Motor-independent cooling loop system and manufacturing method

A cooling circuit, independent technology, used in cooling/ventilation devices, manufacturing motor generators, electrical components, etc., can solve the problems of large combined cooling circuit system, slow application development, complex structure design, etc., to achieve universal Good compatibility and interchangeability, simple structure design, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

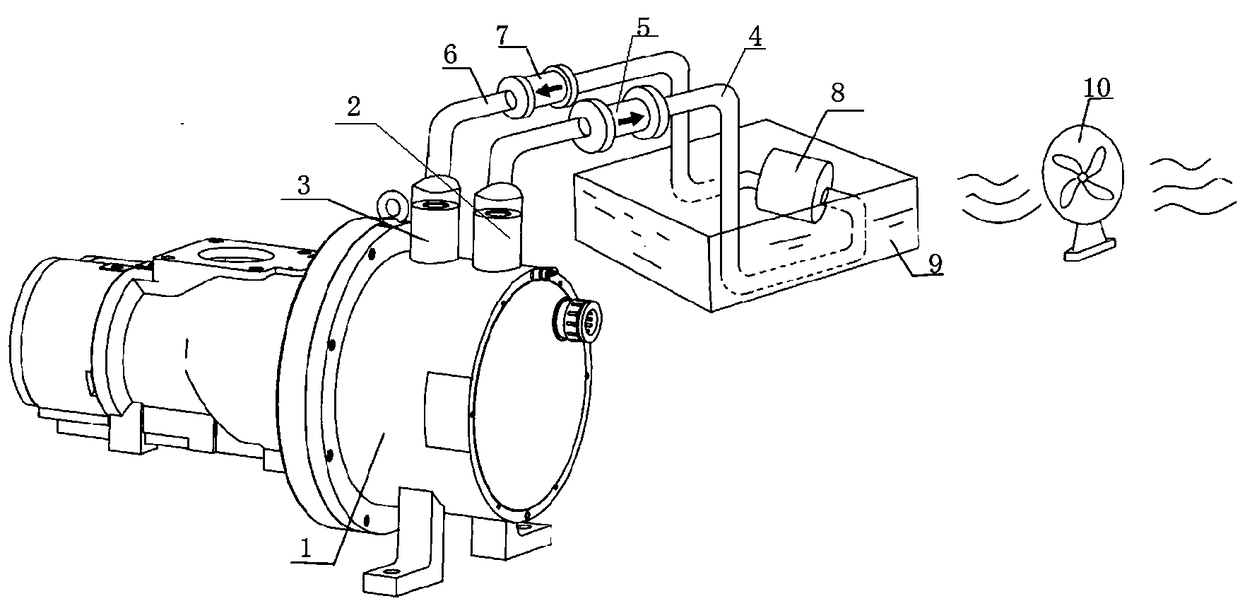

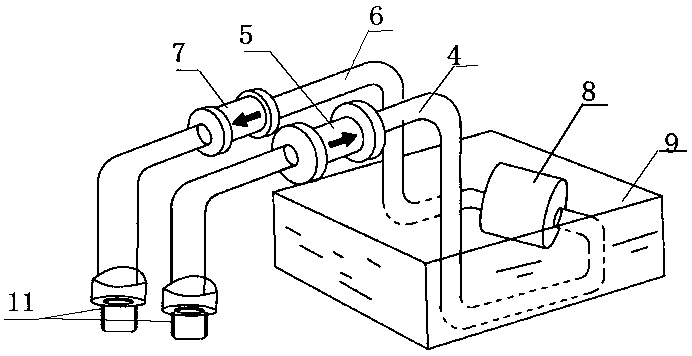

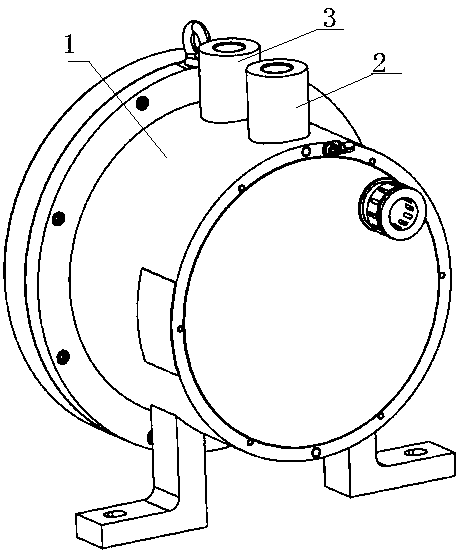

[0034] The following is based on Figure 1 to Figure 10 The specific embodiment of the present invention is further described:

[0035] see figure 1 , a motor independent cooling circuit system, including a servo motor and a cooling circuit system, the interior of the motor housing 1 of the servo motor is provided with a plurality of cooling channels 12 arranged along the radial direction of the motor housing 1, The head end of the cooling channel 12 is connected with an oil inlet 3 , and the end is connected with an oil outlet 2 . The cooling circuit system includes: a first cooling pipeline 6, a second cooling pipeline 4, a first one-way valve 7, a second one-way valve 5, a cooling medium storage tank 8, a cooling water tank 9 and a fan 10, and the cooling medium storage tank One end of 8 communicates with the oil inlet 3 of the motor housing 1 through the first cooling pipeline 6 and the first check valve 7 is installed on the first cooling pipeline 6, and the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com