A pipe joint and its preparation method

A technology of pipe joints and weight percentages, which is applied in the field of pipe joints and its preparation, can solve problems such as harsh deep-sea environments, and achieve the effects of improving strength and plasticity, improving corrosion resistance, and improving low-temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A pipe joint, its chemical composition and weight percentage are: carbon 0.27%, manganese 0.66%, phosphorus ≤ 0.020%, sulfur ≤ 0.015%, silicon 0.13%, nickel 0.72%, chromium 0.81%, molybdenum 0.33%, aluminum 0.01% , niobium 0.015%, vanadium 0.03%, copper ≤ 0.15%, the balance is iron and unavoidable impurities. The total amount of copper, niobium, aluminum, vanadium and unavoidable impurities is less than or equal to 1.00%. The unavoidable impurities include nitrogen, oxygen, and hydrogen, wherein nitrogen≤100ppm, oxygen≤30ppm, and hydrogen≤1.6ppm.

[0034] The preparation method of the above-mentioned pipe joint comprises the following steps:

[0035] (1) Smelting, using electric furnace smelting, ladle furnace refining, vacuum casting, vacuum degassing and electroslag remelting;

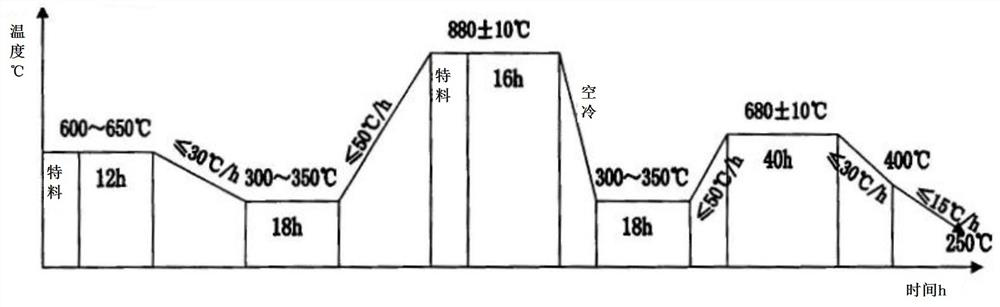

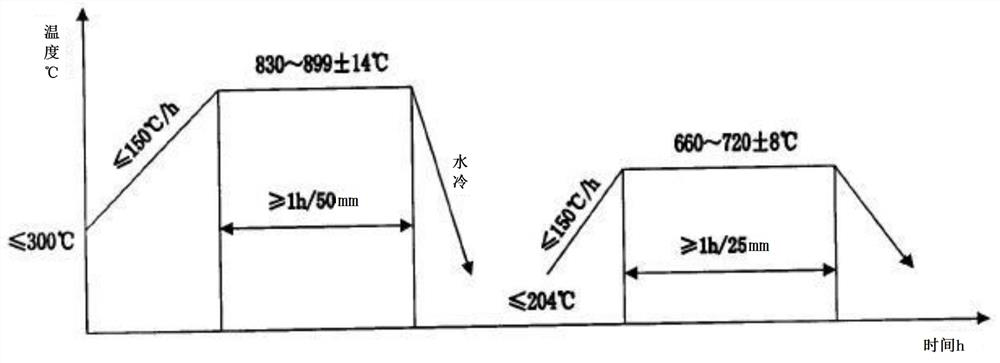

[0036] (2) Forging; 10,000 tons of hydraulic press is used for free forging, the initial forging temperature is 1250°C, the final forging temperature is 750°C, and the forging ratio is 5; the...

Embodiment 2

[0040]A pipe joint, its chemical composition and weight percentage are: carbon 0.34%, manganese 1.09%, phosphorus ≤ 0.020%, sulfur ≤ 0.015%, silicon 0.37%, nickel 0.93%, chromium 1.09%, molybdenum 0.47%, aluminum 0.031% , niobium 0.035%, vanadium 0.06%, copper ≤ 0.15%, the balance is iron and unavoidable impurities. The total amount of copper, niobium, aluminum, vanadium and unavoidable impurities is less than or equal to 1.00%. The unavoidable impurities include nitrogen, oxygen, and hydrogen, wherein nitrogen≤100ppm, oxygen≤30ppm, and hydrogen≤1.6ppm.

[0041] The preparation method of the above-mentioned pipe joint comprises the following steps:

[0042] (1) Smelting, using electric furnace smelting, ladle furnace refining, vacuum casting, vacuum degassing and electroslag remelting;

[0043] (2) Forging: 10,000-ton hydraulic press is used for free forging, the initial forging temperature is 1200°C, the final forging temperature is 800°C, and the forging ratio is 5; the fir...

Embodiment 3

[0047] A pipe joint, its chemical composition and weight percentage are: carbon 0.30%, manganese 0.88%, phosphorus ≤ 0.020%, sulfur ≤ 0.015%, silicon 0.23%, nickel 0.80%, chromium 0.90%, molybdenum 0.40%, aluminum 0.020% , niobium 0.022%, vanadium 0.04%, copper ≤ 0.15%, the balance is iron and unavoidable impurities. The total amount of copper, niobium, aluminum, vanadium and unavoidable impurities is less than or equal to 1.00%. The unavoidable impurities include nitrogen, oxygen, and hydrogen, wherein nitrogen≤100ppm, oxygen≤30ppm, and hydrogen≤1.6ppm.

[0048] The preparation method of the above-mentioned pipe joint comprises the following steps:

[0049] (1) Smelting, using electric furnace smelting, ladle furnace refining, vacuum casting, vacuum degassing and electroslag remelting;

[0050] (2) Forging; 10,000 tons of hydraulic press is used for free forging, the initial forging temperature is 1250°C, the final forging temperature is 750°C, and the forging ratio is 5; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com