Assembly type artificial fish reef

An artificial reef, prefabricated technology, applied in the field of civil engineering, can solve the problems of fish gathering effect and the improvement of the marine environment deviating from expectations, increasing the time of marine pastures, and increasing the recovery time of funds, etc., to solve the problems of ordinary reinforced concrete corrosion, Improve the formation of artificial fisheries and increase the effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

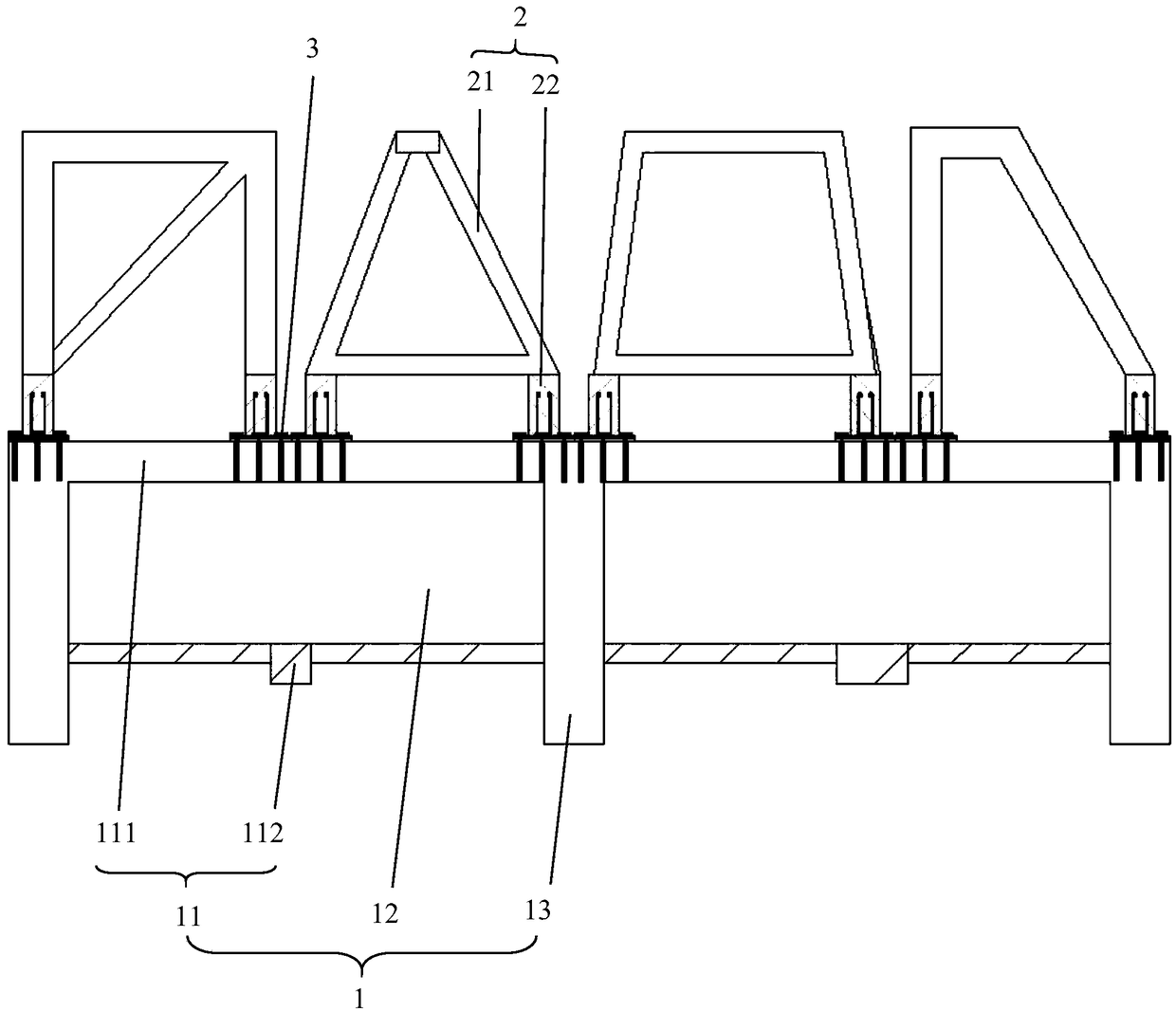

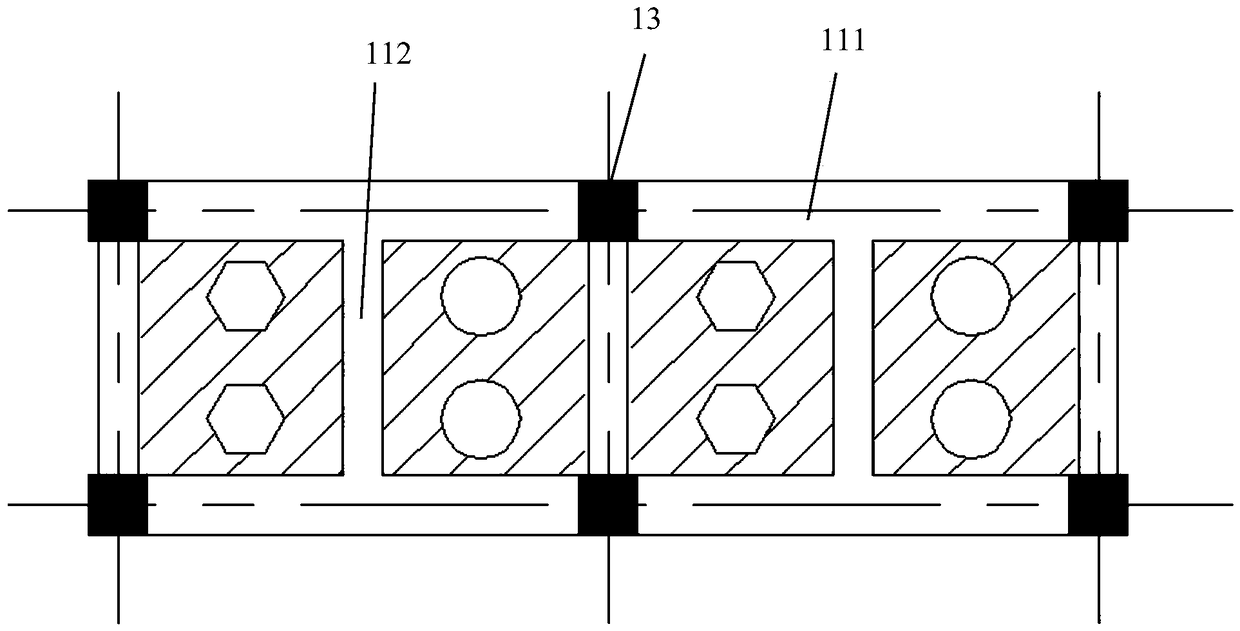

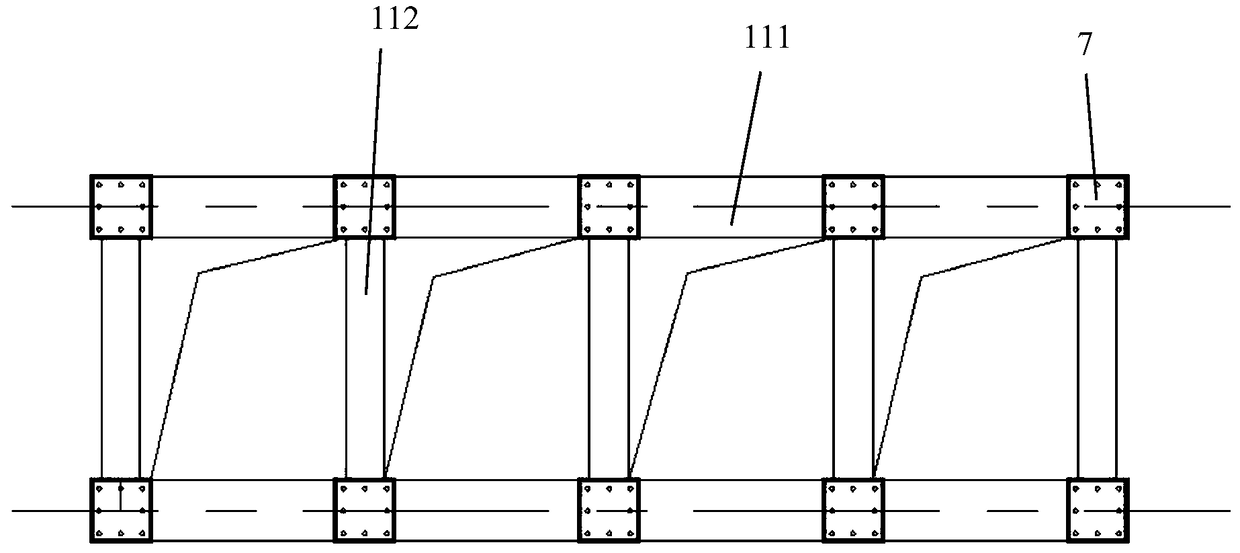

[0076] (1) Preparation of the foundation base: use FRP bars to bind the prefabricated beams, support the formwork, combine the bound prefabricated beams into a frame cage-shaped skeleton according to the formwork, pour fiber seawater and sea sand concrete, and then perform maintenance for standby;

[0077] (2) Preparation of assembly components: use FRP bars to bind the main frame, support the formwork, then pour fiber foam concrete and fiber seawater and sea sand concrete, and then perform maintenance for standby;

[0078] (3) Assembly of the artificial reef: transport the foundation base and assembly components to the place where the artificial fish reef is placed, install the assembly components on the base base through embedded parts, and fix them with screws to obtain a fabricated artificial reef.

[0079] In order to further optimize the above-mentioned technical solution, the interior of the foundation base described in step (1) is used for filling construction waste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com