Multi-layer composite forming machine for superfine fibers

A super-fine fiber, composite technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of obvious delamination boundaries, poor fiber solid-phase bonding, difficult to guarantee product quality, etc., to ensure the quality of wet forming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

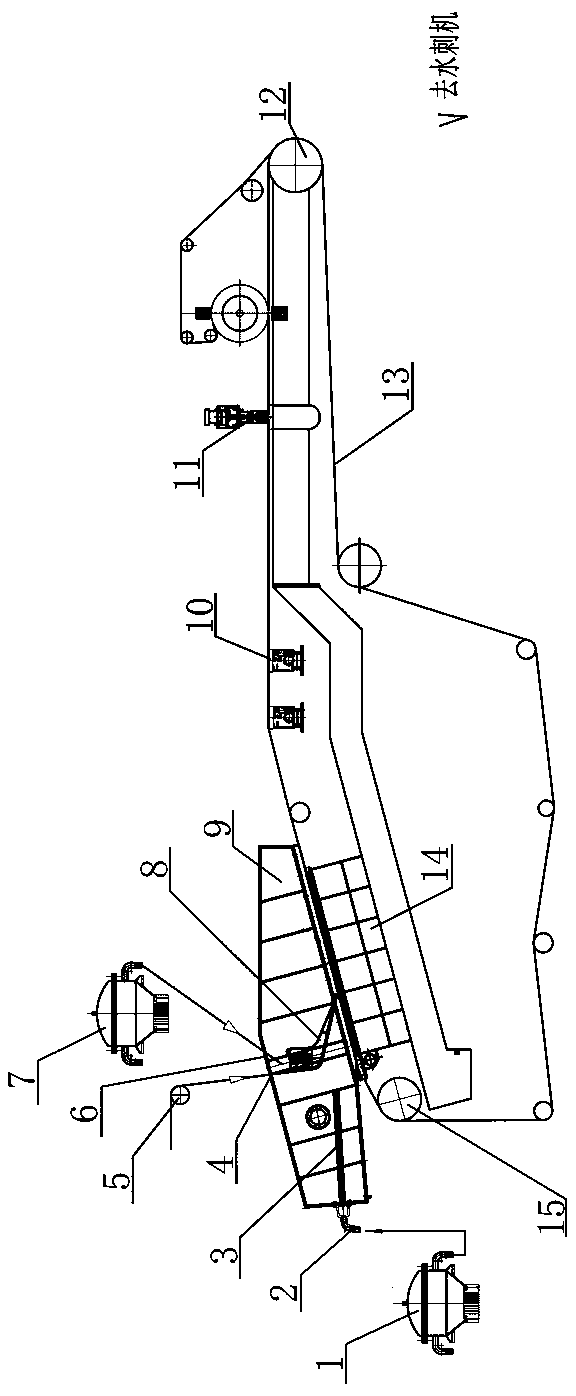

[0013] refer to figure 1 , the present invention is a superfine fiber multi-layer composite forming machine, which includes a former 9 and a dehydrator 14;

[0014] The front end of the former 9 communicates with the fiber inlet I2 through the tube bundle channel 3; the top of the former 9 is provided with the fiber inlet II4 and the fiber inlet III6; the fiber inlet I2, the fiber inlet II4 and the fiber inlet III6 pass through The guide plate 8 communicates with the dehydrator 14 arranged below the former 9;

[0015] The top surface of the dehydrator 14 is provided with a forming mesh conveyor belt 13, and the forming mesh conveyor belt 13 is connected to each other through a driven roller 15 and a driving roller 12; the bottom surface of the forming mesh conveyor belt 13 is attached to the top surface of the dehydrator 14 ; The rear end of the dehydrator 14 is provided with a water suction box 10 and a hydroentanglement machine 11 in sequence.

[0016] Further, the fiber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com