Non-disassembling engine dynamic fuel injection advance angle detection method

A technology of fuel injection advance angle and detection method, which is applied in the detection of dynamic fuel injection advance angle without disassembly of the engine fuel injection system, and in the field of engine dynamic fuel injection advance angle detection based on oil pipe vibration signals, which can solve the problem of not being able to realize non-disintegration measurement, It is not suitable for real vehicle inspection of the engine, and cannot reflect the fuel injection advance angle and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

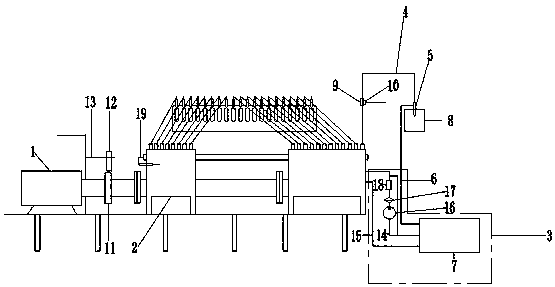

[0018] The invention is described in conjunction with accompanying drawings and specific embodiments:

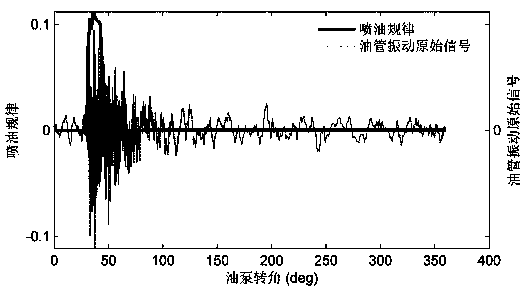

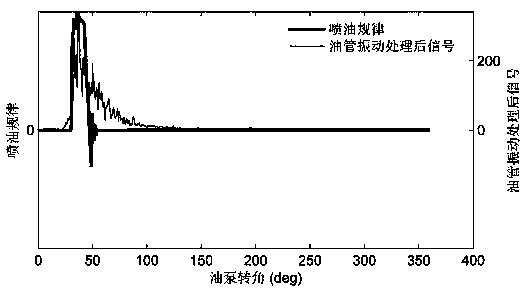

[0019] combine Figure 4 , a non-disintegrating engine dynamic fuel injection advance angle detection method, first on the fuel injection pump test bench, the fuel injection pump-high-pressure fuel pipe-fuel injector system to be tested is tested for fuel injection rules, and at the same time, the high-pressure fuel pipe is subjected to dynamic vibration testing; Then, by processing the vibration signal of the high-pressure fuel pipe, and using the measured fuel injection law to calibrate the vibration signal, the corresponding relationship between the vibration signal and the fuel injection advance angle is obtained; After the corresponding relationship of the advance angle, the vibration signal of the high-pressure oil pipe in the real vehicle state can be dynamically detected, so as to realize the dynamic fuel injection advance angle detection in the real vehicle state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com