Advanced oxidation hydrolysis-waste gas purifying device

A waste gas purification device, advanced oxidation technology, applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy corrosion, high cost, short retention time, etc., to achieve strong adaptability and automation. High, simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

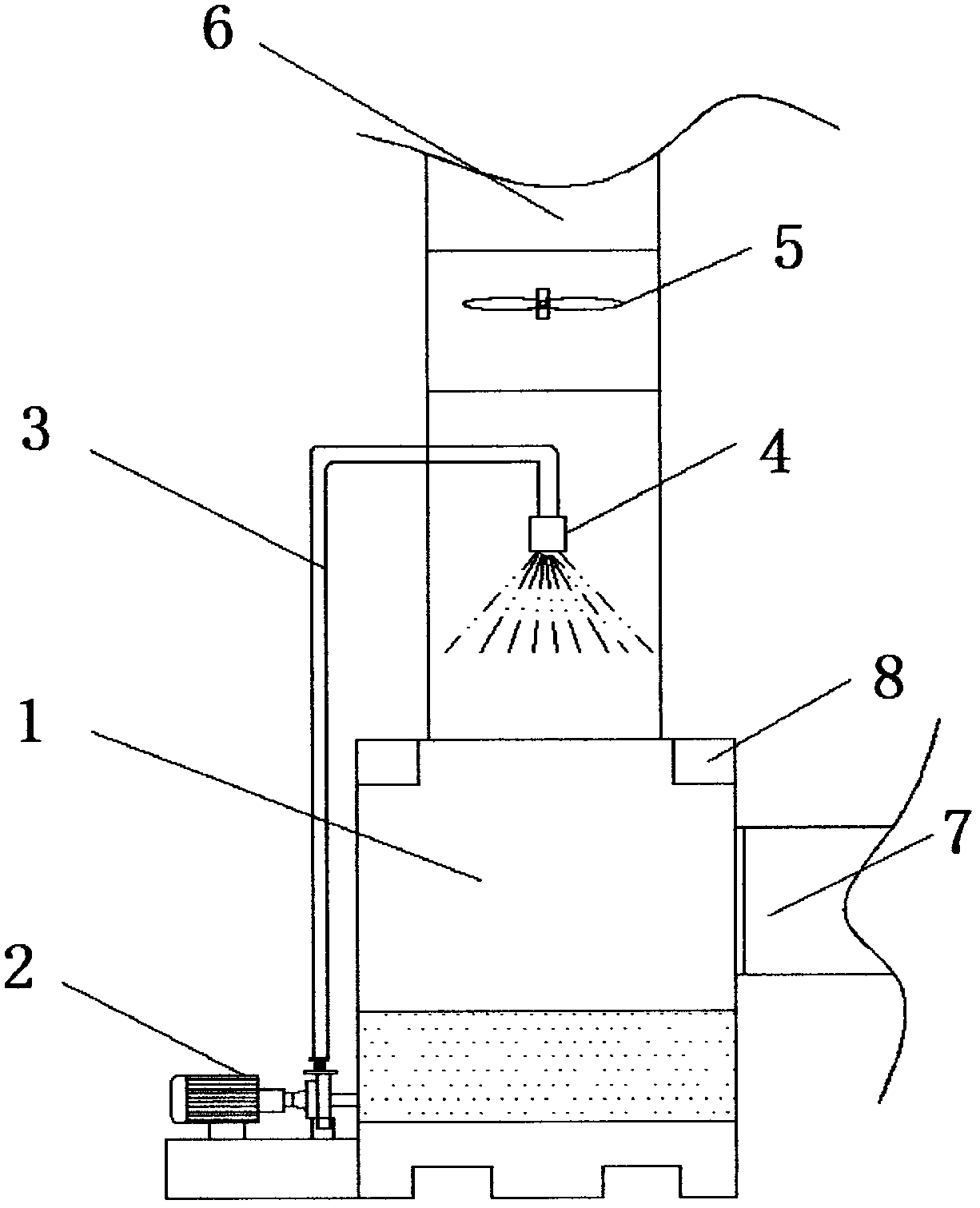

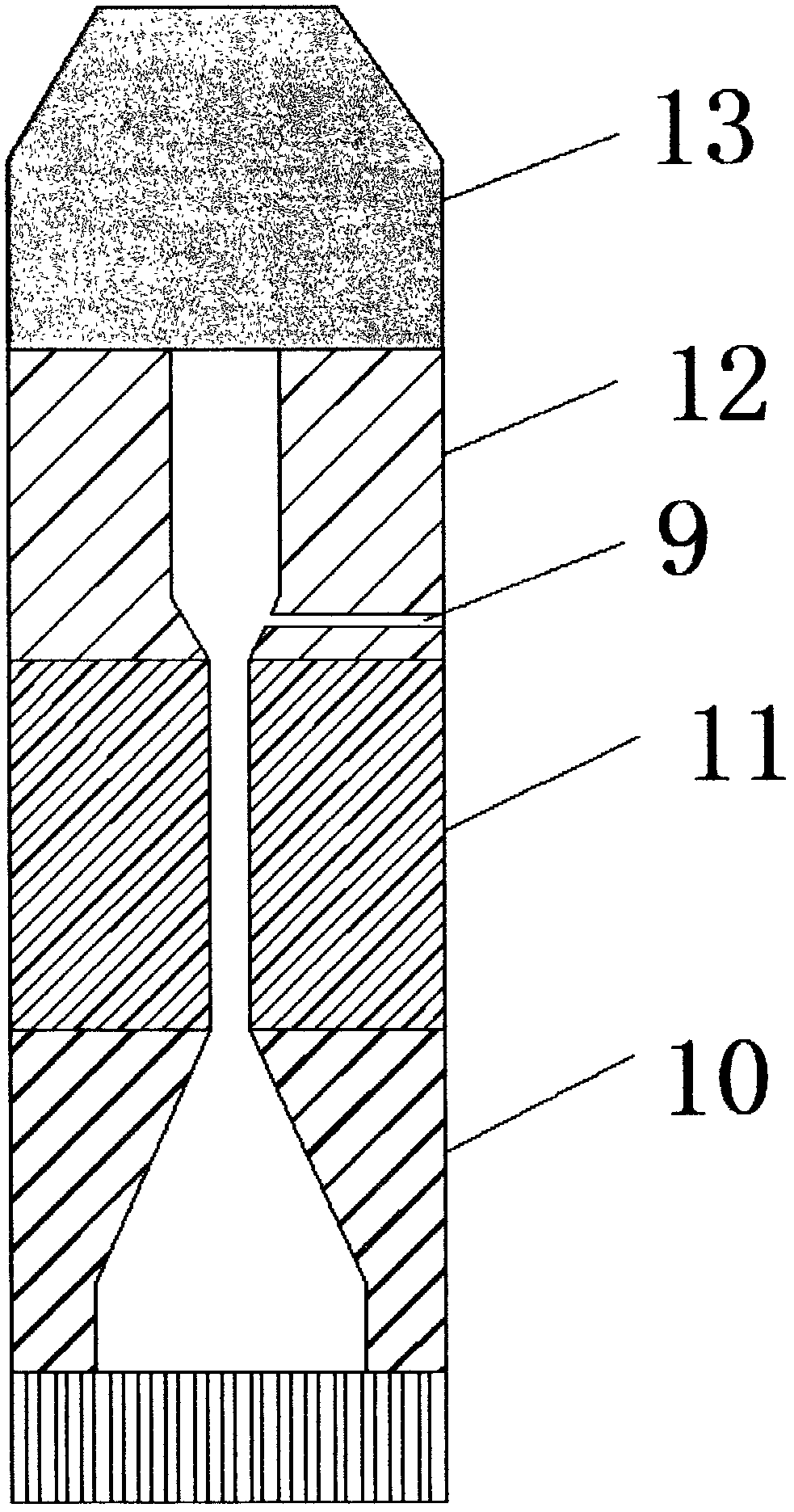

[0025] refer to Figure 1-3 , an advanced oxidation hydrolysis-exhaust gas purification device, including a body 1, a water tank is provided at the bottom of the body 1, a circulating water pump 2 is installed on one side of the bottom of the body 1, an air inlet 7 is provided on the other side of the bottom of the body 1, and the body 1 is Cavity structure, the body 1 includes a hydroxyl generator 8, a special nozzle 4, a mixed flow fan 5 and an air outlet 6, which are sequentially arranged from bottom to top. The hydroxyl generator 8 can be used alone or in combination. The circulating water pump 2 There is a spray pipe 3 connected to the special nozzle 4, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com