Non-damage garlic splitting device capable of imitating shape of garlics

A non-injury, garlic technology, applied in applications, food processing, food science, etc., can solve the problems of easily damaged garlic cloves, complexity, and large volume, and achieve the effects of easy use, simple structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

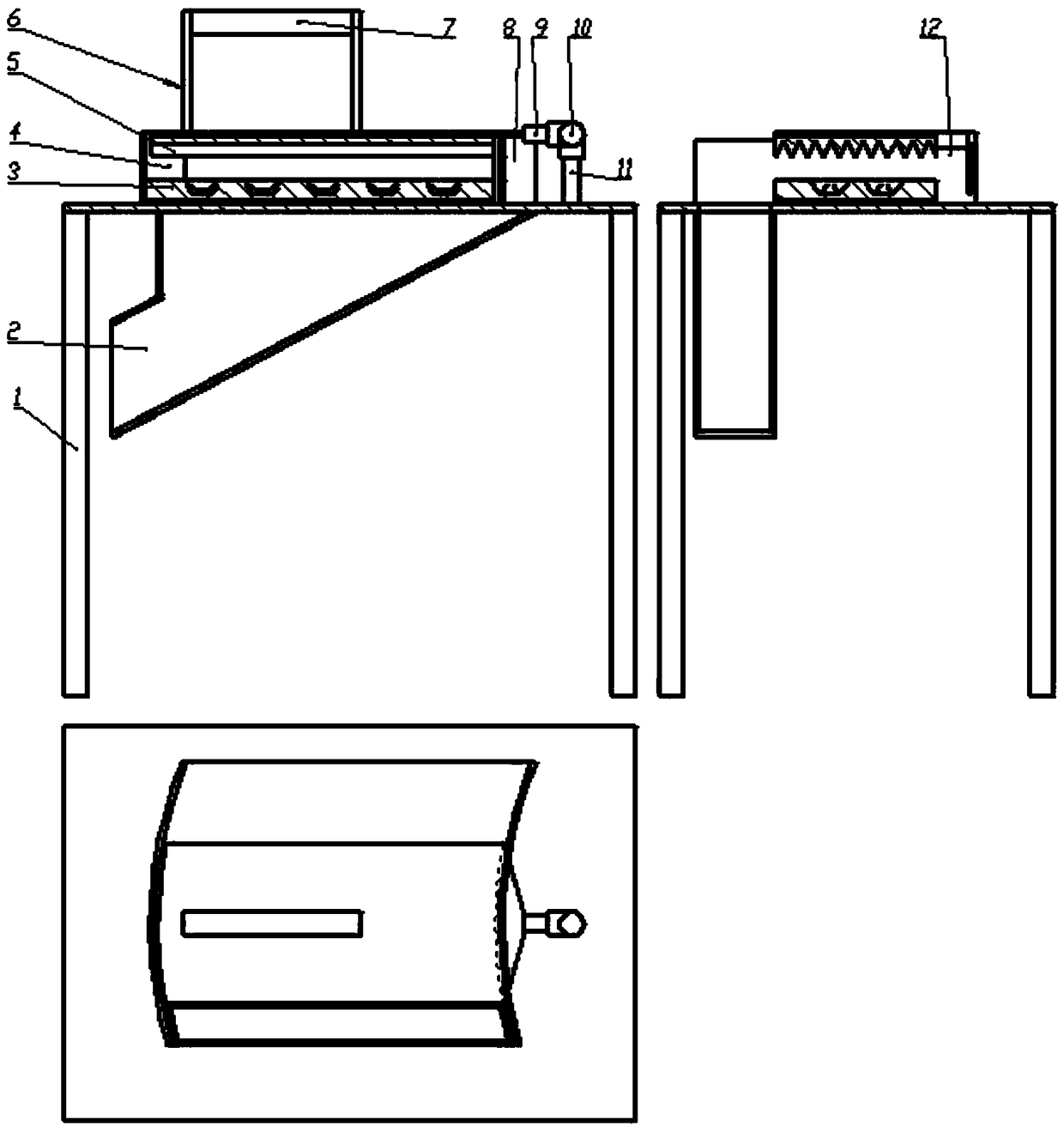

[0033] Such as figure 1 As shown, a garlic-like non-damaging garlic splitting device includes: workbench 1, funnel collection device 2, positioning device 3, baffle A4, kneading and pressing device 5, support 6, handle 7, baffle B8, rotating Shaft 9, universal joint 10, vertical shaft 11 and brush scraper collection device 12.

