Air flotation main shaft bearing compensation device and method

An air-floating spindle and compensation device technology, which is applied to bearings, hydrostatic bearings, shafts and bearings, etc., can solve the problems of difficult to guarantee machining accuracy, increased spindle rotation error, and wear and tear of the air-floated spindle, and achieve real-time compensation. , High loading accuracy, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

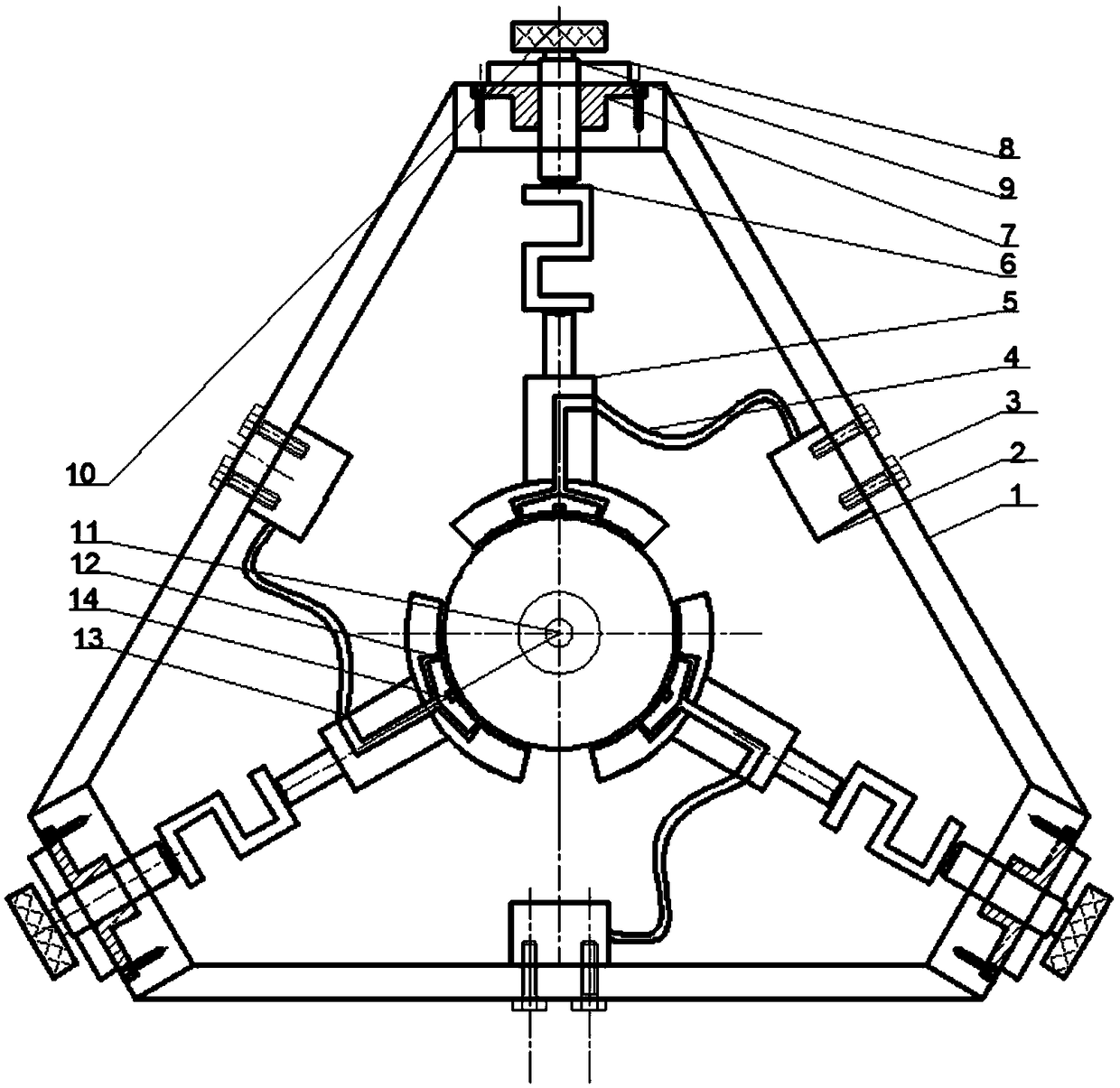

