Rapid and convenient evaluation method for heat storage stability of lithium ion battery positive electrode material

A thermal storage stability, lithium-ion battery technology, applied in the direction of thermal expansion coefficient of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

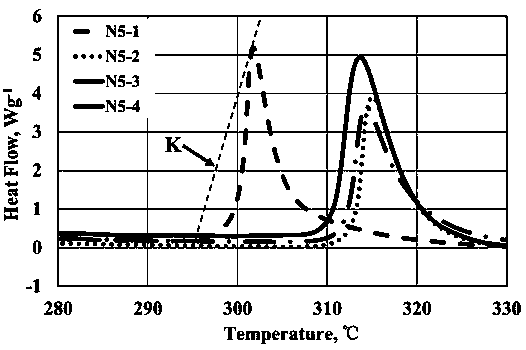

Embodiment 1

[0039] Four kinds of nickel-cobalt lithium manganese oxide NCM523 ternary cathode materials prepared by a similar process were selected, and the positive electrode sheets were made respectively according to the active material content of 95wt.%. And use the same electrolyte, separator and half-cell accessories to assemble four batches of button half-cells.

[0040]The above four batches of button half batteries were activated by constant current and constant voltage charge and discharge cycle in the range of 3.0~4.35V respectively. The charge and discharge system is as follows: 0.1C charge and discharge for 2 weeks, 0.2C charge and discharge for 1 week, 0.5C charge and discharge for 1 week, 1.0C charge and discharge for 1 week and 2.0C charge and discharge for 1 week, a total of 6 weeks. After the cycle activation is completed, it is charged to 4.35V at a constant current and constant voltage at a rate of 0.1C, and the cut-off current of constant voltage charging is 0.01C.

...

Embodiment 2

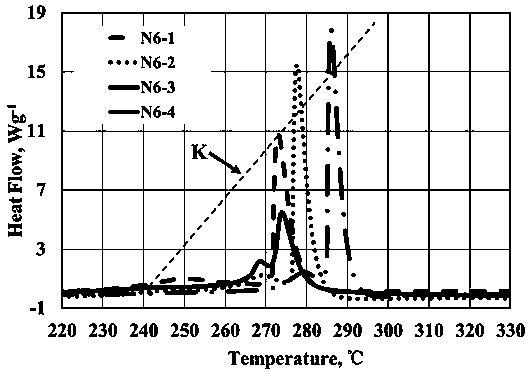

[0053] Four kinds of nickel-cobalt lithium manganese oxide NCM622 ternary cathode materials prepared by a similar process were selected, and the positive electrode sheets were respectively made according to the active material content of 92wt.%. And use the same electrolyte, separator and half-cell accessories to assemble four batches of button half-cells.

[0054] The above four batches of button half-cells were activated by constant current and constant voltage charge and discharge cycle in the range of 3.0~4.30V respectively. The charge and discharge system is as follows: 0.1C charge and discharge for 2 weeks, 0.2C charge and discharge for 1 week, 0.5C charge and discharge for 1 week, 1.0C charge and discharge for 2 weeks, 2.0C charge and discharge for 1 week, 5.0C charge and discharge for 1 week and 1.0C charge and discharge 1 week of discharge for a total of 9 weeks. After the cycle activation is completed, it is charged to 4.30V at a constant current and constant voltag...

Embodiment 3

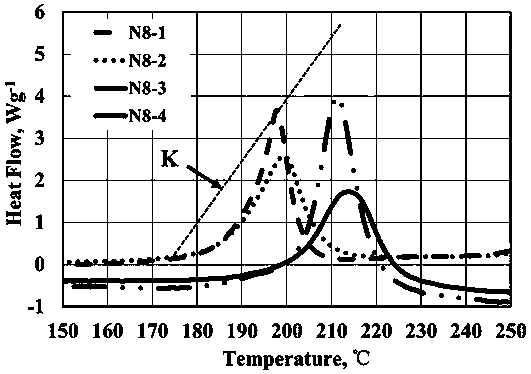

[0066] Four kinds of nickel-cobalt lithium manganese oxide NCM811 ternary cathode materials prepared by a similar process were selected, and the positive electrode sheets were made respectively according to the active material content of 90wt.%. And use the same electrolyte, separator and half-cell accessories to assemble four batches of button half-cells.

[0067] The above four batches of button half batteries were activated by constant current and constant voltage charge and discharge cycle in the range of 3.0~4.25V respectively. The charge and discharge system is as follows: 0.1C charge and discharge for 2 weeks, 0.2C charge and discharge for 2 weeks, 0.5C charge and discharge for 2 weeks, 1.0C charge and discharge for 2 weeks, 2.0C charge and discharge for 2 weeks, 5.0C charge and discharge for 1 week and 1.0C charge and discharge 1 week of discharge for a total of 12 weeks. After the cycle activation is completed, it is charged to 4.25V at a constant current and constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com