Three-level high-voltage high-power water-cooled frequency converter system

A high-power, frequency converter technology, applied in the field of electrical control structural components, can solve the problems that the space utilization of the excitation winding system occupies a large space, poor heat dissipation performance affects the service life of the thyristor, and damages the performance and service life of the frequency converter. Increase the function of dual system switching, improve the effect of RC absorption, and improve the effect of power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

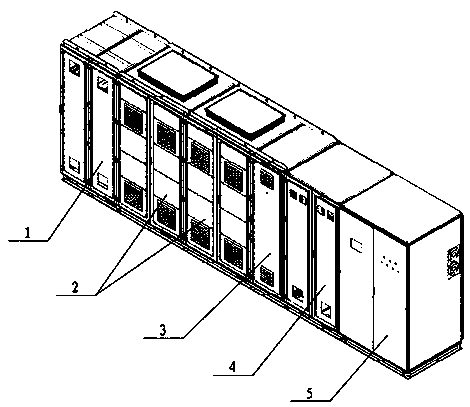

[0030] Example 1: see figure 1 , a three-level high-voltage high-power water-cooled inverter system, including: water-cooled filter cabinet 1, expandable bridge arm parallel inverter cabinet 2, all-digital regulation cabinet 3, water-cooled excitation winding system cabinet 4, water circulation cooling system cabinet 5; The water-cooled filter cabinet 1, the expandable bridge arm parallel inverter cabinet 2, the full digital regulation cabinet 3, the water-cooled excitation winding system cabinet 4, and the water circulation cooling system cabinet 5 are assembled and combined with each other from left to right to form a set A more complete high-voltage and high-power water-cooled inverter system.

Embodiment 2

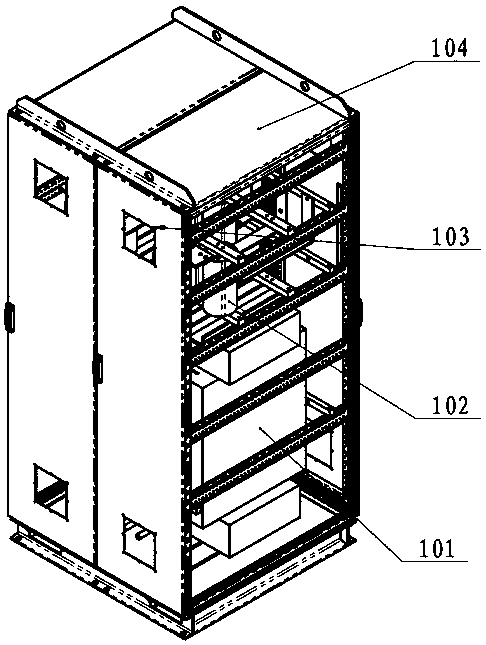

[0031] Example 2: see figure 2 , as an improvement of the present invention, the water-cooled filter cabinet 1 includes a high-voltage high-power water-cooled reactor 101, a circulating reactor module 102, a spoiler fan 103, and a filter cabinet composition 104; the high-voltage high-power water-cooled The reactor 101 is installed on the lower side of the filter cabinet 104, and is fixed on the channel steel base of the filter cabinet by bolts; the circulating reactor module 102 is installed on the top of the high-voltage and high-power water-cooled reactor 1, through the screw, After the insulating support is clamped and fixed, it is fixed on the left and right fixed beams of the filter cabinet with bolts; the spoiler fan 103 is installed on the upper part of the filter cabinet 104 door, preferably behind the supporting filter group; The power water-cooled reactor 101, the circulating reactor module 102, and the spoiler fan 103 are fixedly installed in corresponding position...

Embodiment 3

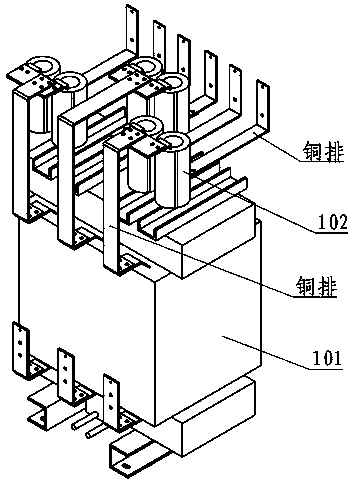

[0032] Embodiment 3: see Figure 2-4 , as an improvement of the present invention, the high-voltage high-power water-cooled reactor 101 suppresses surge voltage and surge current, protects the frequency converter, prolongs its service life and prevents harmonic interference, improves the power factor of the frequency converter and suppresses Harmonic current, filtering out harmonic voltage and harmonic current, can not only prevent the interference from the power grid, but also reduce the pollution of the harmonic current generated by the rectifier unit to the power grid; adopt a new type of water and electricity separation, foil winding process reactor, Further solves the heat dissipation problem caused by the high-power reactor, and cooperates with the "double-arm power unit-based inverter" water-cooled heat dissipation system to improve the overall space utilization; the high-voltage high-power water-cooled reactor 101 is installed in the filter cabinet body 104 inner under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com