Easily poached and dyed PC/ABS composite material and preparation method thereof

A composite material and ABS resin technology, which is applied in the field of PC/ABS composite material and its preparation, can solve the problems of high rigidity of polycarbonate molecular chain, negative material fluidity, high molding temperature, etc., and achieve good flow performance and color fastness The effect of increasing the temperature and reducing the processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

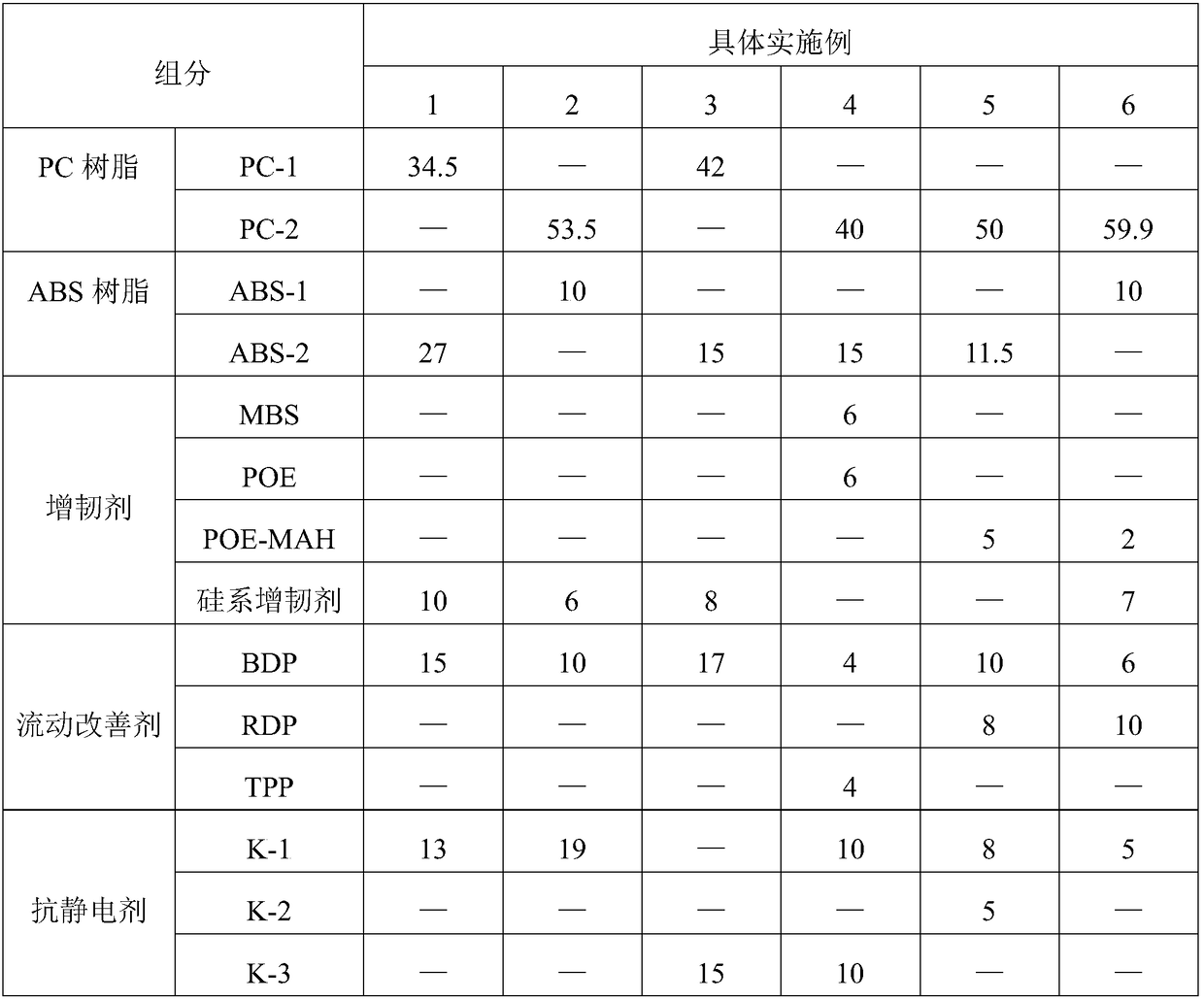

[0028] The PC / ABS composite material of specific examples 1-6 was prepared according to the formula described in Table 1.

