Coal bed gas extraction hole drilling viscose liquid dynamic recyclable hole sealing device and coal bed gas extraction hole drilling viscose liquid dynamic recyclable hole sealing method

A technology for drilling and coal seam gas drainage, applied in gas discharge, safety devices, mining equipment, etc., can solve the problems of long sealing time, difficult infiltration, poor permeability, etc., achieve simple design, improve gas drainage efficiency, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

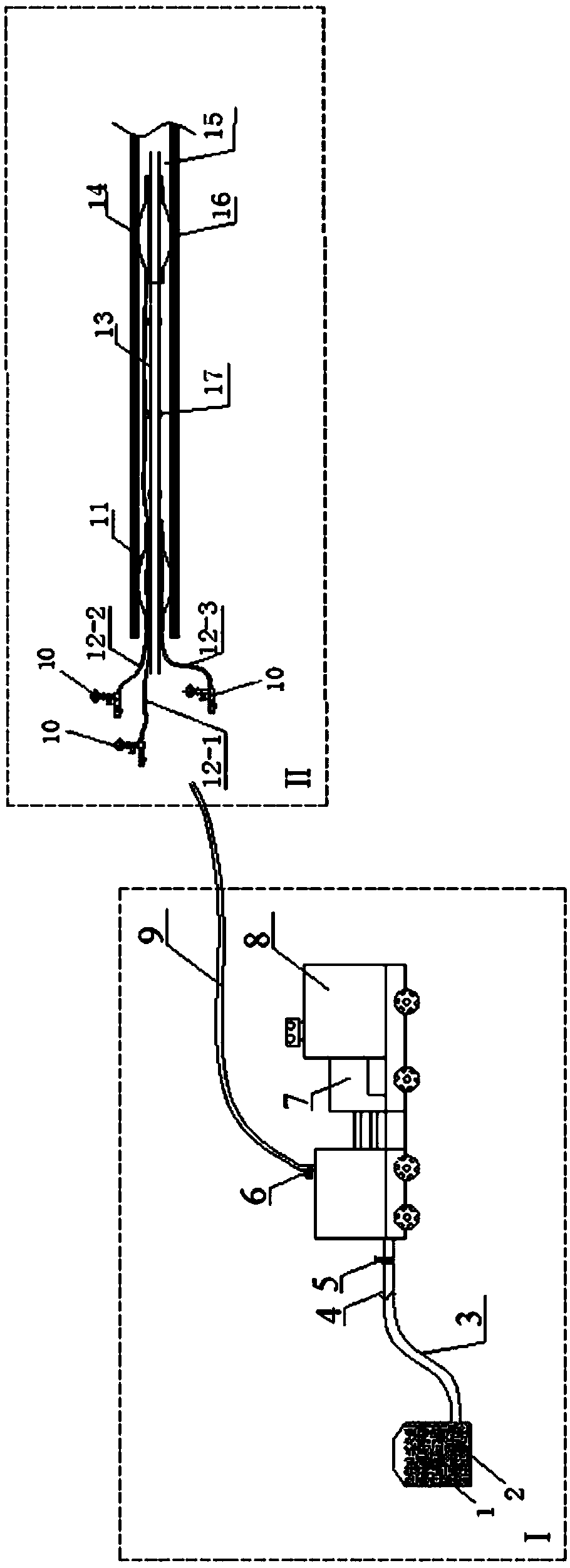

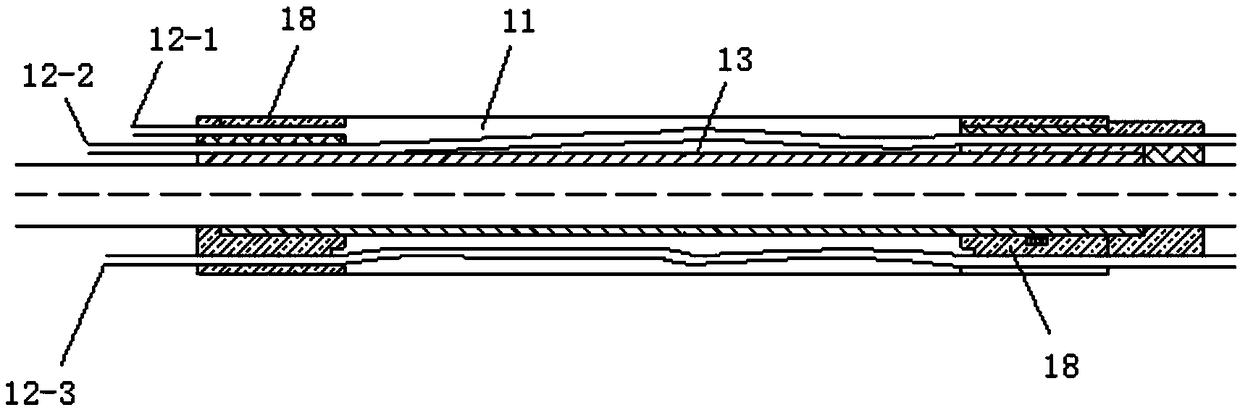

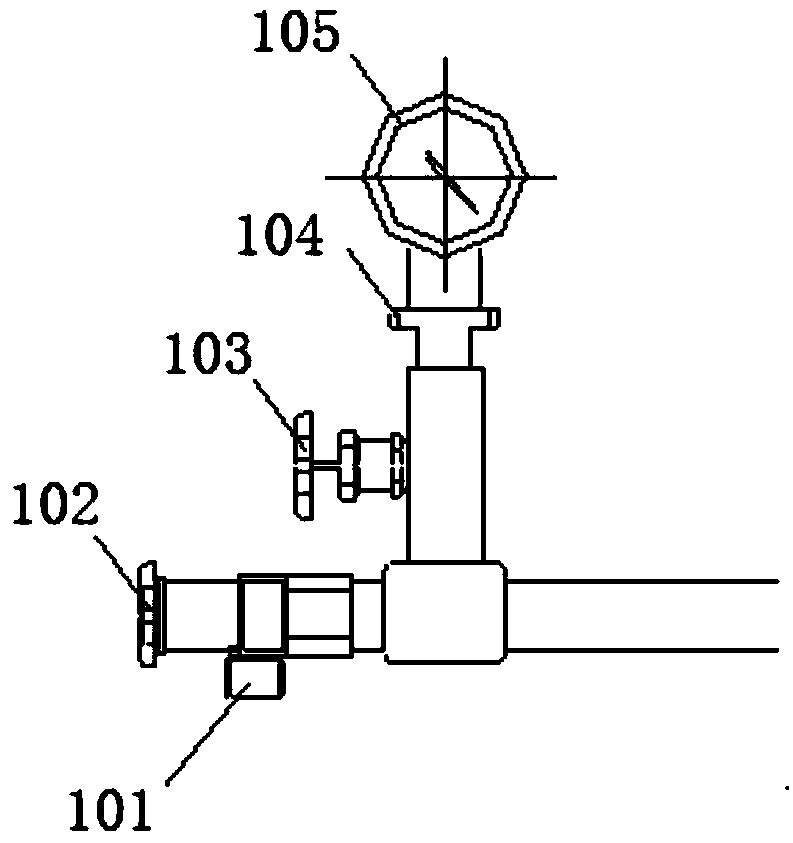

[0029] Such as Figure 1-Figure 3 As shown, this embodiment provides a dynamic recyclable hole sealing device for drilling mucus in coal seam 16 gas drainage, which is used to seal the borehole section in coal seam 16, including dynamic grouting system I and static sealing system II, The static sealing system II includes three second high-pressure hoses, orifice expansion capsule 11, hole end expansion capsule 14 and sealing tube 13, wherein the sealing tube 13 is placed in the borehole, orifice expansion capsule 11 and hole end The expansion capsules 14 are set at intervals and set outside the sealing tube 13, the side of the expansion capsule 14 at the end of the hole close to the hole is the plugging section, the first ends of the three second high-pressure hoses are all free ends, and the three second high-pressure flexible hoses are free ends. The second end of the tube is respectively connected to the expansion capsule 11 at the orifice, the expansion capsule 14 at the e...

Embodiment 2

[0037] This embodiment provides a method for dynamically recyclable hole sealing of coal seam 16 gas drainage drilling mucus, using the coal seam 16 gas drainage drilling mucus dynamic recyclable sealing device as in Example 1, including the following steps,

[0038] Step 1. Connect the two middle hoses 12 with the orifice expansion capsule 11 and the hole end expansion capsule 14 respectively before sealing the hole, and set the orifice expansion capsule 11 and the hole end expansion capsule 14 on the sealing tube 13;

[0039] Step 2, send the connected orifice expansion capsule 11, the hole end expansion capsule 14 and the hole sealing tube 13 into the drilling hole sealing section 15;

[0040] Step 3, place the glue feeding hose 3 at the bottom of the liquid storage container 2, the liquid storage container 2 is filled with viscous colloid, and connect the glue feeding hose 3 and the pressurized glue injection pump 7;

[0041] Step 4, connect the pressurized glue injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com