Device and method for composite gas injection carbon reduction molten copper slag

A technology of composite gas and gas generating device, applied in the field of metallurgical process and equipment, can solve the problems of insufficient reduction, increased processing difficulty, low reduction efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

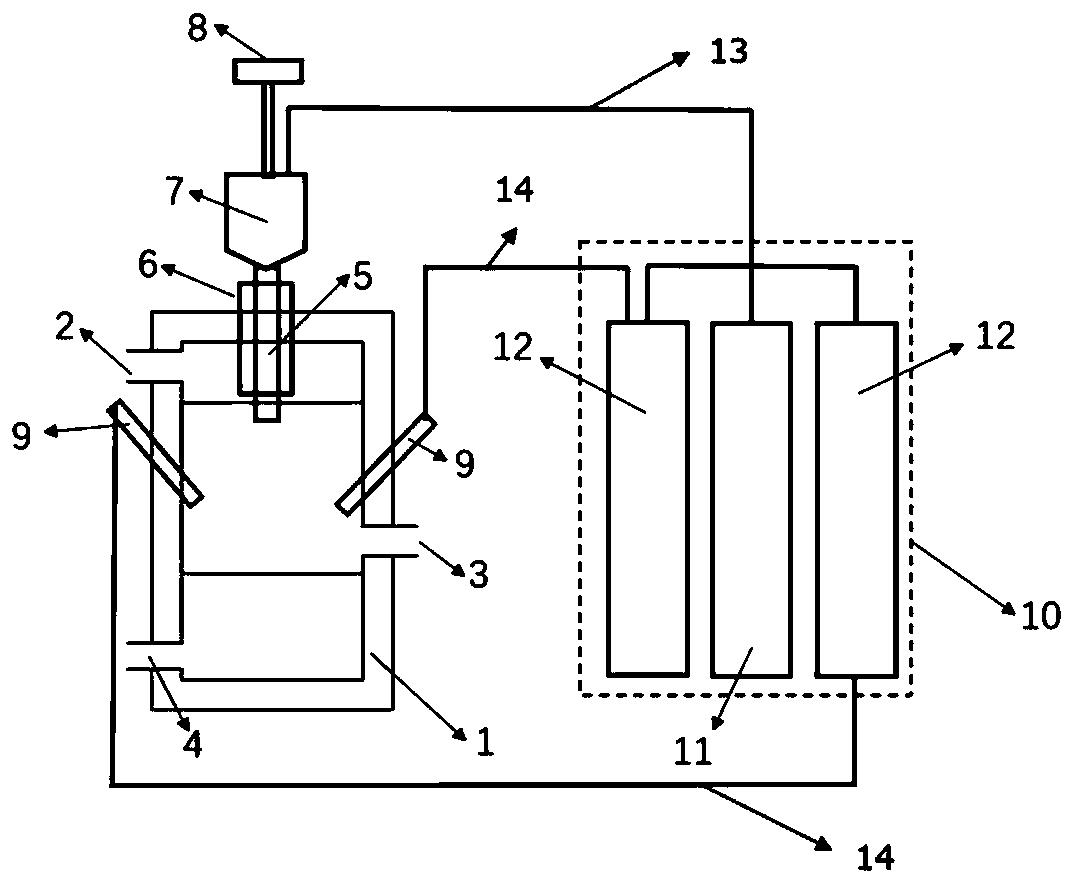

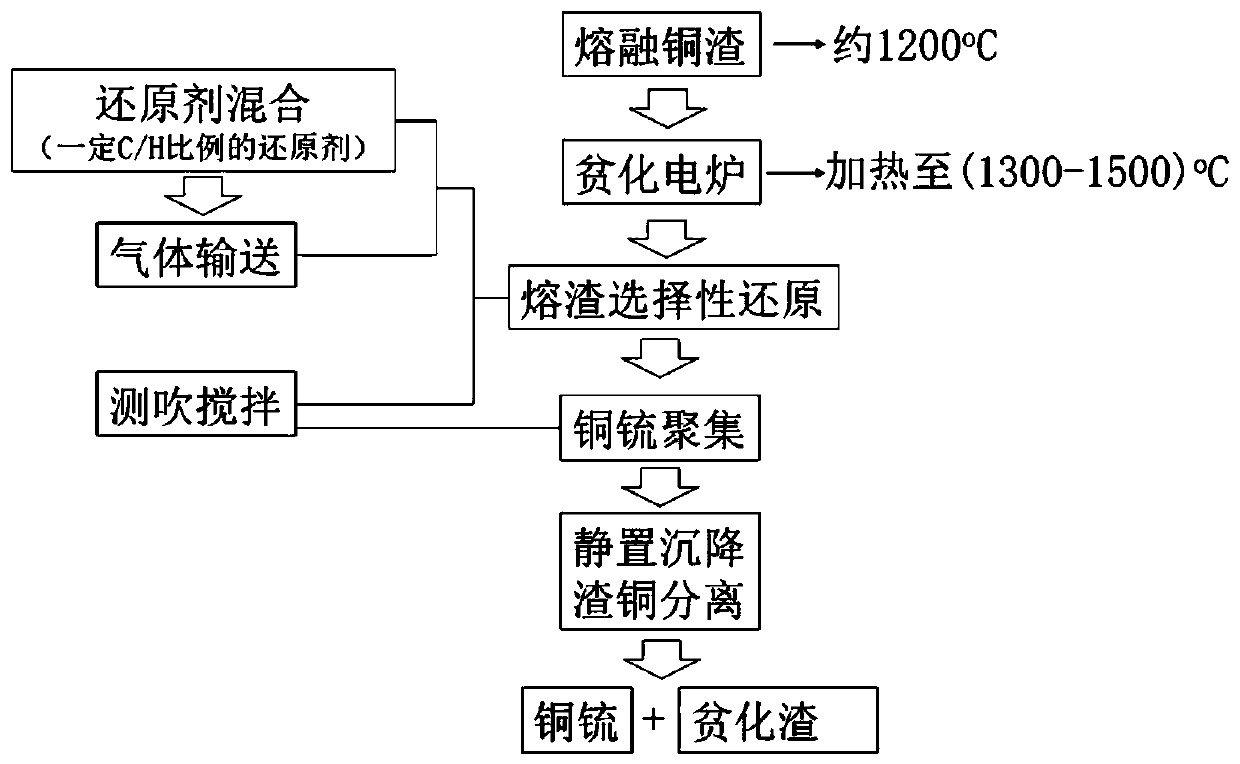

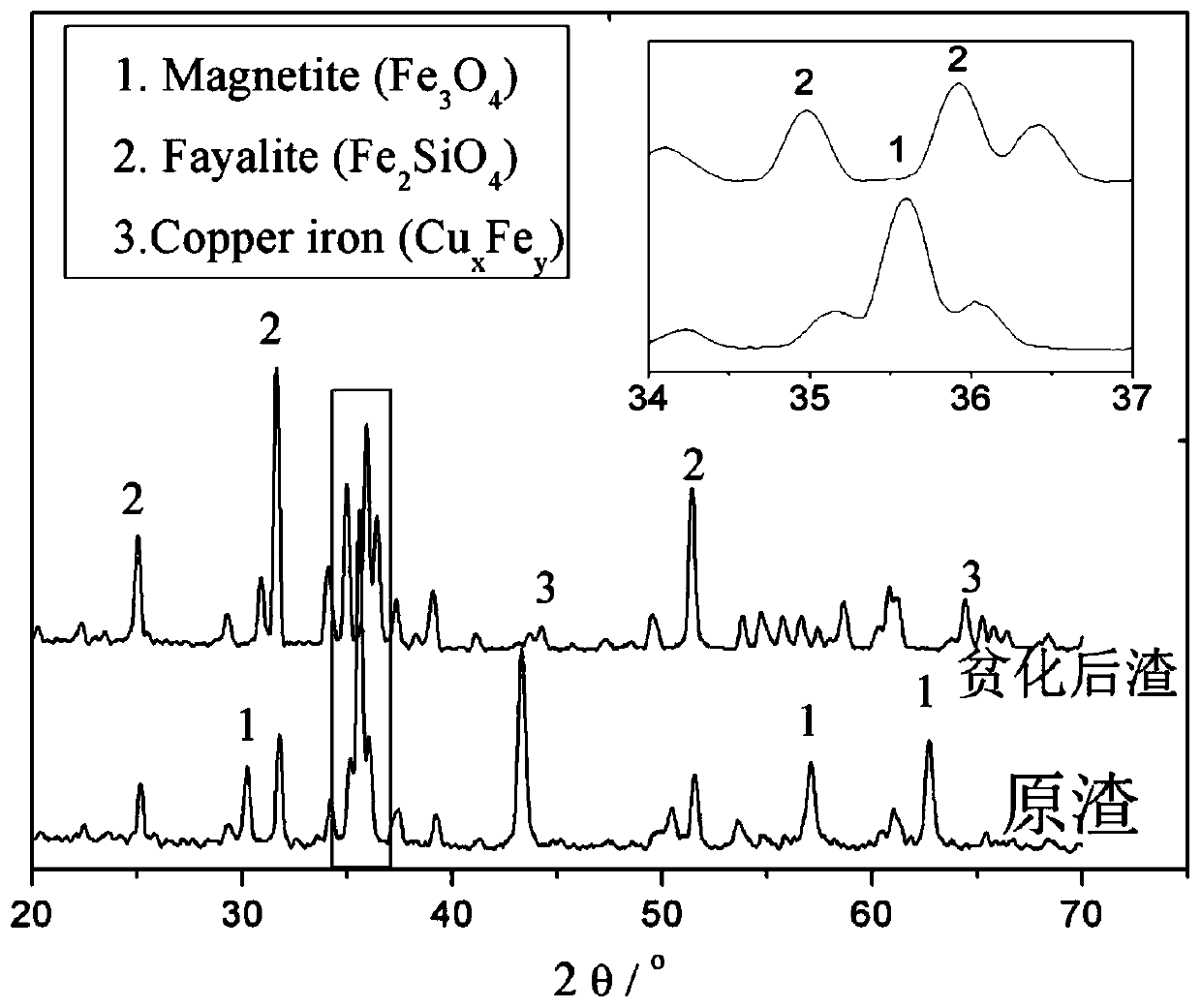

[0053] This embodiment is to selectively reduce the magnetite phase in the slag. The experimental process is a laboratory-scale experiment. During the depletion process, the electric resistance furnace is used to heat the depleted electric furnace. The reaction vessel is designed according to the patent requirements, and the slag processing capacity is about 