A three-motor wire control steering system and its control method

A technology of wire-controlled steering and control methods, applied in electric steering mechanisms, steering mechanisms, power steering mechanisms, etc., can solve the problems of slow motor response speed, slow steering response rate, complex structure, etc., to avoid frequent forward and reverse rotation, Strong safety and reliability, the effect of improving the response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings, but the protection scope of the present invention is not limited thereto.

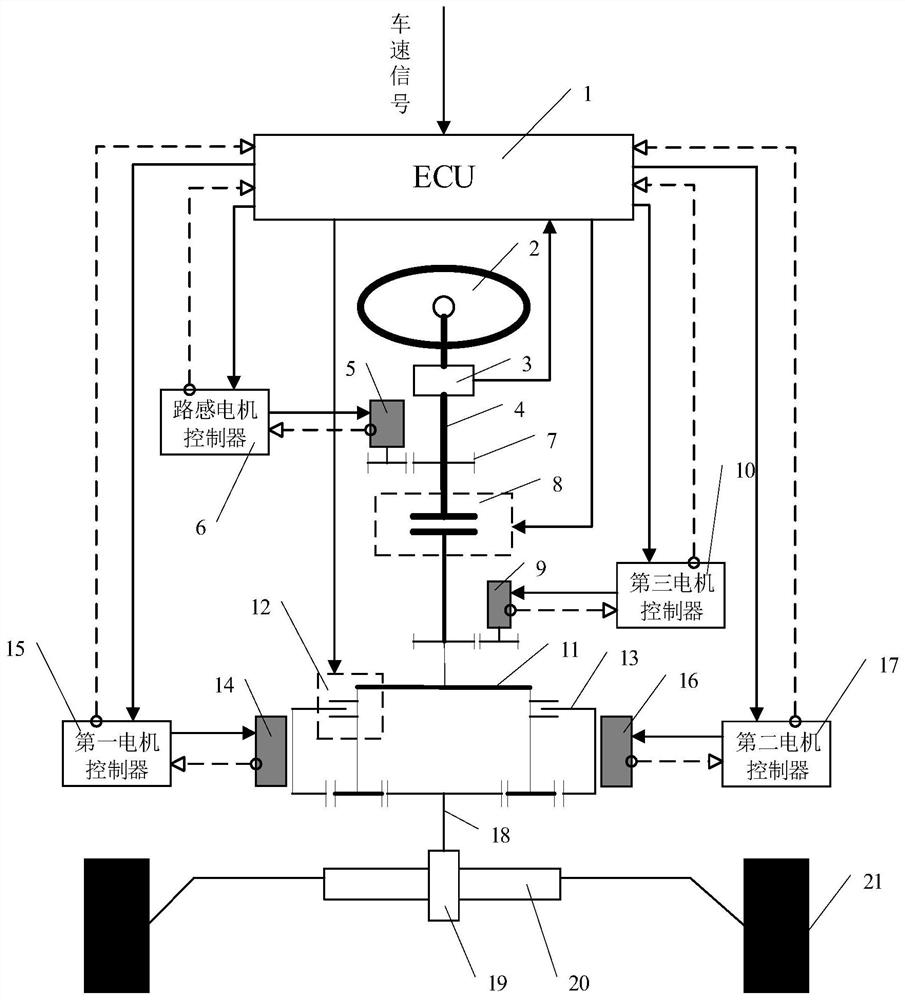

[0040] figure 1 Shown is a three-motor steering-by-wire steering system that takes into account both response rate and reliability, including a steering wheel module, a steering module, and an ECU control module.

[0041] The steering wheel module is composed of a steering wheel 2, a corner torque sensor 3, a steering rod 4, a road sensor motor 5 and a reducer 7, and is used for the driver to operate and control the steering of the vehicle, and to send the steering wheel angle signal and steering wheel to the ECU control module. The torque signal of the rod, while the road sense motor 5 output torque provides the driver with steering road sense; the steering wheel 2 is connected with the first clutch 8 through the steering rod 4, and the corner torque sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com