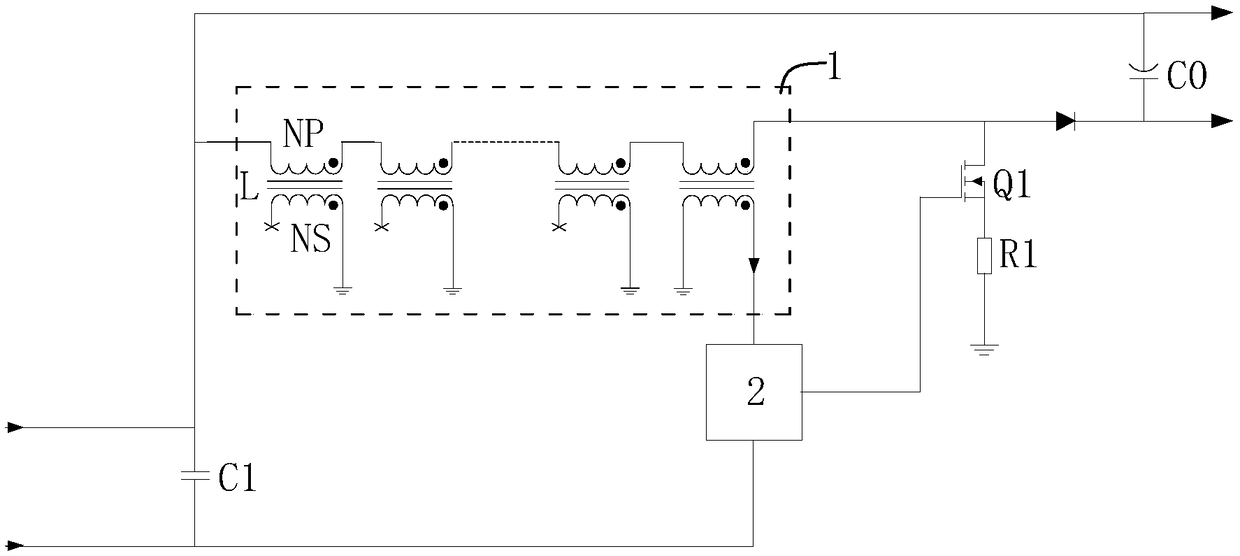

[0022] Such as image 3 As shown, the LED driver in this embodiment includes a first capacitor C1 , a second capacitor C0 , a transistor Q1 , a diode D1 , an energy storage inductor unit 1 and a control circuit board 2 .

[0023] The two ends of the first capacitor C1 are used as the input ends of the LED driver, the two ends of the first capacitor C1 are respectively electrically connected to the power supply, and the first end of the first capacitor C1 is grounded.

[0024] The two ends of the second capacitor C0 are used as the output ends of the LED driver, and the two ends of the second capacitor C0 are respectively electrically connected to the load of the LED lamp, thereby supplying power to the LED lamp.

[0025] The source of the transistor Q1 is grounded through the resistor R1, and the drain of the transistor Q1 is electrically connected to the first end of the second capacitor C0 through the diode D1. That is, the drain of the transistor Q1 is electrically connect...

Embodiment 2

[0033] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is only that: the first power supply connection end of the control chip is connected to the second end of the first capacitor C1 through a peripheral circuit, and then directly supplies power to the control chip through the power supply. During implementation, Only the corresponding peripheral circuits need to be set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com