Low-temperature-resistant shock-resistant automobile bumper material

An automobile bumper and impact-resistant technology, which is applied in the field of composite materials, can solve the problems of not meeting the requirements of bumpers, low impact resistance, poor low temperature resistance, etc., to achieve inhibition of photo-oxidation process, strong impact resistance, and flow good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

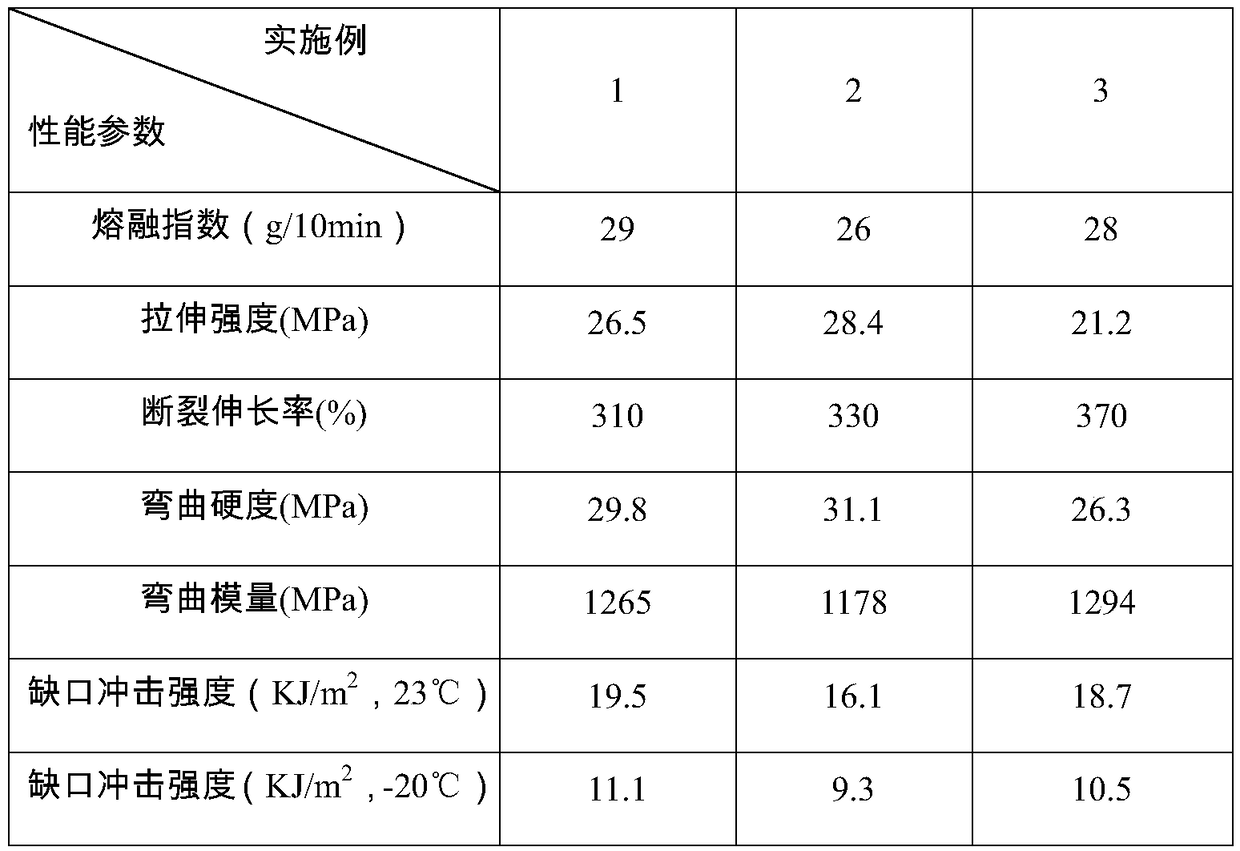

Examples

Embodiment 1

[0026] A low-temperature-resistant and impact-resistant automobile bumper material, comprising the following components in parts by mass: 40 parts of polypropylene, 15 parts of ethylene-propylene rubber, 12 parts of thermoplastic elastomer, 12 parts of talcum powder 0, 6 parts of carbon nanotubes, 4 parts 1 part compatibilizer, 2 parts light stabilizer, 2 parts coupling agent, 1 part lubricant, 1 part antioxidant, 1 part dispersant.

[0027] The polypropylene is a copolymerized polypropylene with a melt flow rate of 200-1000 g / 10 min.

[0028] The grade of the thermoplastic elastomer is G155D.

[0029] The compatibilizer is a maleic anhydride grafted compatibilizer.

[0030] The light stabilizer is a combination of hindered amine light stabilizer, ultraviolet absorber UV-P, and ultraviolet absorber UV-O.

[0031] The coupling agent is aminopropyltriethoxysilane.

[0032] The lubricant is paraffin oil.

[0033] The antioxidant is 2,6-tertiary butyl-4-methylphenol, bis(3,5-t...

Embodiment 2

[0039] A low-temperature-resistant and impact-resistant automobile bumper material includes the following components in parts by mass: 50 parts of polypropylene, 10 parts of ethylene-propylene rubber, 15 parts of thermoplastic elastomer, 10 parts of talcum powder, 10 parts of carbon nanotubes, 5 parts Compatibilizer, 5 parts of light stabilizer, 3 parts of coupling agent, 2 parts of lubricant, 1.5 parts of antioxidant, 1.5 parts of dispersant.

[0040] The polypropylene is a copolymerized polypropylene with a melt flow rate of 200-1000 g / 10 min.

[0041] The grade of the thermoplastic elastomer is G155D.

[0042] The compatibilizer is a maleic anhydride grafted compatibilizer.

[0043] The light stabilizer is a combination of hindered amine light stabilizer and ultraviolet absorber UV-531.

[0044] The coupling agent is aminopropyltriethoxysilane.

[0045] The lubricant is oxidized paraffin.

[0046] The antioxidant is 2,6-tertiary butyl-4-methylphenol, bis(3,5-tertiary bu...

Embodiment 3

[0049] A low-temperature-resistant and impact-resistant automobile bumper material includes the following components in parts by mass: 45 parts of polypropylene, 20 parts of ethylene-propylene rubber, 10 parts of thermoplastic elastomer, 10 parts of talcum powder, 8 parts of carbon nanotubes, 4 parts Compatibilizer, 3 parts of light stabilizer, 2 parts of coupling agent, 1 part of lubricant, 1 part of antioxidant, 1.5 parts of dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com