Virtual sensor array and preparation method thereof

A virtual sensor, sensor technology, applied in the direction of material resistance, can solve the problems of high power consumption, large volume, complex structure, etc., to achieve the effect of reducing power consumption, small size, and reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present disclosure will be described in detail below with reference to the drawings and embodiments.

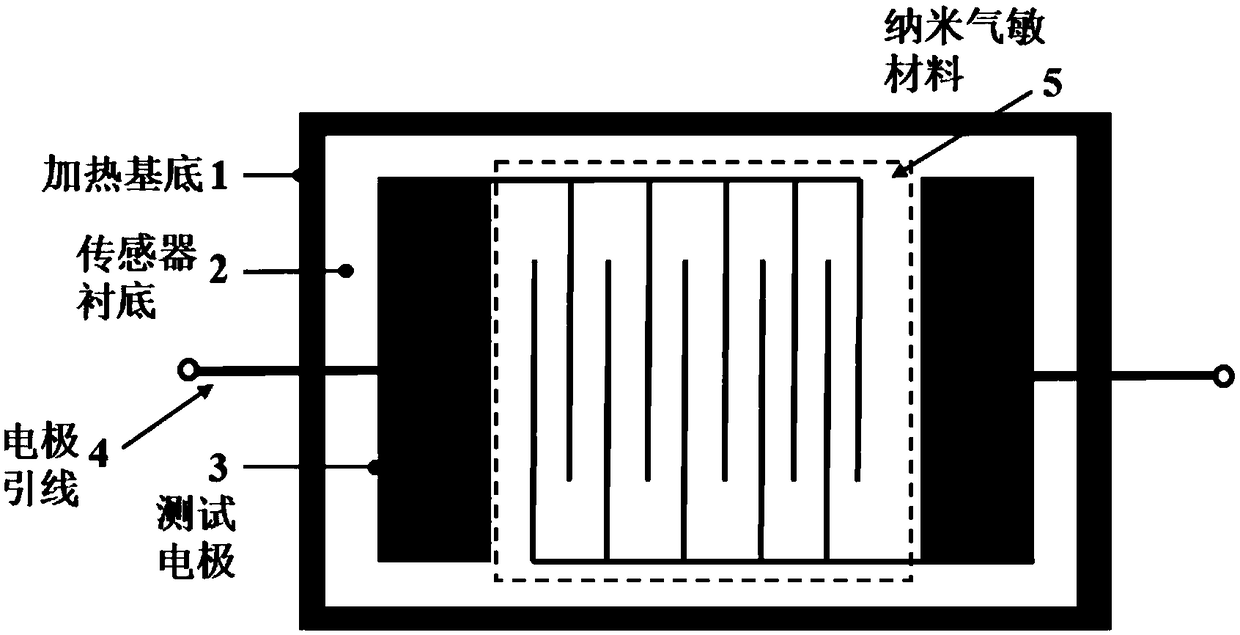

[0034] see figure 1 , a virtual sensor array, including a heating substrate 1, a sensor substrate 2, a test electrode 3 and a nano gas-sensitive material 5; wherein,

[0035] The sensor substrate 2 is placed on the heating base 1;

[0036] The test electrode 3 is engraved on the sensor substrate 2;

[0037] The test electrode 3 leads to an electrode lead 4;

[0038] The nanometer gas sensitive material 5 is coated on the central area of the surface of the test electrode 3 .