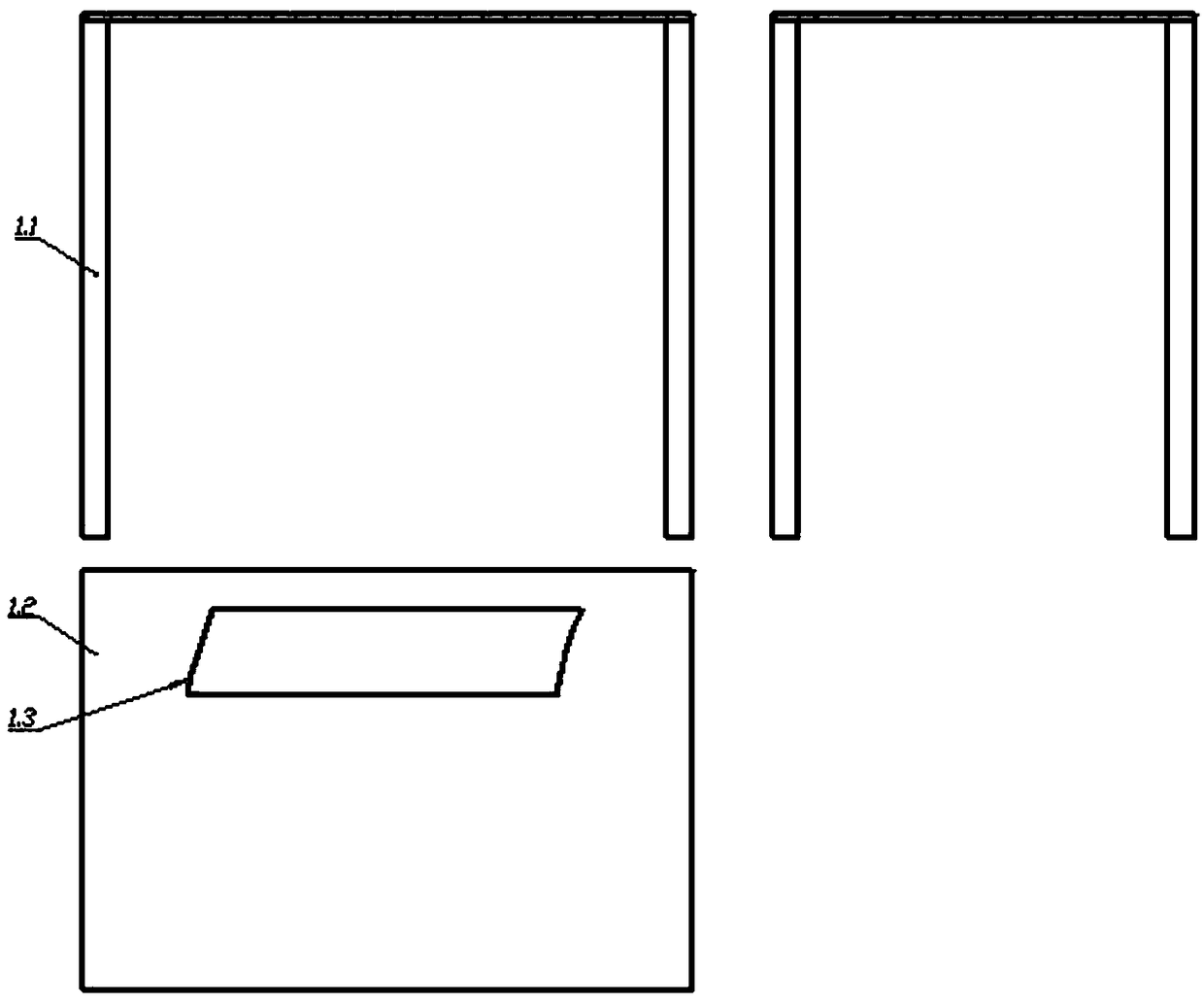

[0034] Such as figure 2 As shown, the workbench 1 includes: a column 1.1, a table top 1.2 and a collection port 1.3. The table top 1.2 is a rectangular plate made of a steel plate with a thickness of 5-10mm; the table top 1.2 is 500-1000mm long and 400-600mm wide; each of the four corners below the table top 1.2 is welded with a vertical column 1.1. Column 1.1 is made of rectangular steel with a height of 500-1000mm. A transparent collection port 1.3 is processed on the table panel 1.2. The front and rear opposite sides of the collection port 1.3 are straight sides, the length of the straight side is 200-400 mm, and the distance between the two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com