Energy-saving sewage precipitation device

A sedimentation device and sewage technology, applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of reducing the effect of flocculation and sedimentation and sedimentation efficiency, more electric energy, and consumption. Achieve good flocculation and sedimentation effect, improve mixing uniformity, and improve mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

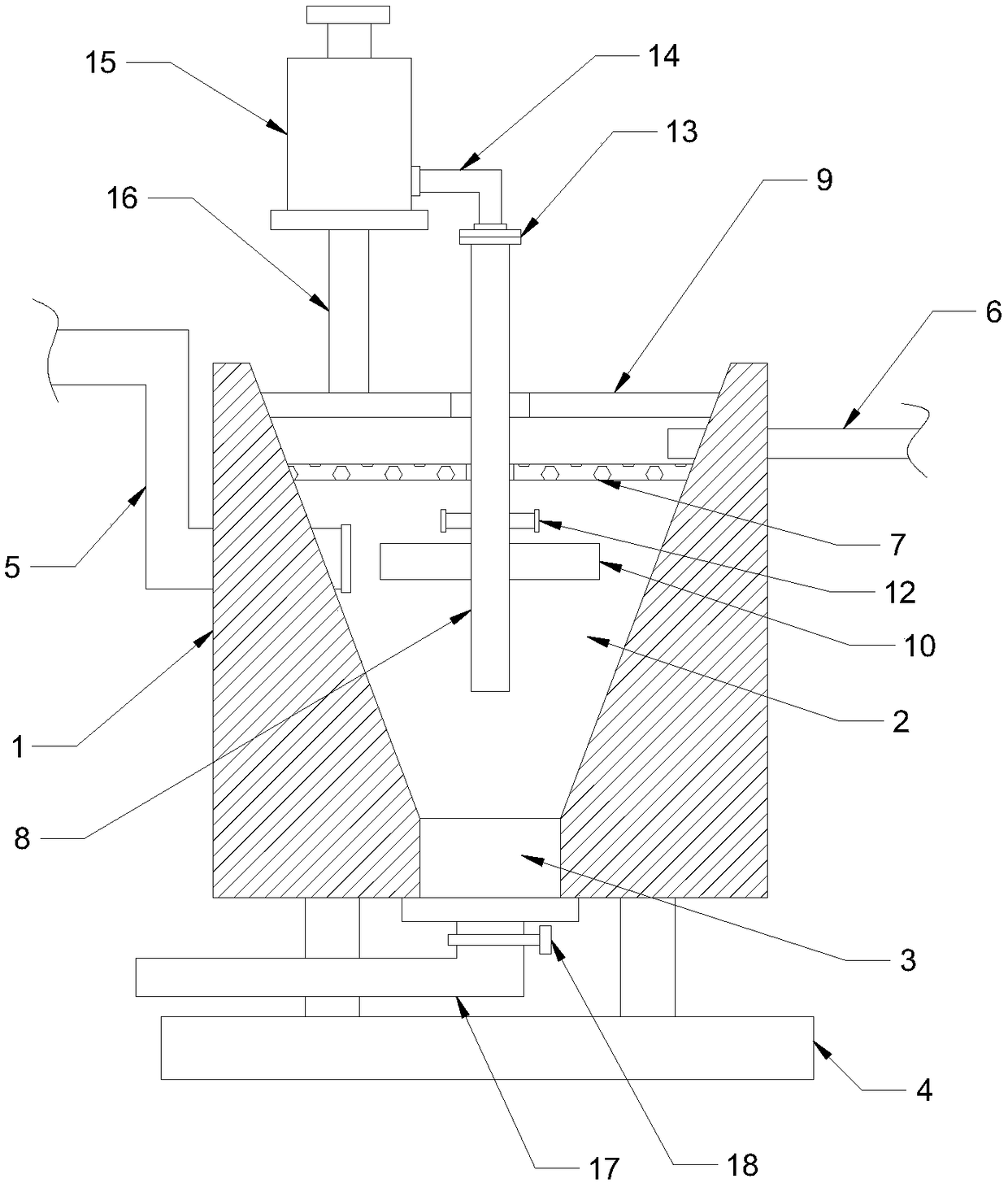

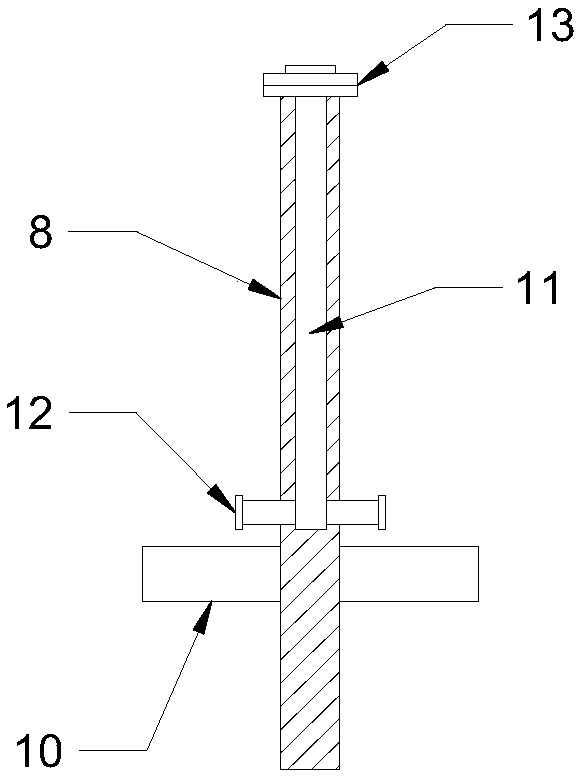

[0021] see Figure 1~2 , in an embodiment of the present invention, an energy-saving sewage sedimentation device includes a sedimentation tank 1 fixedly connected with a base 4; the sedimentation tank 1 is provided with a conical cavity 2, the conical cavity 2 is an inverted conical structure, and the cone The shaped chamber 2 is connected with a sludge chamber 3; the left side of the settling tank 1 is fixedly connected with a water inlet pipe 5, and the water inlet pipe 5 is connected tangentially with the conical chamber 2, and the sewage enters the conical chamber 2 from the water inlet pipe 5 to form a swirling flow , while accelerating the sedimentation of large particles of sludge, an overflow