Oil production device and method for controlling pressure of oil layer through double-layer oil pipe

It is a technology for oil layer pressure and oil production equipment, which is applied in the direction of drilling pipe, casing, and production fluid, etc. It can solve the problems of affecting liquid production, degassing of crude oil in the upper oil layer, and large pressure difference in the upper oil layer, so as to improve operation reliability, Improve the stress condition and reduce the effect of pressure interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

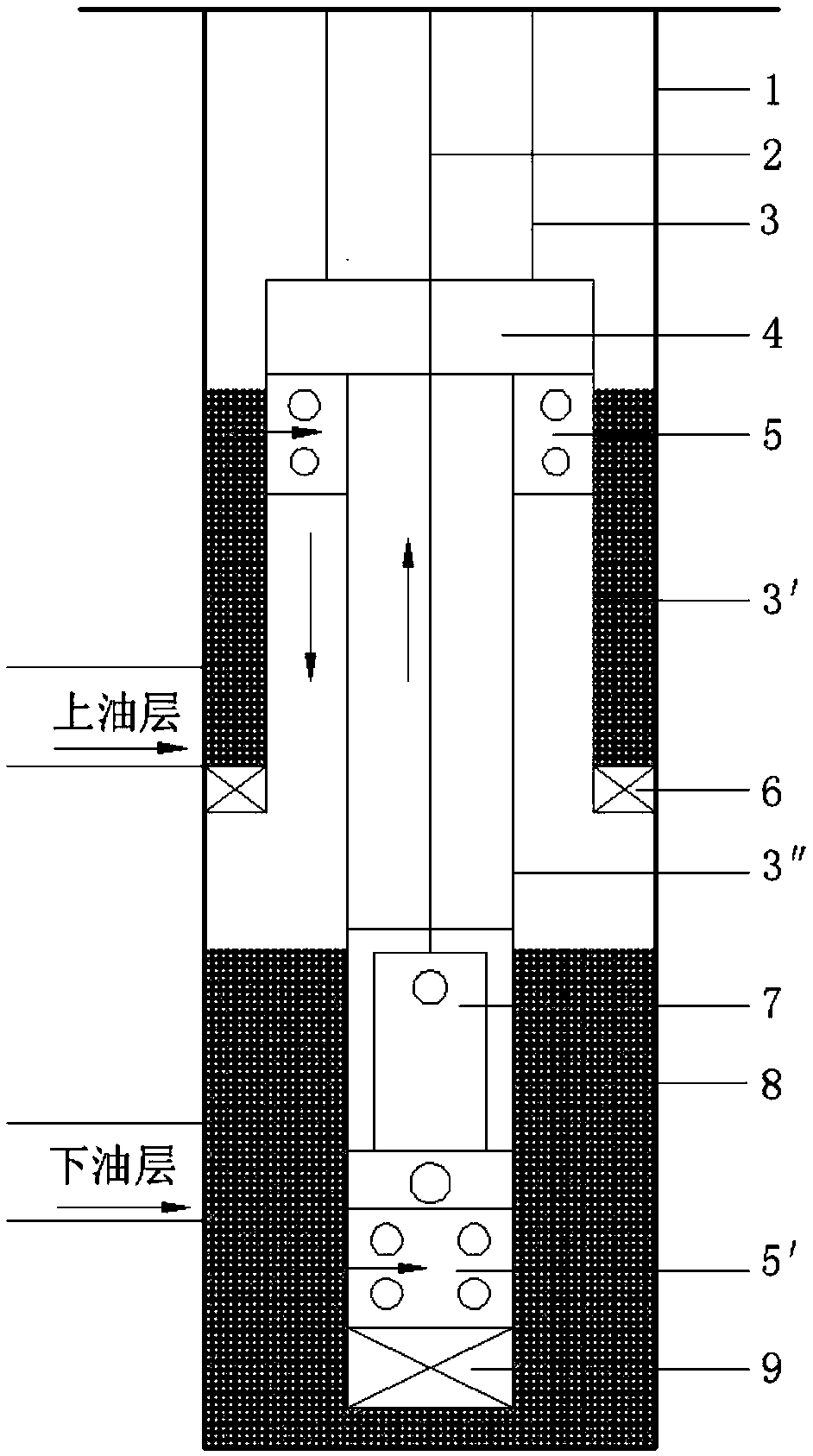

[0017] Specific embodiments: The present invention will be further described below in conjunction with the accompanying drawings: a kind of oil production device for controlling the oil layer pressure with double-layer oil pipes consists of casing 1, sucker rod 2, oil pipe one 3, oil pipe buckle 4, screen pipe one 5, oil pipe Two 3', slip packer 6, tubing three 3", plunger 7, pump barrel 8, screen tube two 5', and plug 9; the upper end of tubing buckle 4 in casing 1 is connected with tubing one 3 screw connections, the lower end of tubing change button 4 is connected with screen tube 1 5 with screws, screen tube 1 5 is connected with tubing 2 3′, and slip packer 6 in sequence, and tubing 3 3″ is connected with pump barrel 8, The screen tube 2 5' and the plug 9 are connected with screws in turn, and the plunger 7 is connected with the sucker rod 2 with screws.

[0018] The oil production method of an oil production device using a double-layer oil pipe to control the pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com