Dry compounding process of composite aluminum-plastic film used for power battery

A technology of power battery and dry compounding, which is applied in the direction of chemical instruments and methods, lamination auxiliary operation, lamination, etc., can solve the problems of poor weather resistance, lithium intolerance, easy moisture absorption, etc., and achieve excellent mechanical properties and low production cost. The effect of low and low temperature environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

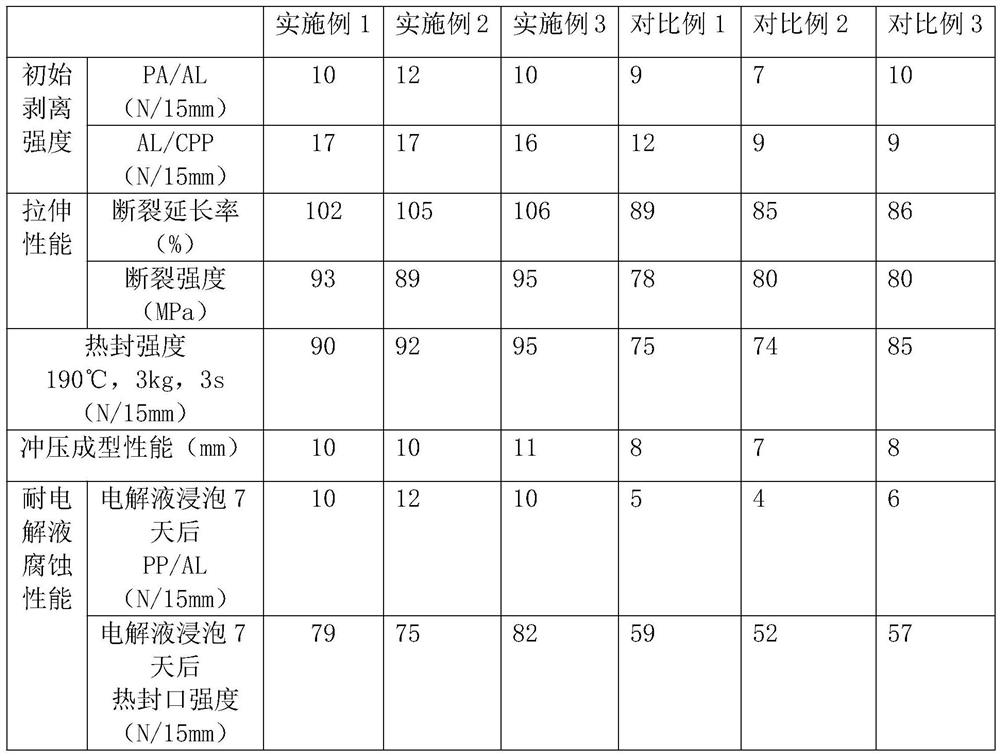

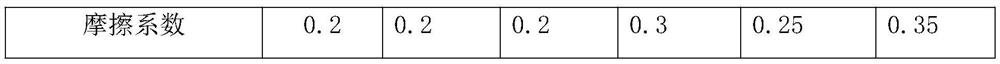

Examples

Embodiment 1

[0033] A dry composite process for a composite aluminum-plastic film for a power battery, comprising the following steps:

[0034] (1) Aluminum foil pretreatment: treat the grease attached to the surface of the aluminum foil, and apply 12g / m on the aluminum foil 2 The coating amount is evenly coated with modified polyurethane glue, and then dried in three temperature ranges of 75°C, 85°C, and 100°C to obtain pretreated aluminum foil; the modified polyurethane glue is made of polyester / ether polyol, carbon Prepared by dissolving nanotubes, polyisocyanate and additives in ethyl acetate at a mass ratio of 15:3:3:2.5;

[0035] (2) Dry compounding of nylon and aluminum foil: the nylon after corona treatment and the pretreated aluminum foil are dry compounded by a compounding machine at 75-80°C, so that the nylon is compounded on the aluminum foil, cured and formed, Winding after cooling to obtain nylon / aluminum foil composite film;

[0036] (3) Curing of nylon / aluminum foil compo...

Embodiment 2

[0042] A dry composite process for a composite aluminum-plastic film for a power battery, comprising the following steps:

[0043] (1) Aluminum foil pretreatment: treat the grease attached to the surface of the aluminum foil, and use 8g / m2 on the aluminum foil 2 The coating amount is evenly coated with modified polyurethane glue, and then dried in three temperature ranges of 75°C, 85°C, and 100°C to obtain pretreated aluminum foil; the modified polyurethane glue is made of polyester / ether polyol, carbon Prepared by dissolving nanotubes, polyisocyanate and additives in ethyl acetate at a mass ratio of 20:4:4:4;

[0044] (2) Dry compounding of nylon and aluminum foil: the nylon after corona treatment and the pretreated aluminum foil are dry compounded by a compounding machine at 75-80°C, so that the nylon is compounded on the aluminum foil, cured and formed, Winding after cooling to obtain nylon / aluminum foil composite film;

[0045] (3) Curing of nylon / aluminum foil composite...

Embodiment 3

[0051] A dry composite process for a composite aluminum-plastic film for a power battery, comprising the following steps:

[0052] (1) Aluminum foil pretreatment: treat the grease attached to the surface of the aluminum foil, and use 5g / m2 on the aluminum foil 2 The coating amount is evenly coated with modified polyurethane glue, and then dried in three temperature ranges of 75°C, 85°C, and 100°C to obtain pretreated aluminum foil; the modified polyurethane glue is made of polyester / ether polyol, carbon Prepared by dissolving nanotubes, polyisocyanate and additives in ethyl acetate at a mass ratio of 25:5:5:6;

[0053] (2) Dry compounding of nylon and aluminum foil: the nylon after corona treatment and the pretreated aluminum foil are dry compounded by a compounding machine at 75-80°C, so that the nylon is compounded on the aluminum foil, cured and formed, Winding after cooling to obtain nylon / aluminum foil composite film;

[0054] (3) Curing of nylon / aluminum foil composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com