Industrial greasy sludge and preparation method thereof

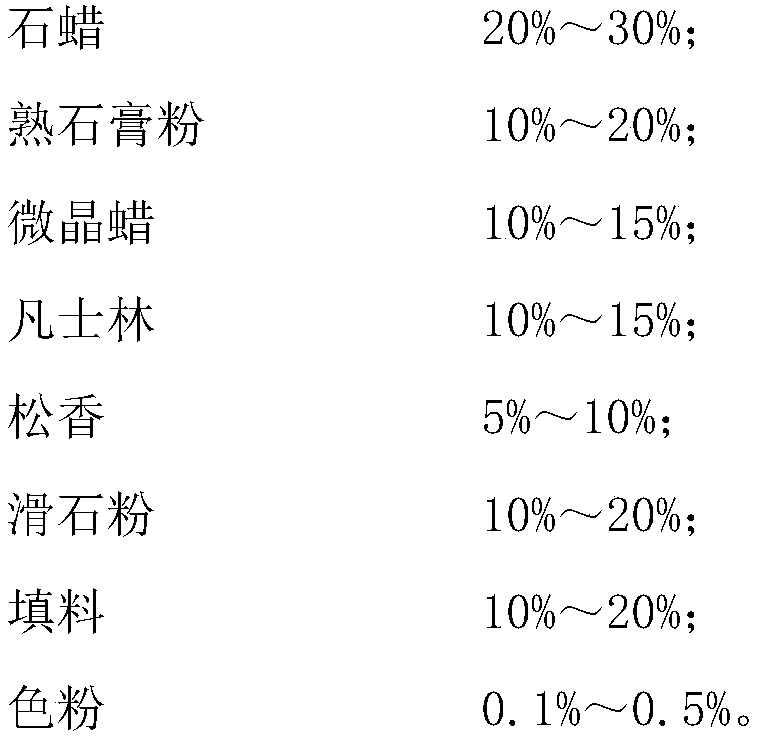

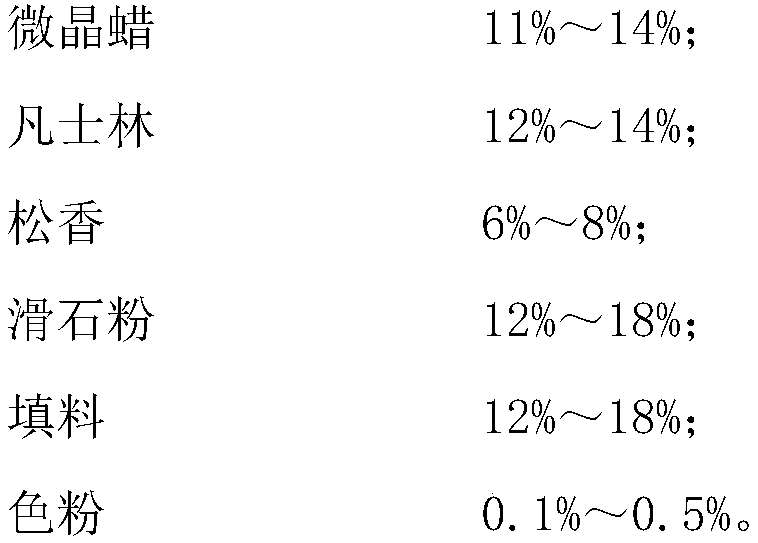

An industrial oil and sludge technology, applied in the field of sludge, can solve the problems of rough surface of sludge solid model, large scalability with temperature changes, complex production process, etc., and achieve the effect of no irritating smell, small shrinkage rate and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Weigh 25% of paraffin wax and 12% of microcrystalline wax according to the mass fraction, add them to the reaction kettle, heat to 150°C-200°C and keep it, so that the paraffin wax and microcrystalline wax are completely melted to obtain a spare wax liquid;

[0031] Step 2: Weigh 15% of calcined gypsum powder, 15% of talcum powder, and 13% of filler according to the mass fraction, and then add them to the spare wax liquid obtained in step 1 and stir. During the stirring process, the reaction kettle is heated, and the reaction kettle is heated in 30min~ Heat the internal temperature of the reactor to 500°C~600°C within 60 minutes, then keep stirring at this temperature for 2h~4h, then cool to 150°C~200°C while stirring, and cool to 150°C~600°C The time at 200°C is 40min~70min, and then continue to stir for 1h~4h until there is no fine group of powder, and the spare material is obtained;

[0032] Step 3: Weigh 13% of vaseline and 7% of rosin according to the mass ...

Embodiment 2

[0035] Step 1: Weigh 20% of paraffin wax and 15% of microcrystalline wax according to the mass fraction, add them to the reaction kettle, heat to 150°C-200°C and keep it, so that the paraffin wax and microcrystalline wax are completely melted to obtain a spare wax liquid;

[0036] Step 2: Weigh 15% of plaster powder, 15% of talcum powder, and 15% of filler according to the mass fraction, and then add them to the spare wax liquid obtained in step 1 and stir. During the stirring process, the reaction kettle is heated, and the reaction kettle is heated in 30min~ Heat the internal temperature of the reactor to 500°C~600°C within 60 minutes, then keep stirring at this temperature for 2h~4h, then cool to 150°C~200°C while stirring, and cool to 150°C~600°C The time at 200°C is 40min~70min, and then continue to stir for 1h~4h until there is no fine group of powder, and the spare material is obtained;

[0037] Step 3: Weigh 13% of vaseline and 7% of rosin according to the mass fraction...

Embodiment 3

[0040] Step 1: Weigh 30% of paraffin wax and 10% of microcrystalline wax according to the mass fraction, add them to the reaction kettle, heat to 150°C-200°C and keep it, so that the paraffin wax and microcrystalline wax are completely melted to obtain a spare wax liquid;

[0041] Step 2: Weigh 15% of plaster powder, 15% of talcum powder, and 15% of filler according to the mass fraction, and then add them to the spare wax liquid obtained in step 1 and stir. During the stirring process, the reaction kettle is heated, and the reaction kettle is heated in 30min~ Heat the internal temperature of the reactor to 500°C~600°C within 60 minutes, then keep stirring at this temperature for 2h~4h, then cool to 150°C~200°C while stirring, and cool to 150°C~600°C The time at 200°C is 40min~70min, and then continue to stir for 1h~4h until there is no fine group of powder, and the spare material is obtained;

[0042] Step 3: Weigh 10% of vaseline and 5% of rosin according to the mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com