A kind of low temperature impact resistant epoxy adhesive composition and preparation method thereof

A technology of epoxy adhesives and compositions, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as brittle cracks, poor toughness, and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

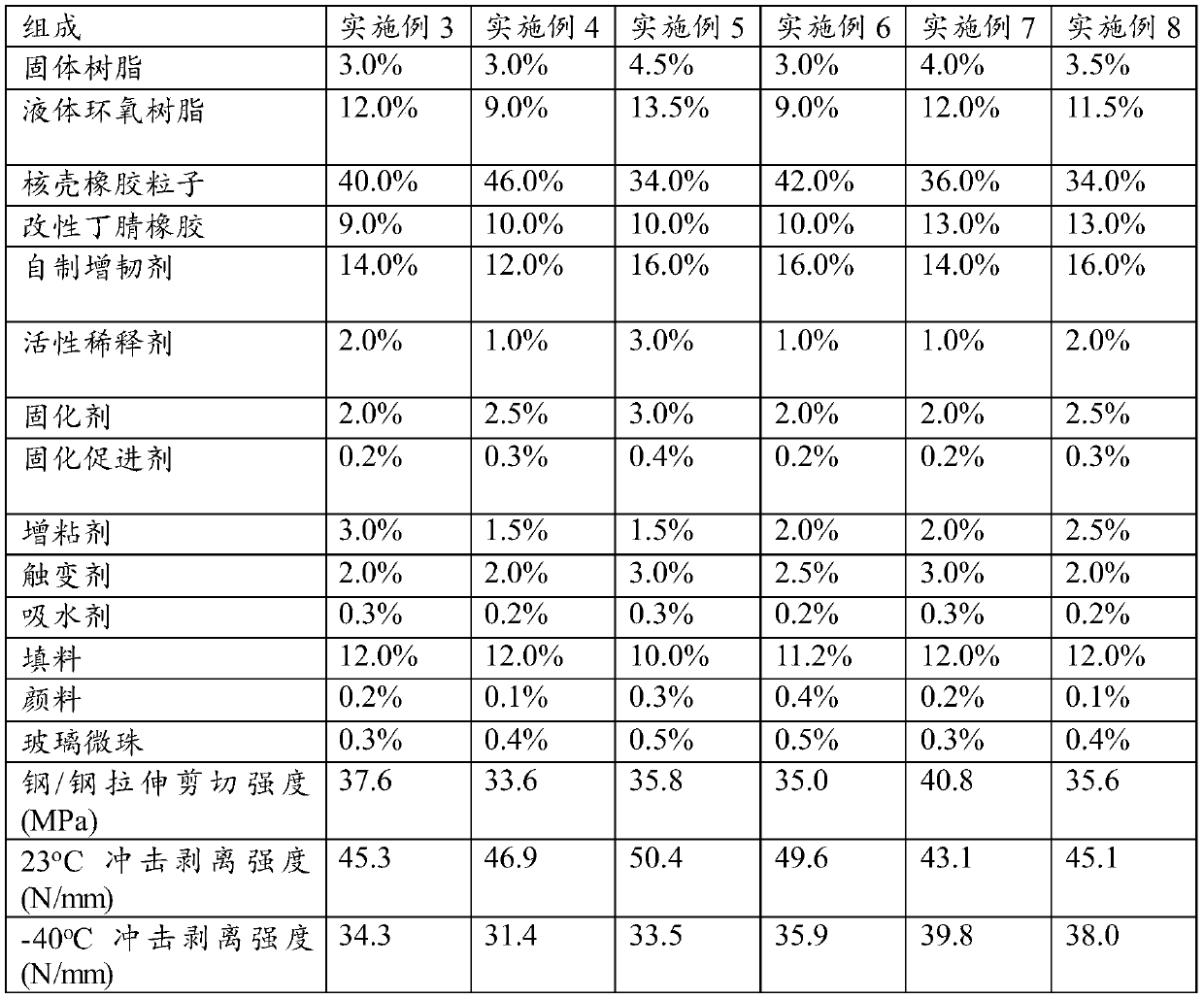

Examples

preparation example Construction

[0079] The present invention also provides a kind of preparation method of above-mentioned epoxy adhesive composition, comprises the following steps:

[0080] A) heating and melting the epoxy resin after mixing to obtain the epoxy resin mixture;

[0081] B) Add difunctional epoxy diluent, toughening agent, inorganic filler, dewatering agent, thixotropic agent, heat-activated latent curing agent and curing accelerator to mixing and stirring in the epoxy resin mixture, vacuum Degassing to obtain an epoxy adhesive composition.

[0082] In the present invention, firstly, the epoxy resin is mixed and then heated and melted to obtain the epoxy resin mixed liquid.

[0083] Specifically, heating the liquid epoxy resin to 95-105°C, adding the solid epoxy resin, mixing and stirring until the solid epoxy resin melts to obtain the epoxy resin mixture;

[0084] Next, add difunctional epoxy diluent, toughening agent, inorganic filler, dewatering agent, thixotropic agent, heat-activated la...

Embodiment 1

[0090] The preparation of embodiment 1 toughening agent A

[0091] Add 100 parts of polyether polyol (DL-2000D) with a molecular weight of 2000D to the reactor, dehydrate at 105°C for 30 minutes, then add 0.6 parts of trimethylolpropane and 0.1 parts of organotin catalyst, mix well, and add 26.5 parts of MDI, the temperature was adjusted to 85-90° C., and the reaction was carried out for 2.0 hours under this condition to obtain a prepolymer. The mass percent content of —NCO groups in the prepolymer was detected to be 3.3%. Add 10.1 parts of butanone oxime according to the molar ratio of the ketoxime group to the -NCO group of 1.1:1, and perform a capping reaction at 85-90°C for 1.5 hours. The content of the -NCO group in the product is detected to be zero, and the increase Toughener A.

[0092] The number average molecular weight of the toughening agent A was determined to be 4500, the weight average molecular weight was 11000, and the dispersion index was 2.4.

Embodiment 2

[0093] The preparation of embodiment 2 toughening agent B

[0094] Add 200 parts of polyether polyol (DL 4000D) with a molecular weight of 4000D to the reactor, dehydrate at 105°C for 30 minutes, then add 1.0 part of trimethylolpropane and 0.2 part of organotin catalyst and mix well, add MDI28 under nitrogen protection part, adjust the temperature to 85-90° C., and react under this condition for 2.5 hours to obtain a prepolymer. The content of —NCO groups in the prepolymer was detected to be 1.9%. Add 13 parts of cyclohexanone oxime according to the molar ratio of the ketoxime group to the -NCO group of 1.1:1, and perform a capping reaction at 85 to 90°C for 1.5 hours, and detect that the content of the -NCO group in the product is zero, and obtain Toughener B.

[0095] The number average molecular weight of the toughening agent B was determined to be 8600, the weight average molecular weight was 22000, and the dispersion index was 2.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com