Concrete cooling water pipe device

A technology for cooling water pipes and concrete, which is applied in construction, infrastructure engineering, etc. It can solve the problems of slowing down of the core temperature of concrete, achieve the effect of reducing costs and labor, and avoiding the cost of reversing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding and implementation of the present invention, the preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

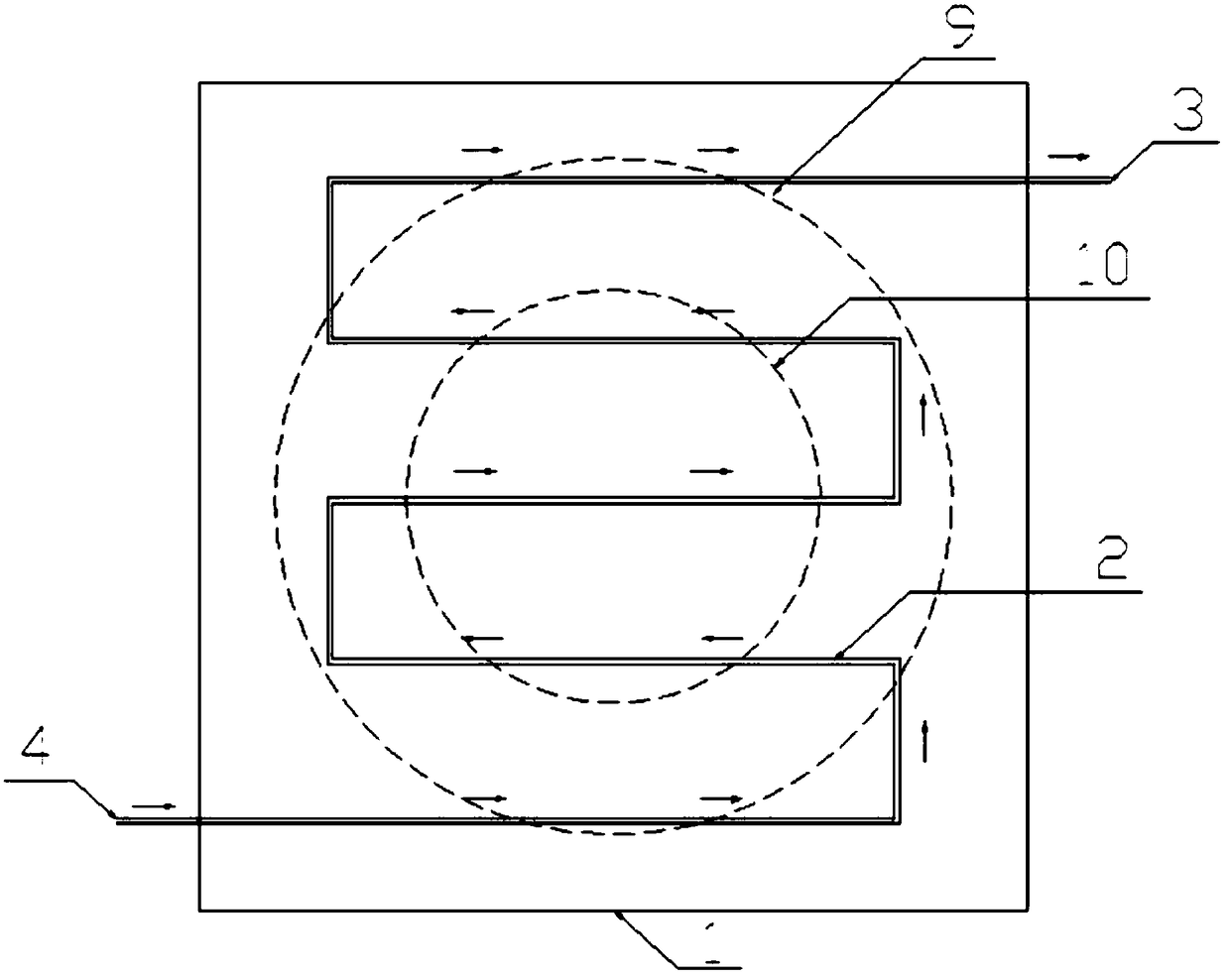

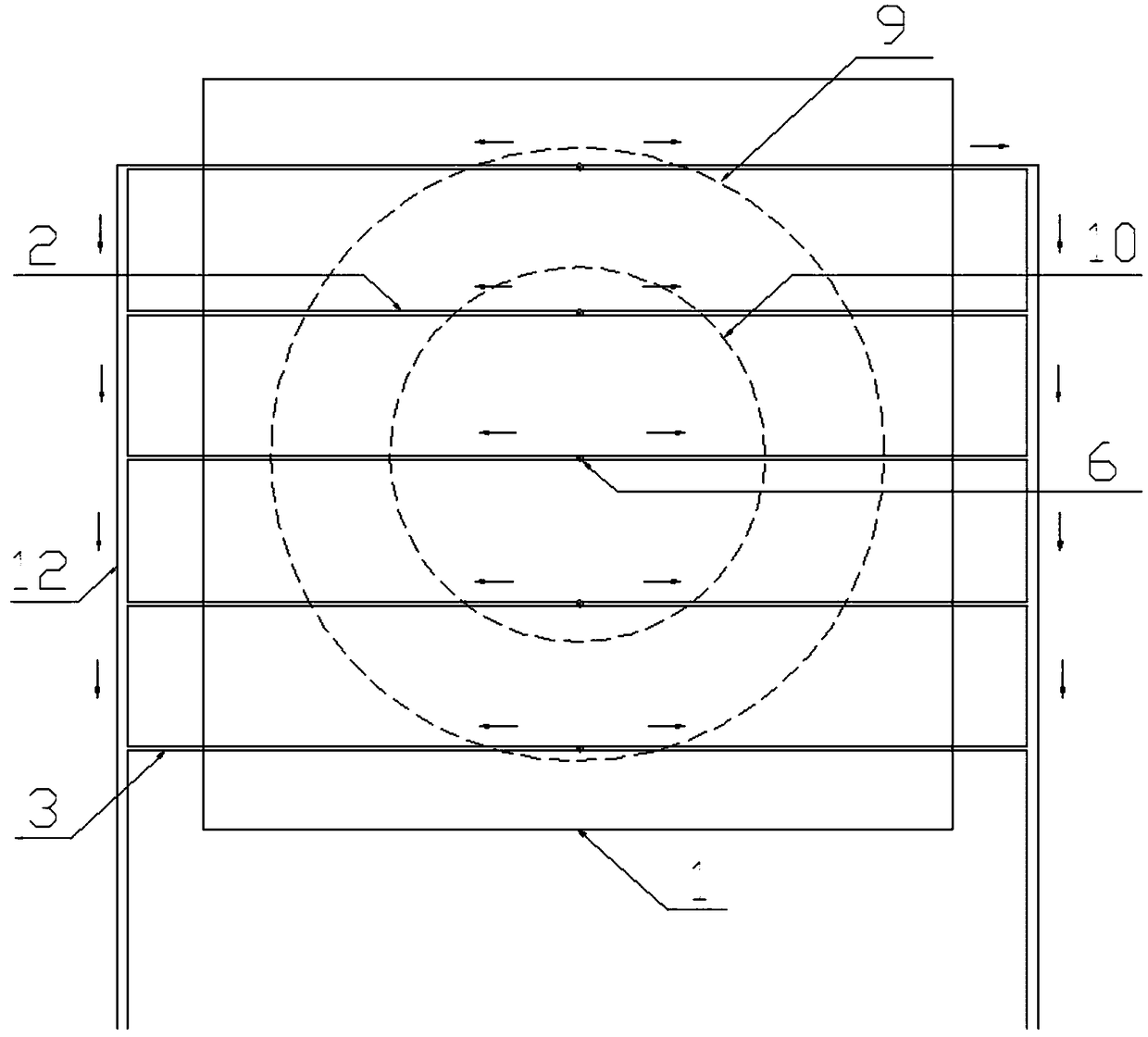

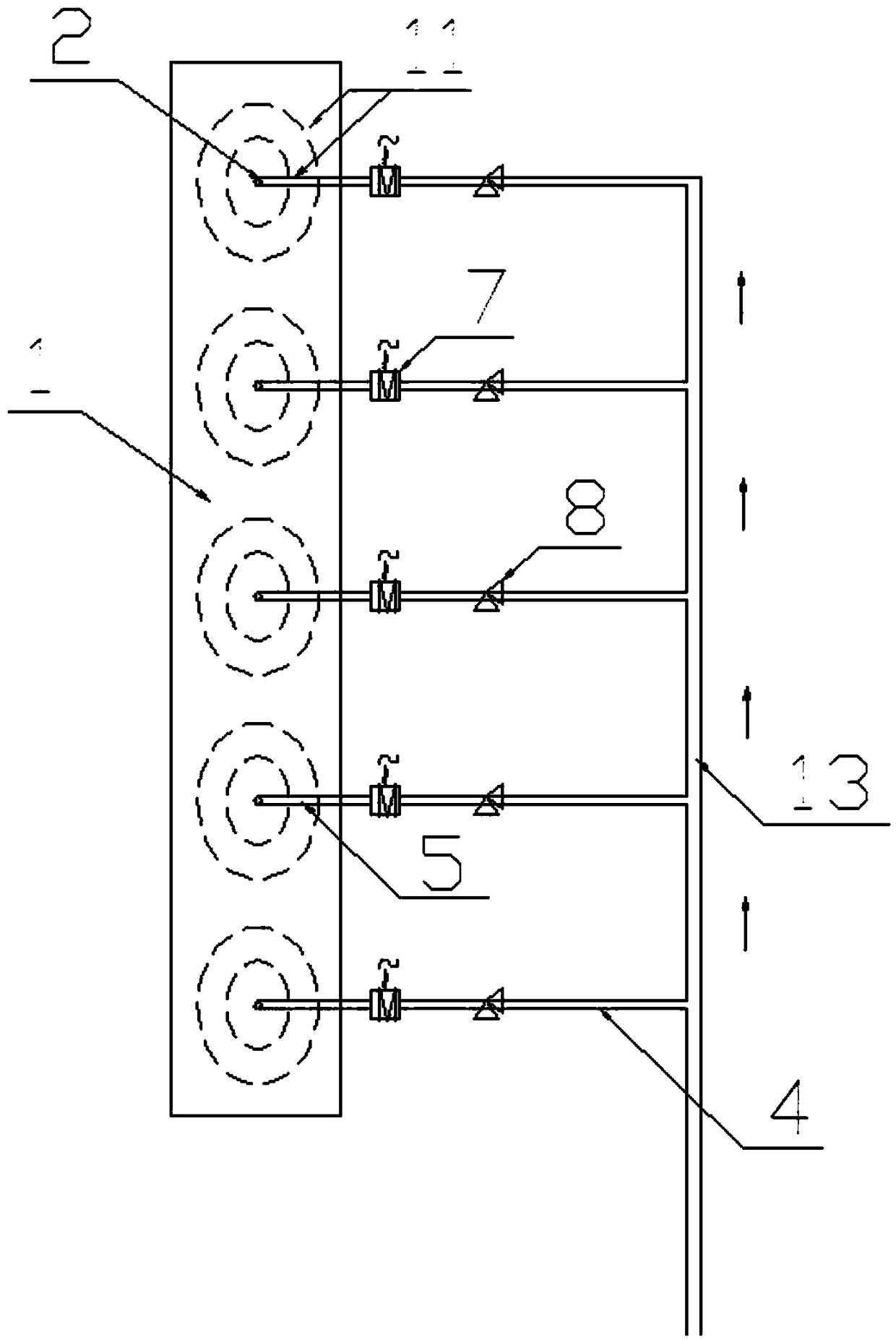

[0020] Such as Figure 2 to Figure 4 As shown, the present invention includes concrete 1 and cooling water pipes 2 arranged in the concrete 1, the cooling water pipes 2 are arranged at the center of the thickness direction of the concrete 1, the thickness of the concrete 1 is less than or equal to 1.5m, and the cooling water pipes 2 are evenly spaced in the concrete 1. Each cooling water pipe 2 protrudes from the end faces of both sides of the concrete 1 and connects with the outlet pipe 3 at the end face; the middle position of each cooling water pipe 2 is respectively connected to the water inlet pipe 4 through the connecting pipe 5, and the water inlet pipe 4 is in the The middle part of the outer surface of the concrete 1 is in contact with the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com