Fermenting making technology of gynura procumbens fermented tea

The invention relates to a technology for recumbent chrysanthemum Panax notoginseng and a production process, which is applied in the field of tea production, and can solve the problems of waste, single function of food, short storage time, etc., and achieve the effects of improving storage period, quality and production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

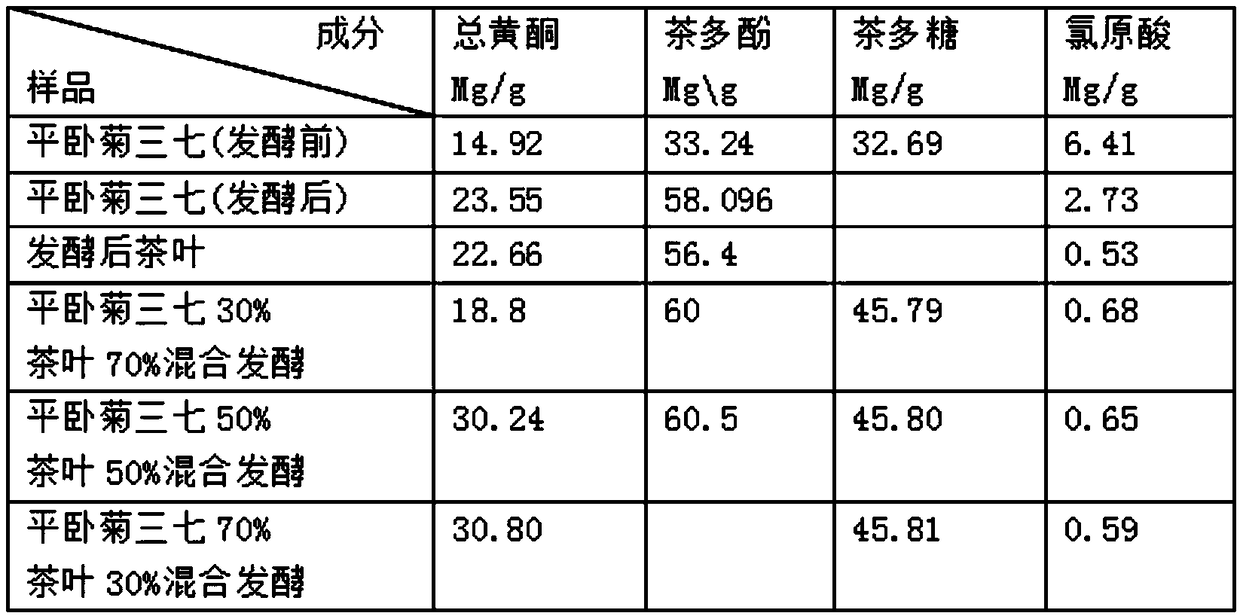

Examples

Embodiment 1

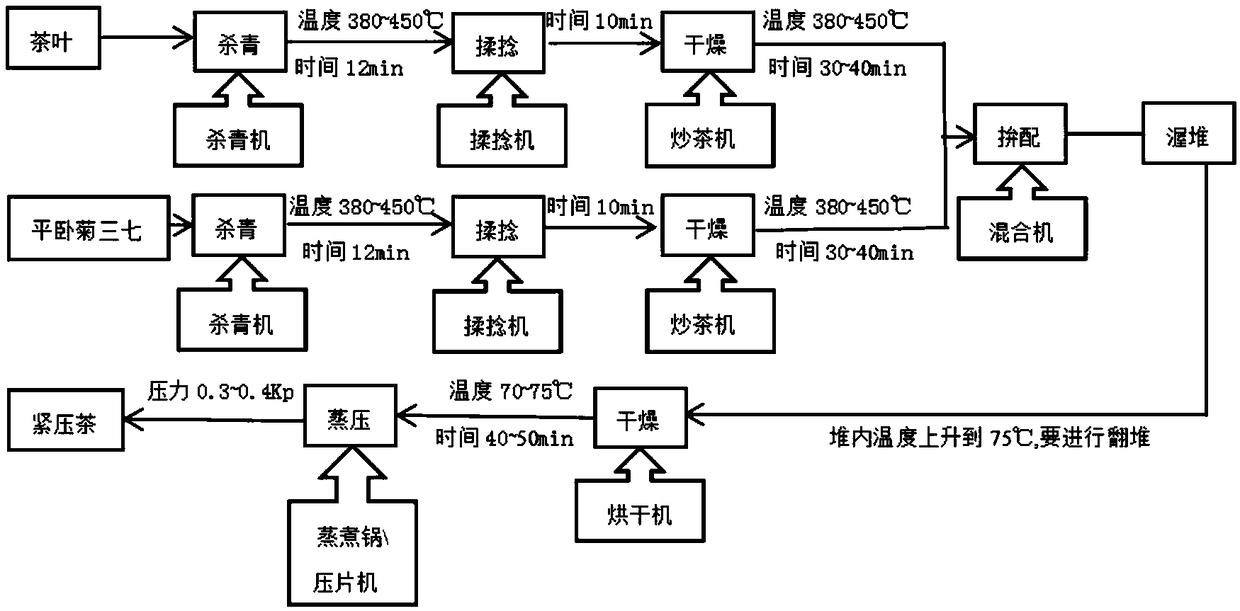

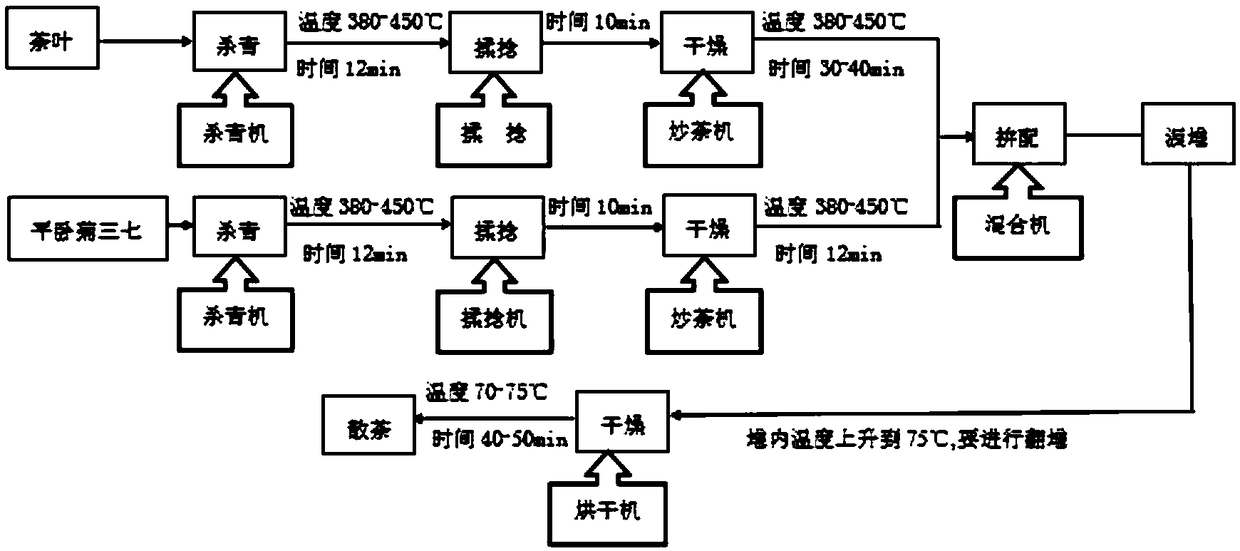

[0041] see figure 1 , the fermentation production process of flat lying chrysanthemum notoginseng fermented tea, including the following processes:

[0042] S1: select fresh and tender tea leaves, remove the stems, select fresh flat lying chrysanthemum notoginseng;

[0043] S2: Carry out de-enzyming, kneading and first drying of tea leaves and chrysanthemum panax notoginseng respectively. It takes 12 minutes to create conditions for kneading and shaping, and the moisture content of the tea leaves is kept at 30-35%;

[0044] a2, kneading, put the finished tea leaves into a kneading machine, knead the leaves, roll them into strips, and reduce the volume for 10 minutes;

[0045] a3. For the first drying, move the twirled tea leaves to the tea frying machine, and evaporate part of the internal moisture at a high temperature of 380-450°C to create conditions for fermenting. The time is 30-40min, and the moisture in the tea leaves is kept at 15-20 %;

[0046] b1. Finishing, put ...

Embodiment 2

[0054] see figure 1 , the fermentation production process of flat lying chrysanthemum notoginseng fermented tea, including the following processes:

[0055] S1: select fresh and tender tea leaves, remove the stems, select fresh flat lying chrysanthemum notoginseng;