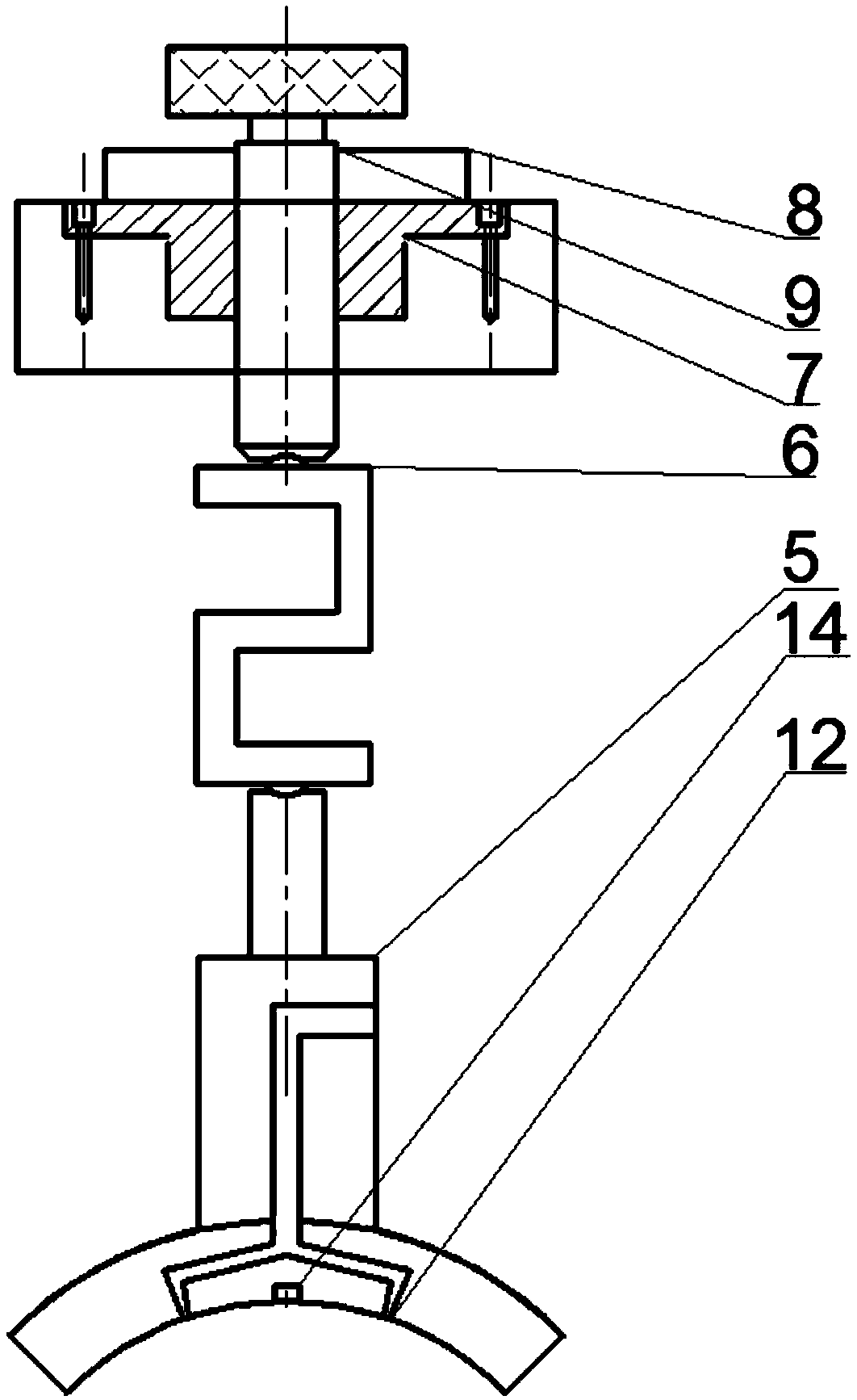

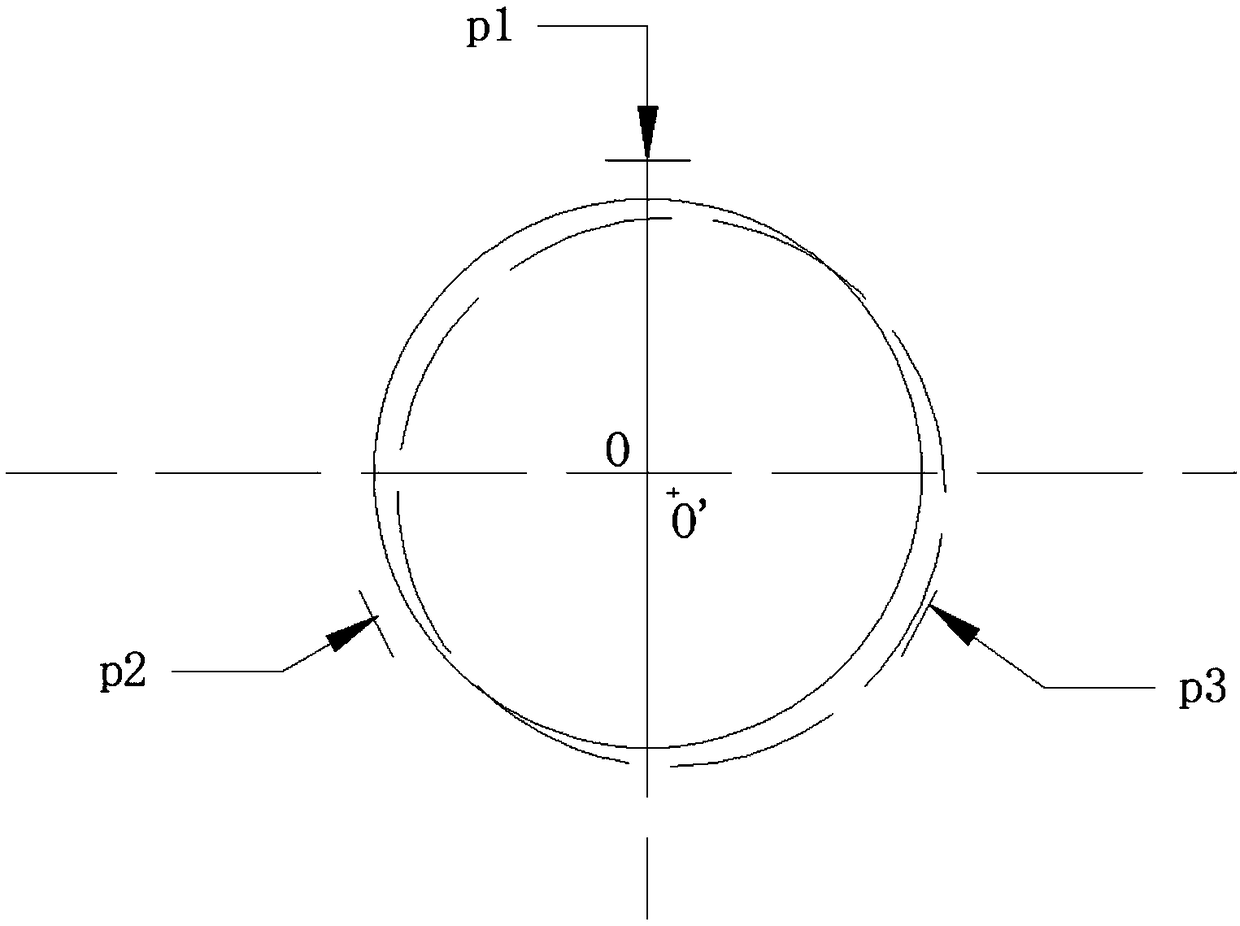

[0027] Such as figure 1 , 2 As shown in and 5, the air bearing main shaft carries the compensation device, including the fixed bracket 1, the control valve 2, the air pipe 4 and the air bearing assembly; the fixed bracket 1 is used for the support of the control valve 2 and the air bearing assembly; the fixed bracket is hollow inside Triangular, the triangle is more stable; the fixed bracket is provided with three stepped holes uniformly distributed along the circumferential direction, and the hole section with a larger diameter of the stepped holes is set outward; three air bearing components are evenly distributed along the circumferential direction. The position of the assembly corresponds to the position of the stepped hole; the air bearing assembly includes the air bearing 5, the centering adjustment rod 9, the centering adjustment rod sleeve 7, the pressure sensor 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com