Parameter-controllable single/multiple abrasive particle high-speed etching experimental device

An experimental device, controllable technology, applied in the direction of measurement device, test machinability, instrument, etc., can solve the problem of only considering scribing depth, scribing speed, less contrast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment

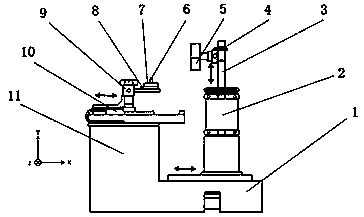

[0041] Such as figure 1As shown, the present invention is a parameter-controllable single / multi-grain high-speed scoring experimental device, including a spindle workbench 1, a spindle motor and a control system 2, a spindle 3, a Y-direction linear motion mechanism 4, and a dynamometer 4. Rotary disc 5, diamond scoring device 6, force measuring instrument 7, fixture plate 8, adapter plate 9, precision mobile workbench 10, bed 11, the specific implementation plan includes the following steps:

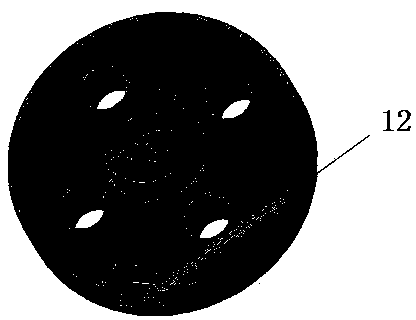

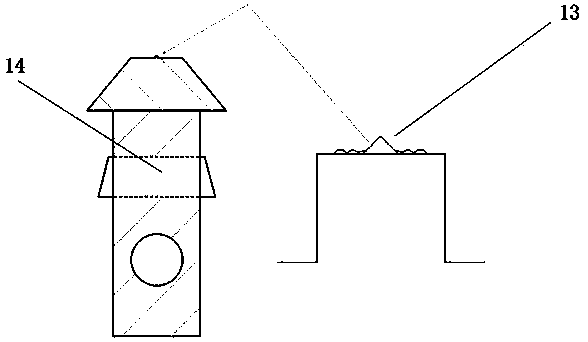

[0042] Step 1: Preparation of diamond abrasive tools: According to the experimental requirements, at least three groups of single / multiple abrasive diamond scoring tools need to be prepared. The diamond abrasive grains are uniformly selected with a cone angle of 90 o A cone with a particle size of 60, the maximum particle size is 253µm, and the average partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com