Steam-curing constant-temperature thermal insulation system for large-area inclined concrete pavement

A technology for concrete pavement and thermal insulation system, which is applied in the directions of roads, roads, and road repairs, can solve the problems of uneven and continuous compaction of pavement concrete surfaces, differences in concrete steam curing conditions, increased fuel power consumption, etc., and achieves good steam distribution. Uniformity, good compactness, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

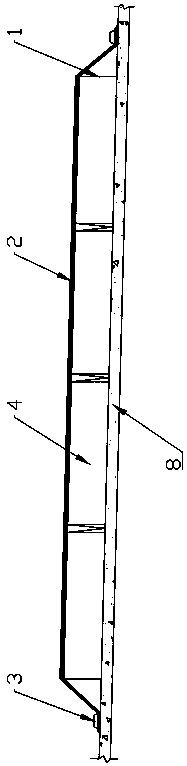

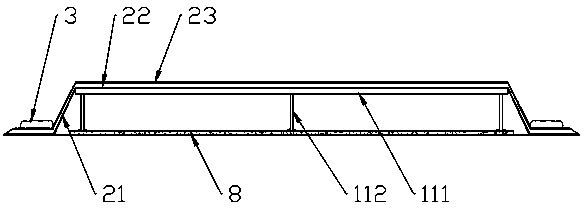

[0020] Such as figure 1 — Figure 5 As shown, a steam-cured constant-temperature heat preservation system for a large-area inclined concrete pavement in this embodiment includes a steam-cured frame 1, an insulation layer 2, and a windproof net 7.

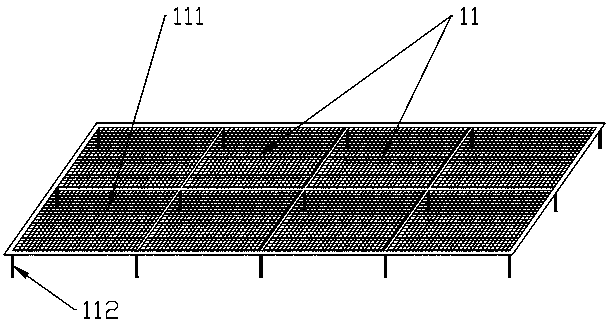

[0021] The steam curing frame 1 is installed on the cast-in-place concrete, and it is assembled by a plurality of standard block grids 11, and the standard block grid 11 includes a metal mesh sheet 111 and a grid screw 112, and the metal mesh The sheet 111 is composed of a metal mesh and a frame around the metal mesh, and the mesh frame screw 112 is fixedly connected to the frame screw ports on the four sides of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com