High-temperature steaming and boiling casting polypropylene film

A technology of casting polypropylene and high-temperature cooking, applied in the field of plastic film, can solve the problems of easily broken bags, peeling strength and heat-sealing strength, affecting customers' use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

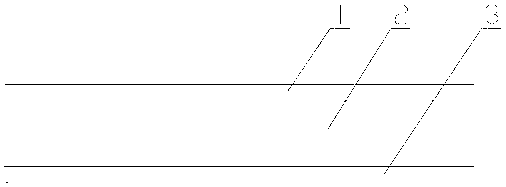

[0009] The specific embodiment of the present invention will be described below in conjunction with accompanying drawing, as figure 1 Shown: a high-temperature cooking type cast polypropylene film, which is a three-layer structure, from top to bottom is a corona layer 1, an intermediate layer 2 and a heat-sealing layer 3, wherein the corona layer 1 contains 85-98% of Block copolymer polypropylene and 2-15% polyolefin elastomer, middle layer 2 contains 85-98% block copolymer polypropylene and 2-15% polyolefin elastomer, heat seal layer 3 contains 78-96% block copolymerized polypropylene, 2-15% polyolefin elastomer and 2-7% silicone smooth masterbatch, the above ratios are all percentages by mass, and the corona layer 1, the middle layer 2 and the heat-sealing layer 3 The thickness ratio is 1:2-4:1-2.

[0010] The high-temperature retort-type cast polypropylene film of the embodiment of the present invention uses high-melting point block copolymer polypropylene as the main mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com