Residual alkali neutralizing device for mercerizing and operation technology of residual alkali neutralizing device

An operation process and residual alkali technology, which are applied in the field of mercerizing residual alkali neutralization device and its operation process, can solve the problems of unfavorable energy saving and emission reduction, low production efficiency, serious power consumption and water consumption, etc., so as to save water and electricity, improve efficiency, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

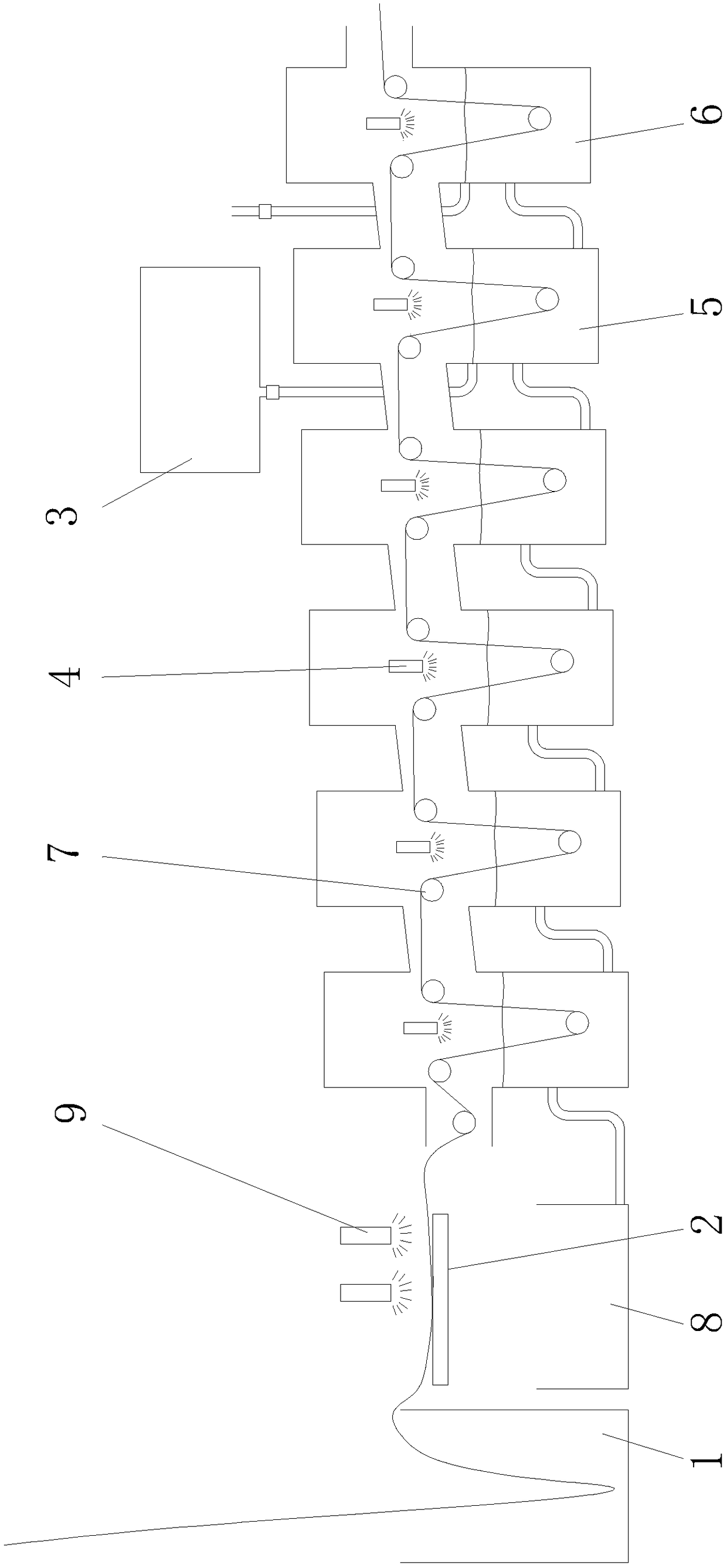

[0041] The first water tank to the sixth water tank are each equipped with a suction pump to extract the liquid in the water tank, and the suction pump is correspondingly connected to the spray device 4 in the water tank, and each water tank extracts the liquid from the water tank The liquid inside sprays the cloth.

