Environment-friendly PVC modified outdoor sports floor, and preparation technology thereof

A modified and environmentally friendly technology, applied to flat products, other household appliances, applications, etc., can solve the problems of large thermal expansion and contraction ratio, easy to produce foaming, arching, and abnormal use, so as to reduce thermal expansion and cold The effect of shrinking ratio, improving product stability and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

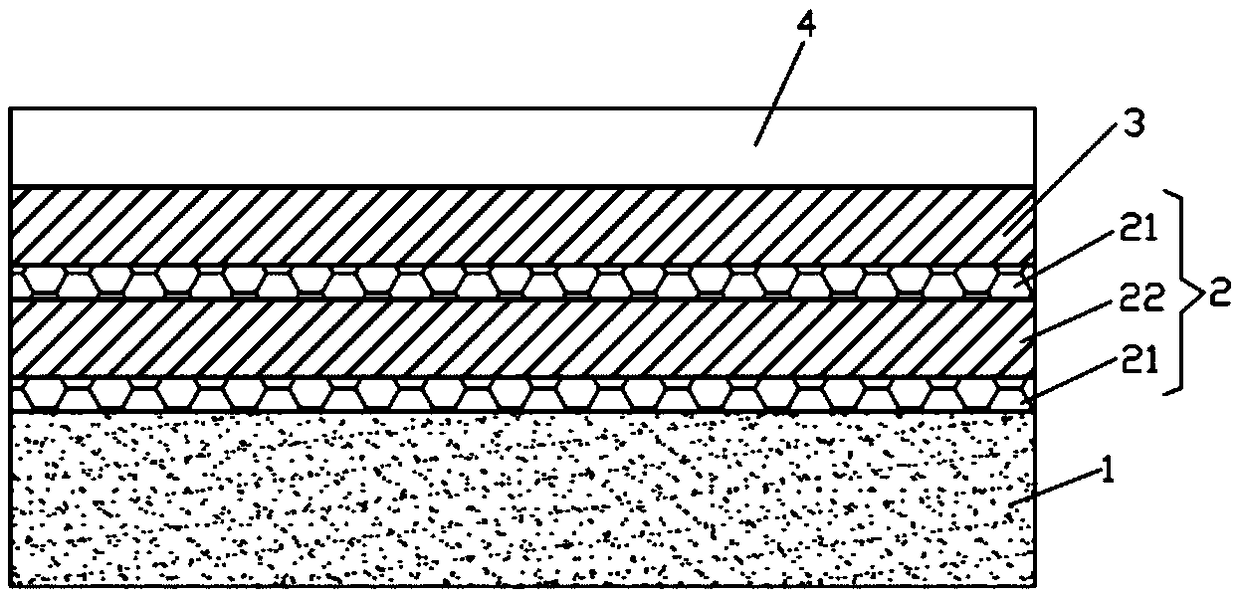

[0024] Such as figure 1 The shown environment-friendly PVC modified outdoor sports floor includes a calcium-free airtight foaming waterproof layer 1, a double-layer polyester cloth stable layer 2, and a PVC wear-resistant sports surface layer 3 arranged sequentially from bottom to top. The double-layer polyester cloth stabilization layer 2 includes a PVC stabilization layer 22 and polyester cloths 21 located on both sides of the PVC stabilization layer 22 . The PVC wear-resistant sports surface layer 3 is also provided with a PVC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com