Novel hot-rolled air filtering aggregate and manufacturing method thereof

A technology of air filtration and production method, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of short service life of filter materials, large filtration pressure difference, cumbersome process, etc., to increase the contact surface area, maintain low pressure difference, and good The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A new type of hot-rolled air filter bone material, calculated by mass percentage, is made by mixing the following raw material components: 15D polyester staple fiber 80%; 7D modified polyester staple fiber 20%; 15D polyester staple fiber has a service temperature of 120- 150°, 7D modified polyester staple fiber has a sheath-core structure, the sheath layer and the core layer each account for 50%; the use temperature of the sheath layer is 110-140°, and the use temperature of the core layer is 120-150°.

[0027] The fiber length of 15D polyester staple fiber includes 32mm, 48mm, 51mm, 64mm and 76mm; the fiber length of 7D modified polyester staple fiber includes 32mm, 48mm, 51mm, 64mm and 76mm.

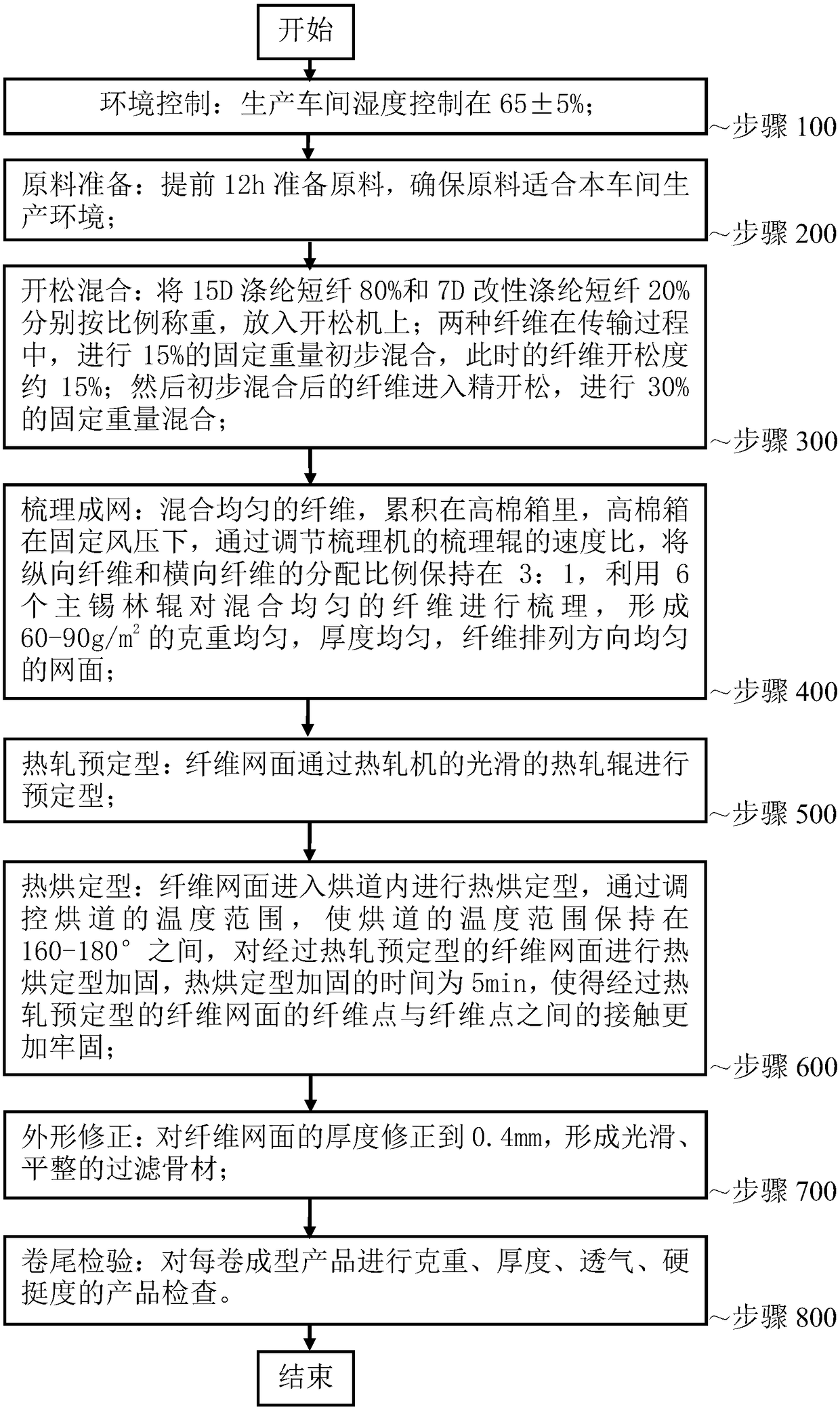

[0028] A new type of hot-rolled air filter aggregate manufacturing method, such as figure 1 As shown, including the following steps:

[0029] Step 100, environmental control: the humidity of the production workshop is controlled at 65±5%;

[0030] Step 200, raw material preparation: pr...

Embodiment 2

[0040] A new type of hot-rolled air filter aggregate, calculated by mass percentage, is made by mixing the following raw material components: 15D polyester staple fiber 60%; 7D modified polyester staple fiber 40%; 15D polyester staple fiber has a service temperature of 120- 150°, 7D modified polyester staple fiber has a sheath-core structure, the sheath layer and the core layer each account for 50%; the use temperature of the sheath layer is 110-140°, and the use temperature of the core layer is 120-150°.

[0041] The fiber length of 15D polyester staple fiber includes 32mm, 48mm, 51mm, 64mm and 76mm; the fiber length of 7D modified polyester staple fiber includes 32mm, 48mm, 51mm, 64mm and 76mm.

[0042] A manufacturing method of a new type of hot-rolled air filter aggregate includes the following steps:

[0043] (1) Environmental control: the humidity of the production workshop is controlled at 45±5%;

[0044] (2) Raw material preparation: Prepare raw materials 12 hours in advance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Dimension length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com