Spraying technology of cabinet-wood

A technology for wood and furniture, applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of damage to the topcoat layer and poor durability, and achieve a product that is not easy to be exposed, has good durability, and has a high degree of aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

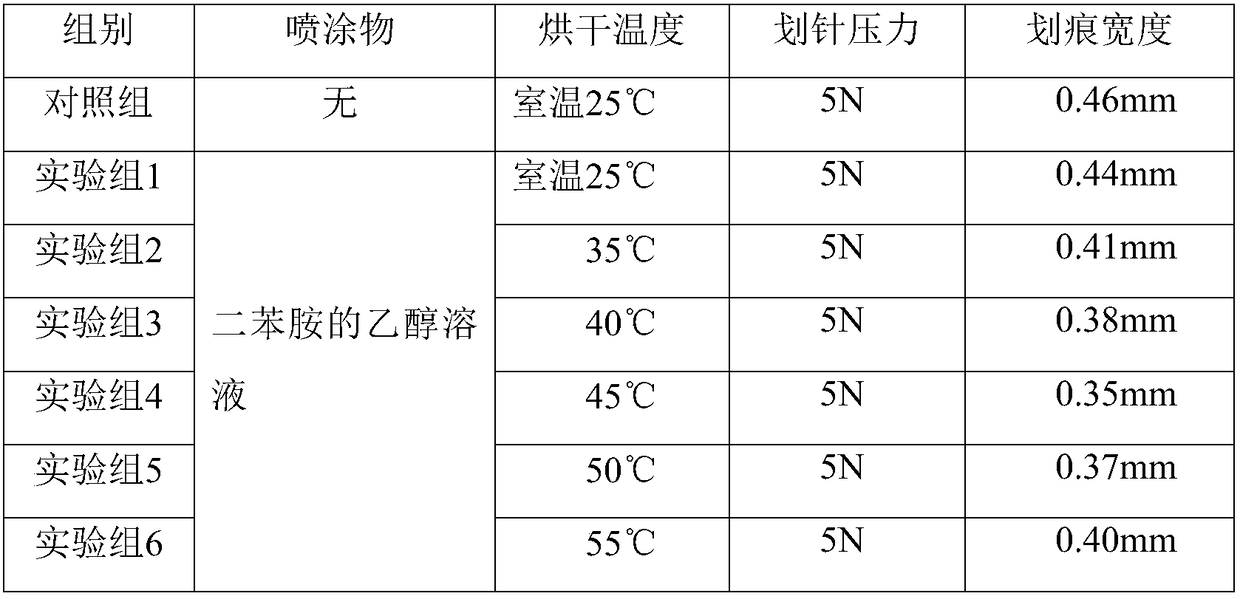

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below.

[0032] The invention discloses a spraying process for furniture wood, which comprises the following steps:

[0033] Step S1: pretreatment process, including step S11 to step S17:

[0034] Step S11: Take the cut plank and smooth the surface.

[0035] Step S12: Spray the anti-explosion agent on the surface of the panel. The explosion-proof agent has strong penetration and wetting ability, and can form a uniform thin layer on the surface of the board, which greatly reduces the surface tension of the paint liquid, greatly improves the wettability of the paint liquid and the surface of the board, and then improves the paint layer. Saturation makes the paint layer more vivid and full, improving the aesthetics. After the explosion-proof agent is sprayed, it needs to stand still for 6-7 hours before proceeding to the next process, because the explosion-proof agent can effectively fill the wooden holes of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com