High-humidity low-concentration dust generating device

A technology of dust generation and low concentration, applied in the direction of measuring device, multiple fluid ratio control, standard gas analyzer, etc., can solve the problem of not being suitable for the simulation of high-humidity and low-concentration dust conditions, and it is difficult to truly simulate the conditions of wet desulfurization dust , Failure to truly simulate the dust working conditions, etc., to achieve the effects of controllable water vapor content, controllable sample gas temperature, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

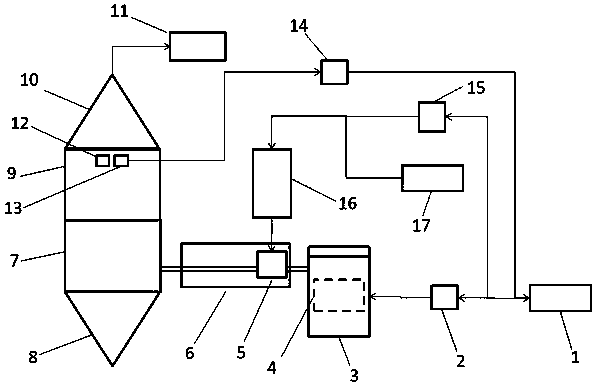

[0026] Such as figure 1 As shown, a high-humidity and low-concentration dust generation device is mainly composed of an air compressor 1, an atomization device 3, a sample gas heating device 6, a sample gas detection device, a dilution heating device 16, other gas distribution devices 17, an exhaust device 11 and a flow control system; the control system includes a main controller and a sample flow control device 2 connected to the main controller, a sampling flow control device 14 and a dilution flow control device 15; the sample gas The detection device is sequentially provided with an air outlet 10, an observation chamber 9, an air inlet chamber 7 and a waste liquid outlet chamber 8 from top to bottom; the air outlet 10 is connected with the exhaust device 11; A mixed liquid chamber 4 containing the mixed liquid; the atomization device 3 is also provided with an air inlet pipe and an air outlet arranged on the top, wherein one end of the air inlet pipe is set in the mixed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com