[0029] Table 1 specific embodiment 1-6 each component consumption (unit: wt.%)

[0030]

[0031]

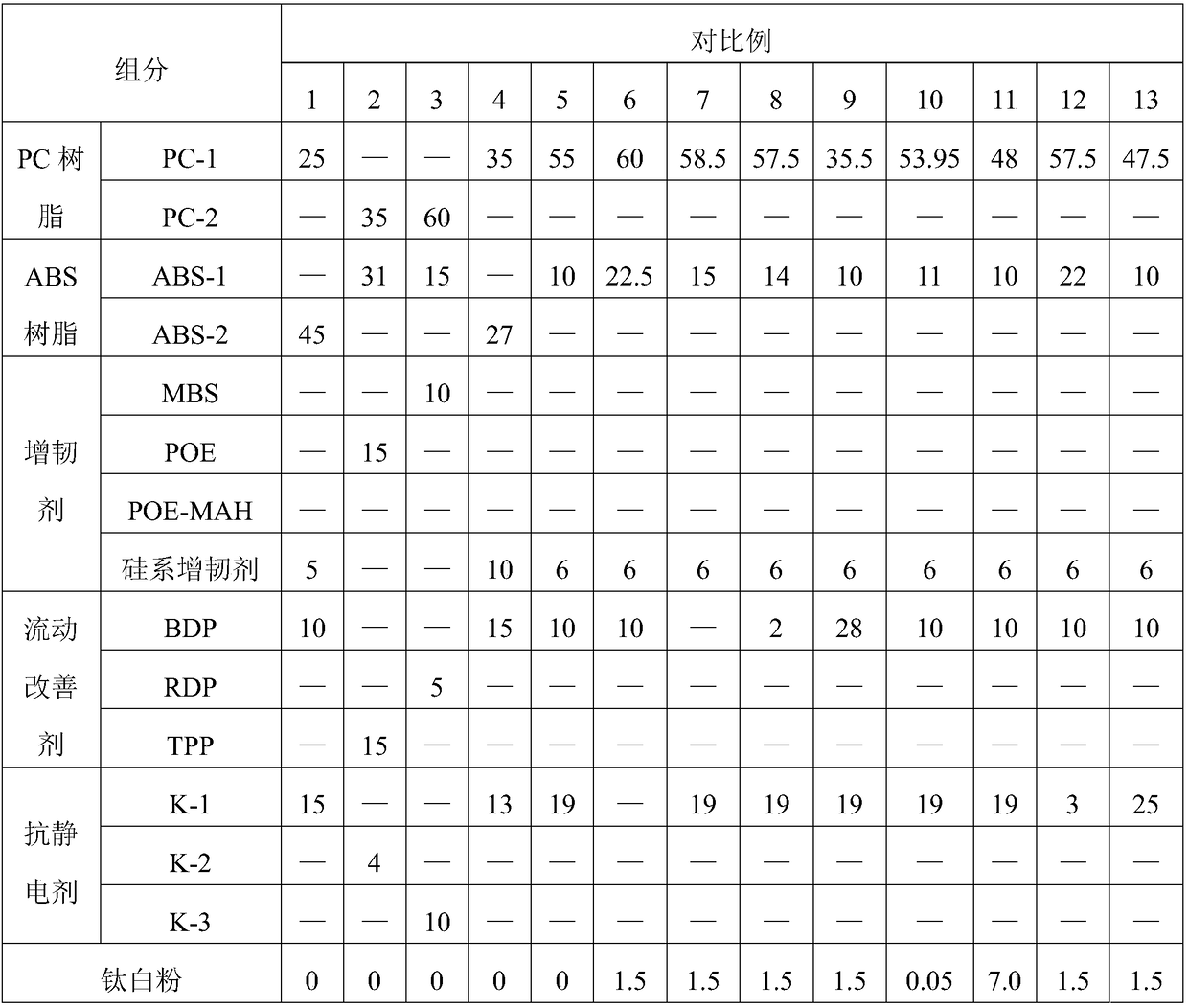

[0032] The PC / ABS composite materials of Comparative Examples 1-13 were prepared according to the formulations described in Table 2.

[0033] Table 2 comparative examples 1-13 each component consumption (unit: wt.%)

[0034]

[0035] The PC / ABS composite material prepared by above-mentioned specific examples and comparative examples is carried out notched impact strength test, melt index measurement and color fastness test, wherein notched impact strength test adopts Izod beam notched impact, and its test standard is ASTM D256, in Zwick Tested on an electronic universal testing machine; the test standard for the determination of the melt index is ISO-1133, the test condition is 260°C and 2.16KG, and the melt flow rate tester is used for testing; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com