Precious metal recovery device for titanium anode coating process

A technology of precious metal recovery and titanium anode, which is applied to the surface coating liquid device, coating, etc., can solve the problems of precious metal solution dripping and spilling difficult to recycle, and achieve the effect of avoiding waste and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

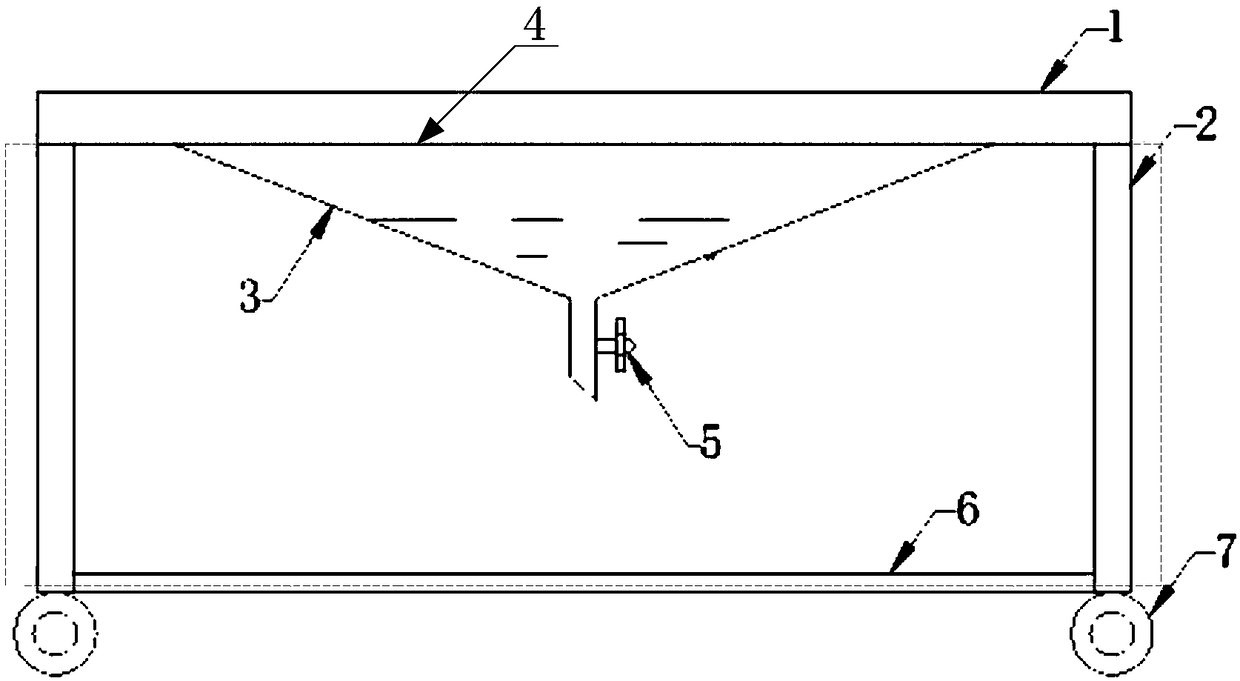

[0021] see figure 1 As shown, the present invention provides a precious metal recovery device for the brushing process of titanium anodes, comprising: a device support 4, a conical container 3 fixed on the device support 4, and a valve is installed at the outlet below the conical container 3 5. A placing plate 1 is provided above the conical container 3, and the placing plate 1 is fixedly connected with the device bracket 4.

[0022] Further, the placing plate 1 is a grid-shaped placing plate, on which the titanium substrate can be placed to paint the precious metal solution.

[0023] Further, rollers 7 are installed on the bottom of the device support 4 to facilitate the movement of the precious metal recovery device.

[0024] Further, the roller 7 is provided with a roller lock, and when the precious metal recovery device moves to the titanium anode coating workshop, the roller lock is locked to fix the precious metal recovery device.

[0025] Further, the conical containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com