[0056] S2: Carry out de-enzyming, kneading and first drying of tea leaves and chrysanthemum panax notoginseng respectively. It takes 12 minutes to create conditions for kneading and shaping, and the moisture content of the tea leaves is kept at 30-35%;

[0057] a2, kneading, put the finished tea leaves into a kneading machine, knead the leaves, roll them into strips, and reduce the volume for 10 minutes;

[0058] a3. For the first drying, move the twirled tea leaves to the tea frying machine, and evaporate part of the internal moisture at a high temperature of 380-450°C to create conditions for fermenting. The time is 30-40min, and the moisture in the tea leaves is kept at 15-20 %;

[0059] b1. Finishing, put ...

Embodiment 3

[0067] see figure 1 , the fermentation production process of flat lying chrysanthemum notoginseng fermented tea, including the following processes:

[0068] S1: select fresh and tender tea leaves, remove the stems, select fresh flat lying chrysanthemum notoginseng;

[0069] S2: Carry out de-enzyming, kneading and first drying of tea leaves and chrysanthemum panax notoginseng respectively. It takes 12 minutes to create conditions for kneading and shaping, and the moisture content of the tea leaves is kept at 30-35%;

[0070] a2, kneading, put the finished tea leaves into a kneading machine, knead the leaves, roll them into strips, and reduce the volume for 10 minutes;

[0071] a3. For the first drying, move the twirled tea leaves to the tea frying machine, and evaporate part of the internal moisture at a high temperature of 380-450°C to create conditions for fermenting. The time is 30-40min, and the moisture in the tea leaves is kept at 15-20 %;

[0072] b1. Finishing, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com