Embodiment 2

[0043] The fifth water tank 5 is provided with a main suction pump for extracting the liquid in the water tank. The spray devices from the first water tank to the fifth water tank are connected through a common dry road, and the main road is connected with the main suction pump. That is, spray the cloth width passing through the first to fifth washing tanks with the liquid with higher concentration of medicinal solution in the fifth washing tank. The sixth washing tank 6 is provided with a clear water suction pump for extracting the liquid in the washing tank, and the clear water suction pump is connected to the spray device in the sixth washing tank.

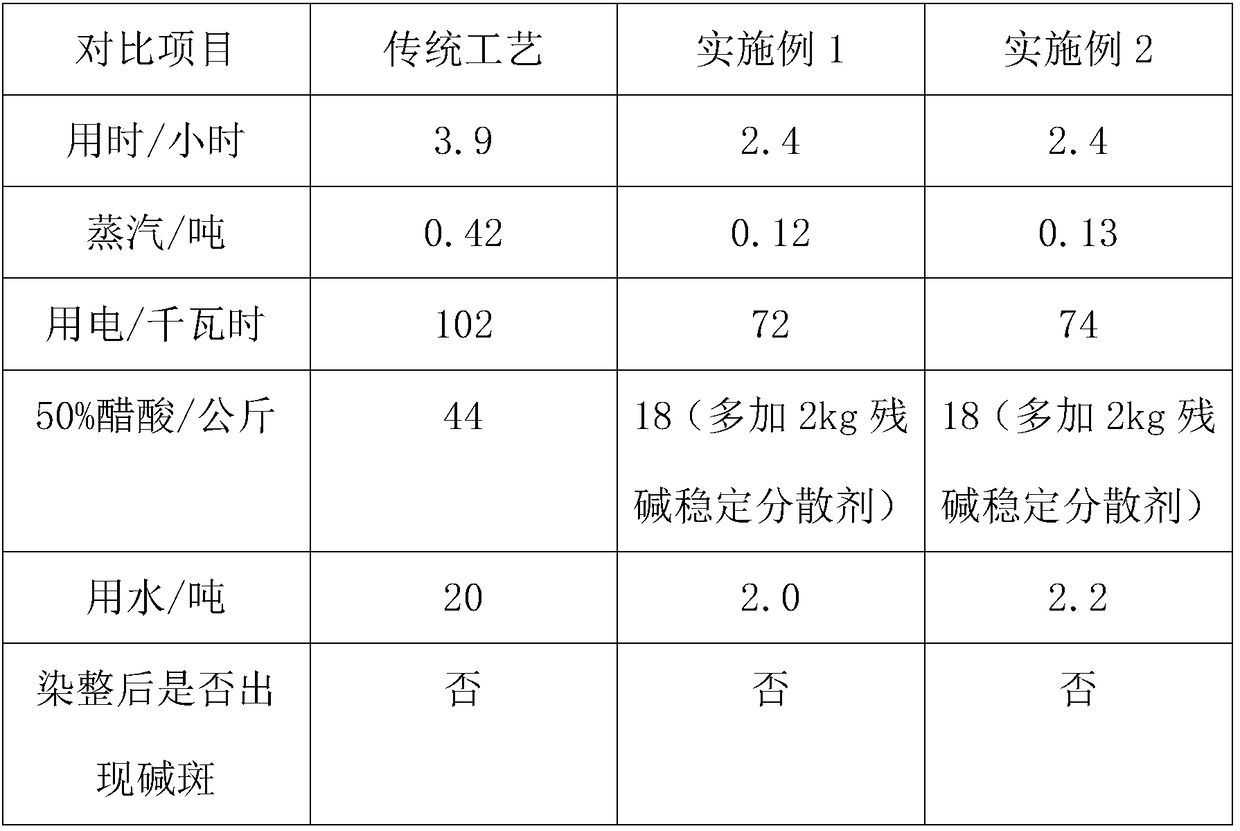

[0044]The above two examples were carried out in actual production respectively, and compared with the traditional process before technical transformation, the material consumption, energy consumption and production time were obtained in the following table. The data in the table is calculated by producing one ton of mercerized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com