5kg. This embodiment adopts figure 1 The device shown and figure 2 The process flow shown handles molten copper slag as follows:

[0054] Firstly, put the smelting slag into the electric resistance furnace and raise the temperature to 1400°C to make the slag have good fluidity; secondly, design the molar ratio of the top-blowing reducing agent to be 1:2 (actual reducing agent is CH 4 , flow rate 40L / min, pressure 0.2MPa), the inert gas for transportation is Ar gas, the flow rate is 40L / min, the pressure is 0.2MPa, the injection time is 30min, and the inert gas for side blowing and stirring is Ar gas, the flow rate is 40...

Embodiment 2

[0057] This example is for reduction preparation of copper-iron alloy. The experimental process is a scale-up test. In the depletion process, the electric furnace for heating the depletion is an induction furnace. The reaction vessel is designed according to the patent requirements, and the slag processing capacity is about 500kg. This embodiment adopts figure 1 The device shown and figure 2 The process flow shown handles molten copper slag as follows:

[0058] Firstly, put the smelting slag into the induction furnace and raise the temperature to 1500°C to make the slag have good fluidity; secondly, design the molar ratio of the top-blown reducing agent to be 1:4 (actual reducing agent is carbon powder and H 2 , H 2 The flow rate is 100Nm 3 / h, pressure 0.3MPa), the inert gas for transportation is Ar gas, and the flow rate is 100Nm 3 / h, the pressure is 0.3MPa, the injection time is 60min, and the inert gas used for side blowing and stirring is Ar gas, and the flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com