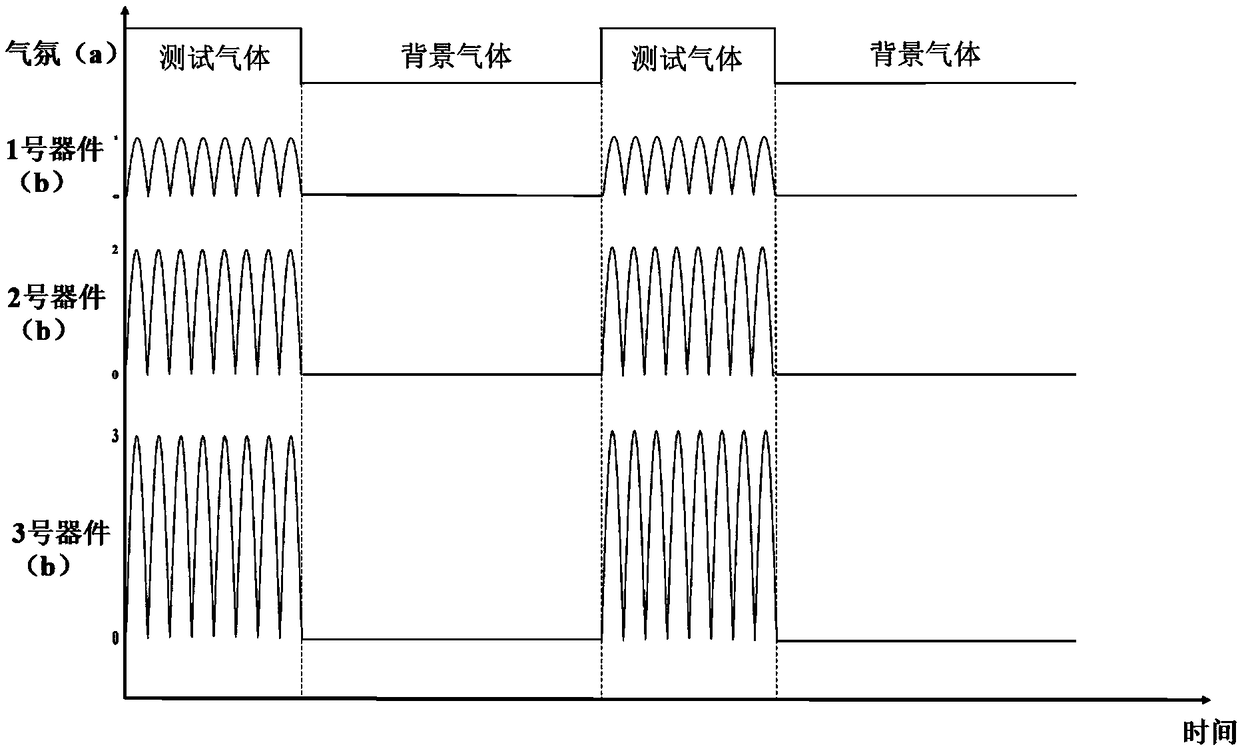

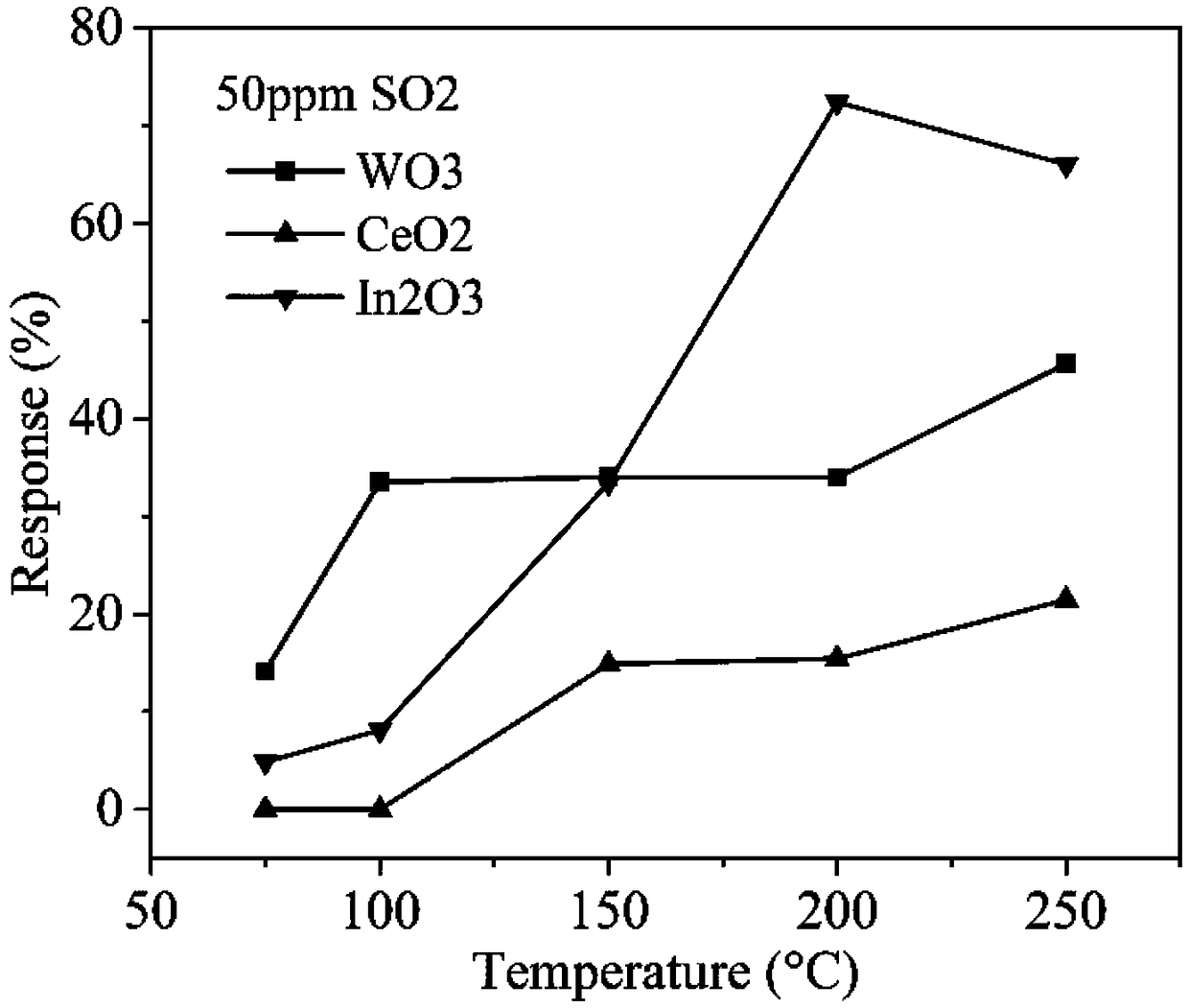

[0039] The above-mentioned embodiment completely discloses the technical solution of the present invention. The virtual sensor array is prepared by using the temperature characteristics of different nano-gas sensitive materials 5 in response to gases, which has the characteristics of greatly reducing the scale of the sensor array and reducing the overall volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com