A kind of preparation method of aluminum-plastic film for lithium ion battery

A lithium-ion battery and aluminum-plastic film technology, applied in the field of aluminum-plastic film, can solve the problems of low electrolyte resistance, weak resistance, and many resin crystal points, and achieve the production conditions of avoiding high temperature and high pressure, and electrolyte resistance Excellent performance and maintain the appearance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

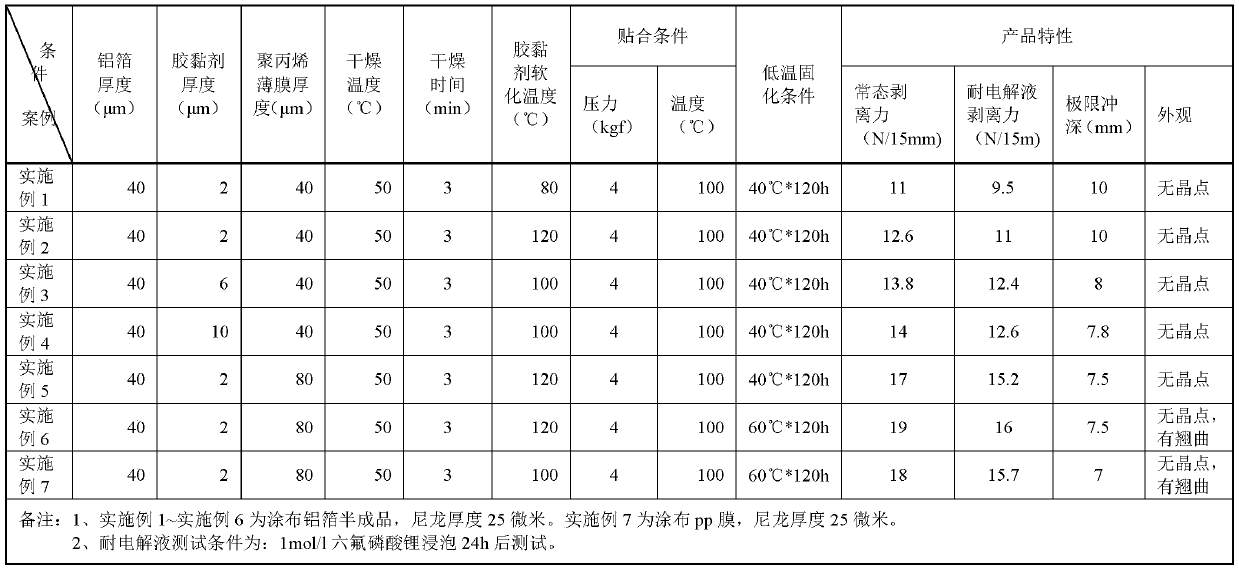

Examples

Embodiment

[0022] A method for preparing an aluminum-plastic film for a lithium-ion battery. The specific process is as follows: firstly, the resin polypropylene used for preparing the aluminum-plastic film by a thermal method is grafted and modified to obtain a modified chlorinated polypropylene (MCPP); It becomes an adhesive for dry coating, and the solvent used for dissolving can be methylcyclohexane, toluene, xylene, alicyclic hydrocarbons (such as n-hexane, etc.); first coat the adhesive on an aluminum film or Modified chlorinated polypropylene film, dry to evaporate the solvent in the adhesive coating; then apply the other side of the adhesive to the Modified chlorinated polypropylene film bonding; and vice versa) heat the adhesive coating to 80-120°C by heating rollers or other heating devices, so that the adhesive layer can be softened and have sufficient viscosity and fluidity , to meet the needs of bonding, after bonding, after a period of low-temperature curing, the adhesive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com