A method for preparing isopropyl bromide from oxadiazon etherification wastewater

A technology of isopropyl bromide and oxadiazon ether is applied in the field of resource utilization and treatment of production wastewater, which can solve the problems of not meeting the production requirements of safety and environmental protection, the great danger of phosphorus tribromide, and the complicated operation process, and avoid the problem of The effect of post-processing process, reduction of purchase volume, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

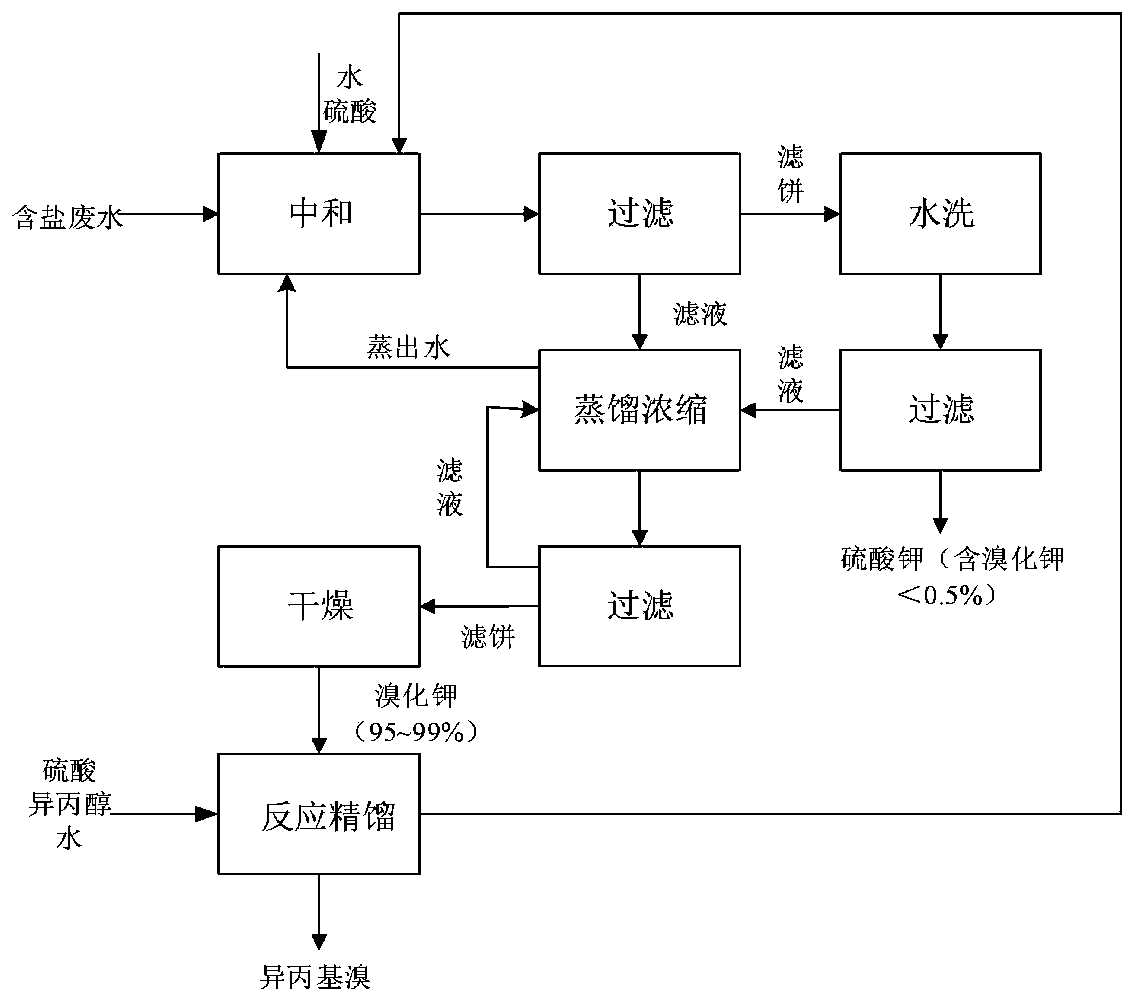

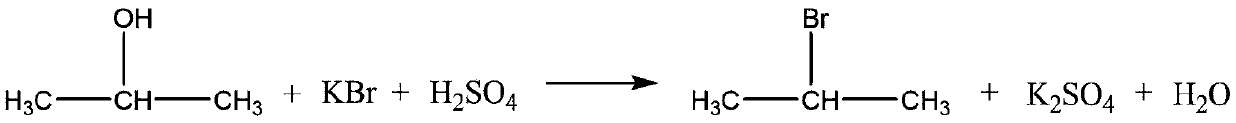

[0046] Take the etherification wastewater and add sulfuric acid or waste acid with a content of 30%-40% to neutralize the solution until the pH of the solution is 5-6, the neutralization temperature is 30°C, and filter at room temperature. Potassium chloride solution.

[0047] Adding 30% water of the mass of etherified wastewater is used for washing the potassium sulfate filter cake to obtain the fine potassium sulfate; the washing solution and the potassium bromide aqueous solution are combined for distillation to concentrate the potassium bromide.

[0048] Add the combined solution of washing liquid and potassium bromide aqueous solution into the reaction flask, heat up and distill, the distillation temperature is 60°C-80°C, the vacuum degree is -0.08MPa-0.05MPa, steam until most of the potassium bromide crystallizes out, cool down, and filter at room temperature , the filtrate enters the neutralization section for recycling, and the filter residue is crude potassium bromide...

Embodiment 2

[0051]The implementation steps are similar to Example 1, the temperature of the neutralization section is controlled below 20° C., and the purified potassium bromide content is more than 98%. The purified potassium bromide is used to synthesize isopropyl bromide, and the yield is 97.5%.

Embodiment 3

[0053] The implementation steps are similar to Example 1, the neutralization temperature is controlled below 20°C, the water volume in the washing section is increased to 60%, the purified potassium bromide content is 99.2%, the synthetic isopropyl bromide has a purity of 99%, and a yield of 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com