Automatic joint device and process for one-step forming of inner rib pipe

The technology of a joint device and an inner rib tube is applied to the field of automatic joint device for one-time forming of inner rib tube, which can solve the problems of low welding efficiency, many labors, limiting the production efficiency of finished pipes, etc., and achieves improved work efficiency, smooth interface and improved welding. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

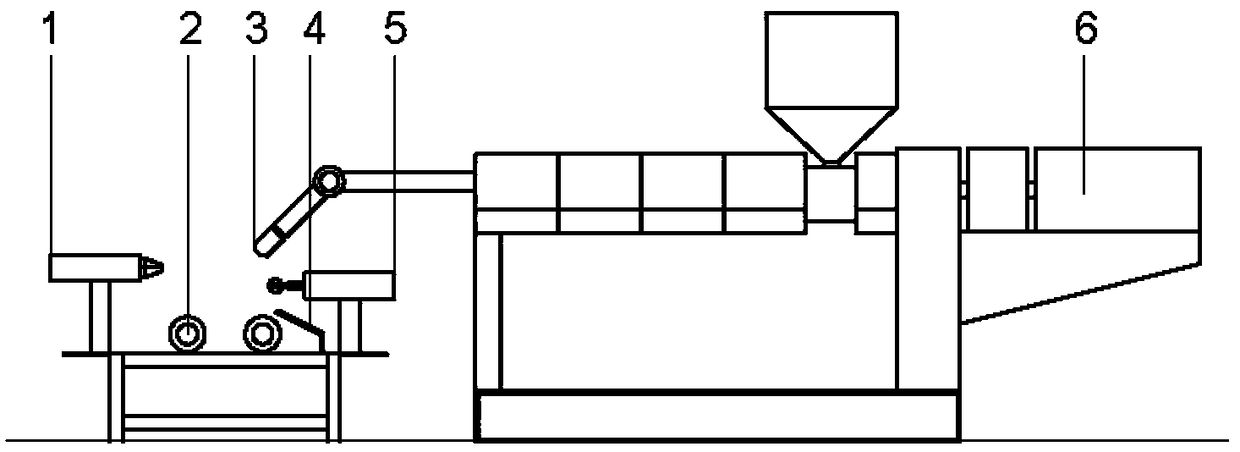

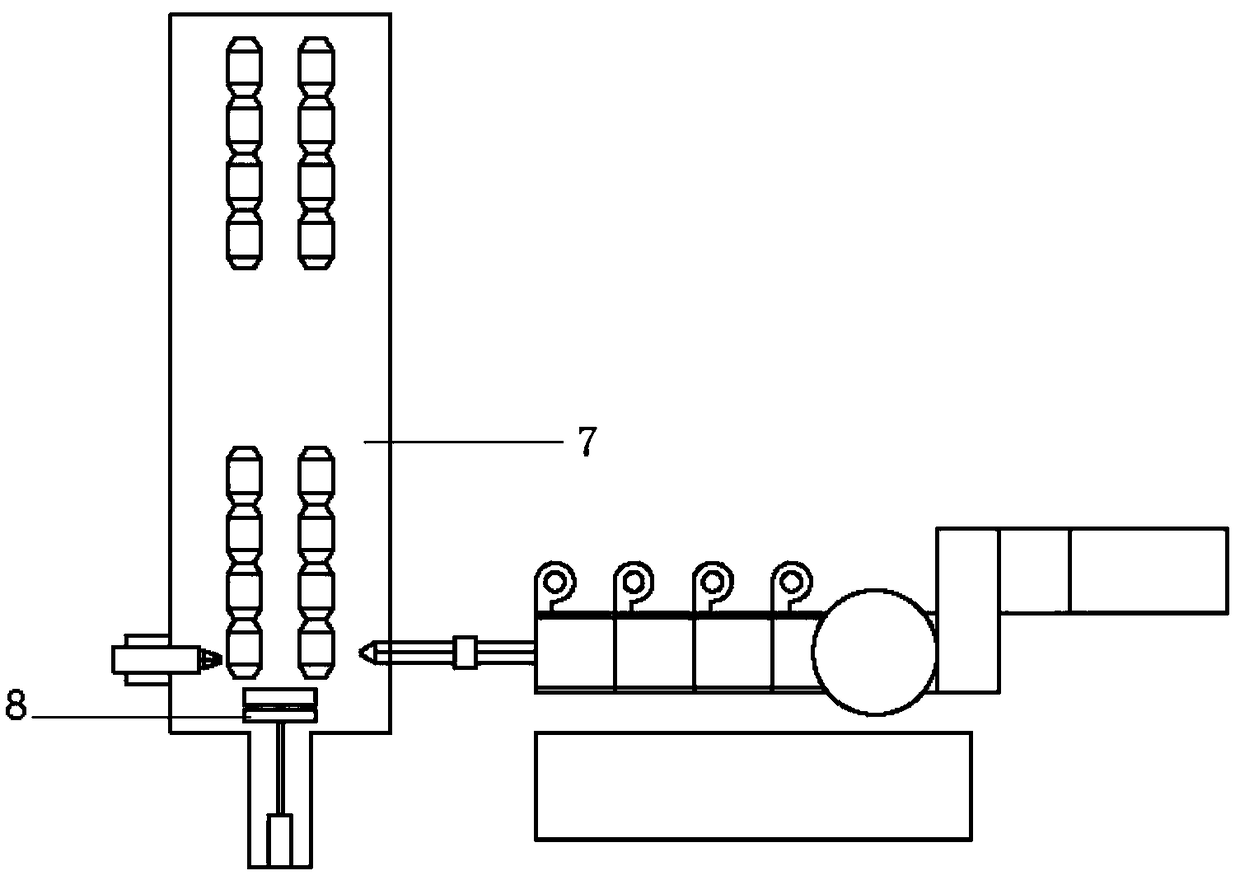

[0025] A joint system device for one-time forming of inner ribbed tubes, including: a heat gun, a transmission roller, a discharge die, a spray water pipe, a pressure wheel, an extruder, an electric three-jaw chuck, and a rolling frame; wherein, the discharge die Set on one side of the extruder, the electric three-jaw chuck, transmission roller, pressure wheel, heat gun, and spray water pipe are all set on the rolling frame, and the electric three-jaw chuck is located at the end of the rolling frame close to the extruder. The heat gun is located on the side of the tumble frame away from the discharge die. Among them, the heat gun is used to heat the welding part of the inner rib tube, the transmission roller is used to convey the plastic tube, and the discharge die is used to transfer the extruded PE melt to the gap between the inner rib tube and the socket, spray The water spray pipe is used to spray cooling water, the pressure roller is used to compress the welding seam, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com