A kind of method for preparing surface silver-plated composite material

A composite material, silver-plating technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of difficult to meet the high conductivity field, negative surface potential of aluminum powder, large specific surface area, etc. The effect of good plating effect, uniform and dense silver layer, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

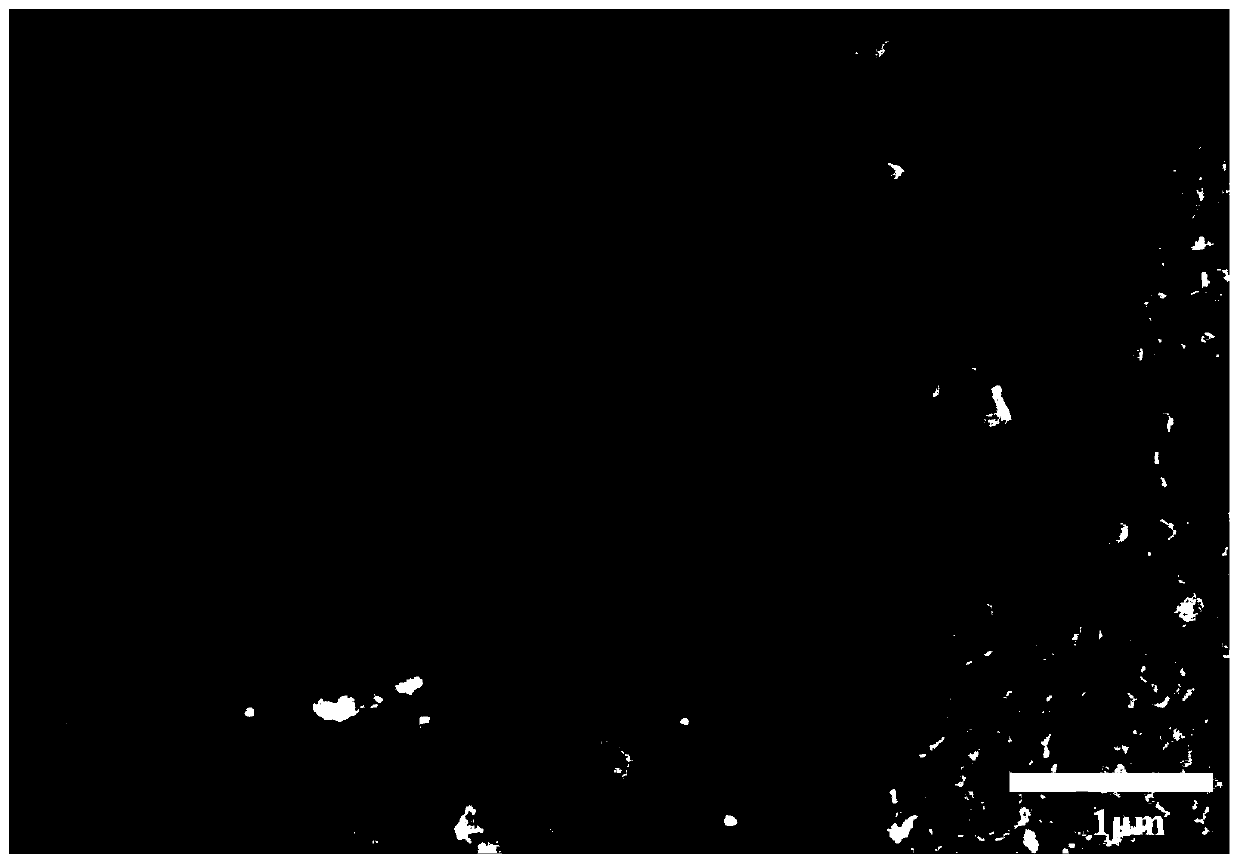

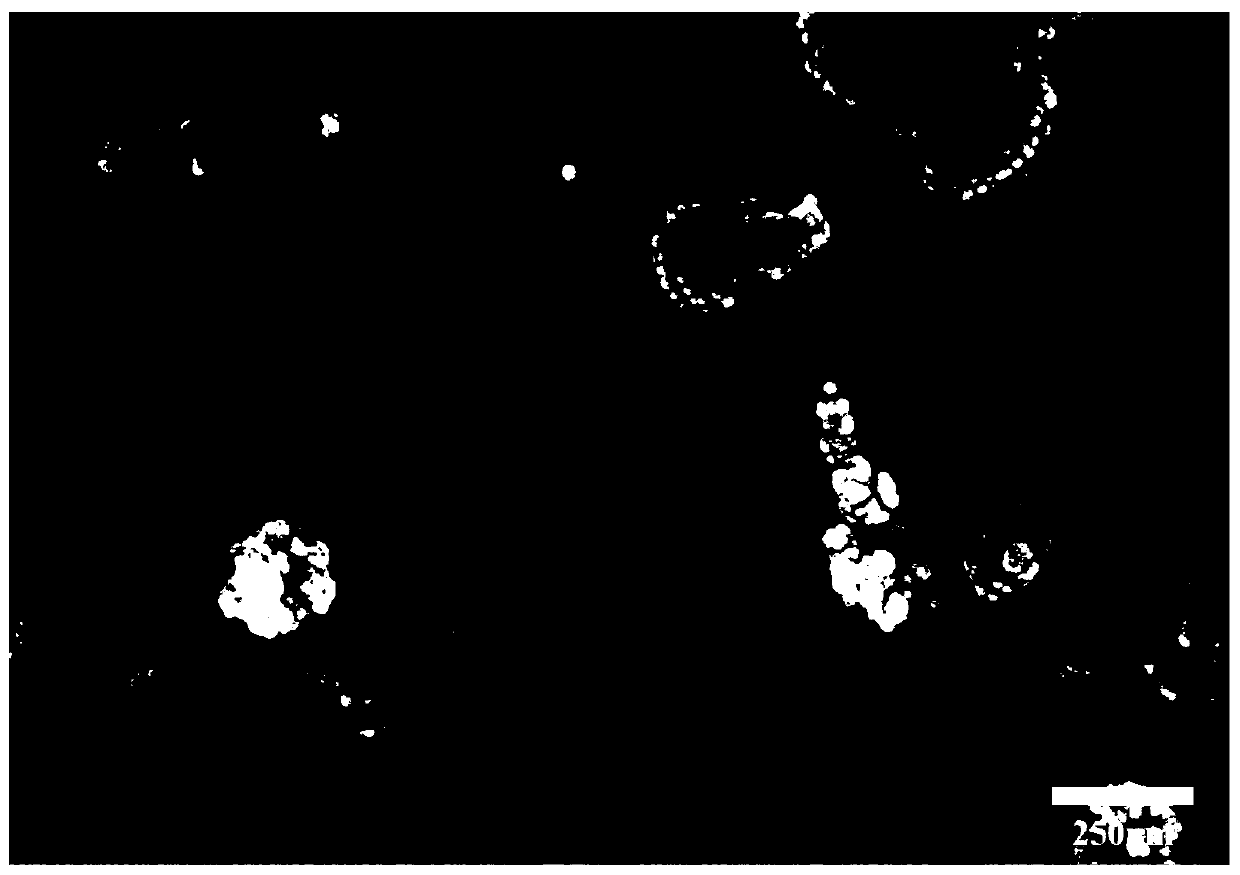

[0056] 1) After ultrasonically cleaning 4g of aluminum powder in ethanol solution, place it in a solution of 1.1g / L catechol and 1.0g / L diethylenetriamine, adjust the pH to 9 with Tris-HCl, and stir the reaction 4h, obtain the aluminum powder that surface is deposited with poly(catechol-polyamine);

[0057] 2) Add 4g of aluminum powder with poly(catechol-polyamine) deposited on the surface into 50ml of ethylene glycol solution in which 5mg of polyvinylpyrrolidone is dissolved, add 50ml of silver nitrate aqueous solution, the concentration is 12g / L, and then add 0.78 g n-octylamine, stirred and reacted for 60min, washed 3 times with ethanol to obtain aluminum powder with silver nanoparticles deposited on the surface;

[0058] 3) prepare 50ml concentration and be the silver nitrate solution of 10g / L, when titrating with ammoniacal liquor until precipitation just disappears, obtain silver plating solution;

[0059] 4) 4g of the aluminum powder that is deposited with silver nanop...

Embodiment 2

[0065] The process is the same as in Example 1, and the concentration of catechol and diethylenetriamine in step 1) is changed to 0.5, 1.5, 2, 2.5 g / L to obtain silver-coated aluminum powder.

[0066] After measurement, the electrical conductivity of the obtained silver-plated aluminum powder is 3333, 6667, 1.0×10 4 , 1.0×10 4 S / cm.

Embodiment 3

[0068] The process is the same as in Example 1, except that the diethylenetriamine in step 1) is changed to triethylenetetramine, tetraethylenepentamine, pentaethylenehexamine, hexaethyleneheptamine or polyethyleneimine to obtain silver-plated aluminum powder.

[0069] After measurement, the conductivity of the obtained silver-plated aluminum powder is 5000, 1.0×10 4 , 6667, 6667, 5000S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com