pipe 6 is arranged above the water inlet pipe 5, and a filter screen 7 is arranged between the overflow pipe 6 and the water inlet pipe 5, and the filter screen 7 is fixedly connected with the inner wall of the tapered cavity 2, and the filter screen 7. Filter the overflowing sewa...

Embodiment 2

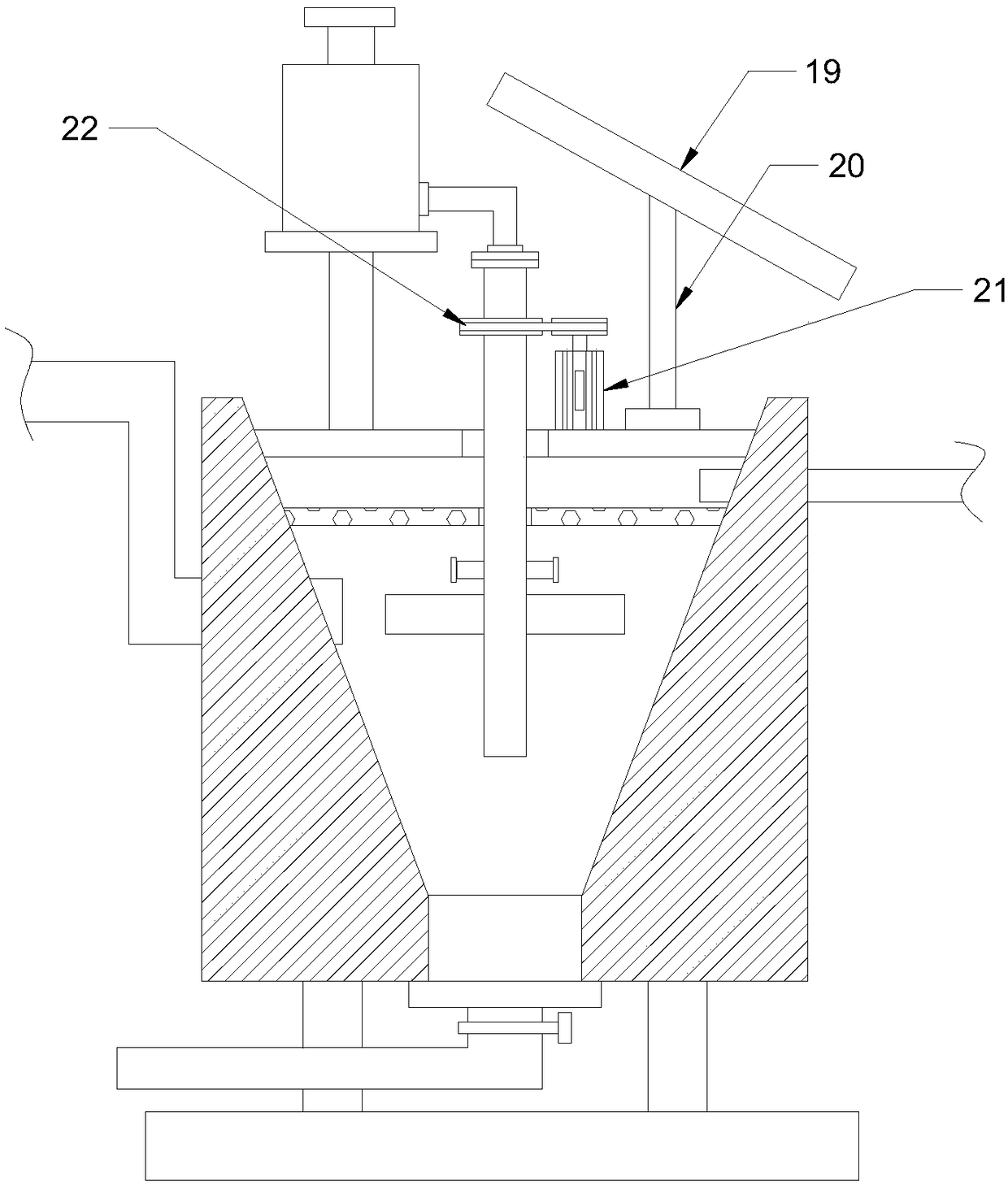

[0025] see image 3 The difference between this embodiment and Embodiment 1 is that the central shaft 8 is connected to the output shaft of the drive motor 21 through the transmission belt 22, the drive motor 21 is fixedly connected with the mounting beam 9 by means of bolts, and the drive motor 9 drives the center The shaft 8 rotates to increase the rotation speed of the stirring plate and improve the mixing effect; above the drive motor 21, a solar panel 19 fixedly connected to the installation beam 9 through the second support frame 20 is arranged, and the solar panel 19 is electrically connected to a storage battery for storing electric energy , the storage battery supplies power to the driving motor 21 to realize environmentally friendly power supply and improve the flocculant diffusion effect at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com