Container welding device and welding system containing same

A welding device and welding position technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of poor weld quality, inability to prevent excessive temperature rise in the weld area, inconvenience, etc., and achieve simplified loading of flux, Simple structure, effect of preventing radiation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

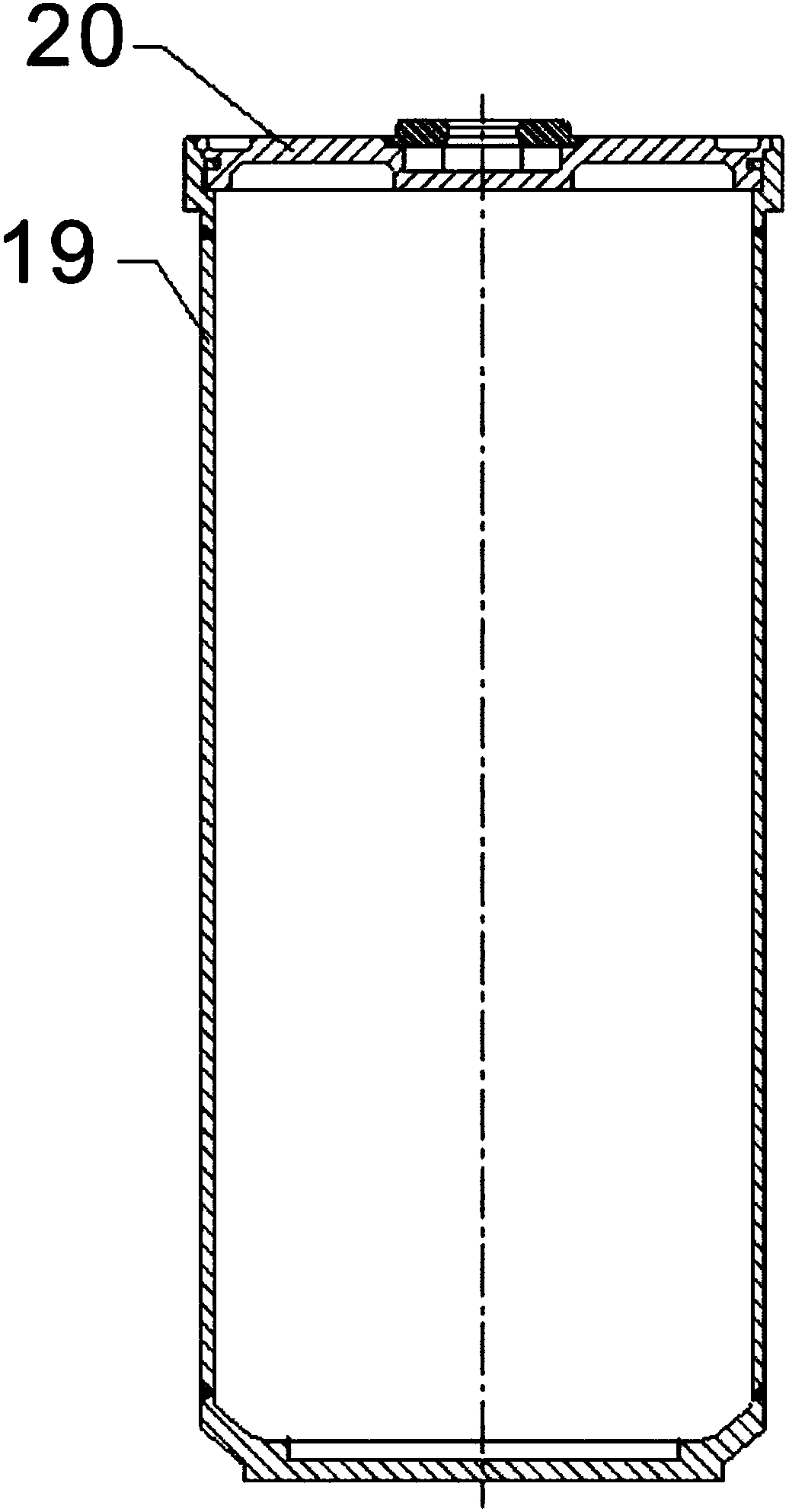

[0040] The present invention provides a container welding device for welding a container 13. The structure of the container 13 is as follows figure 1 As shown, a container body 19 and a container cover 20 are included.

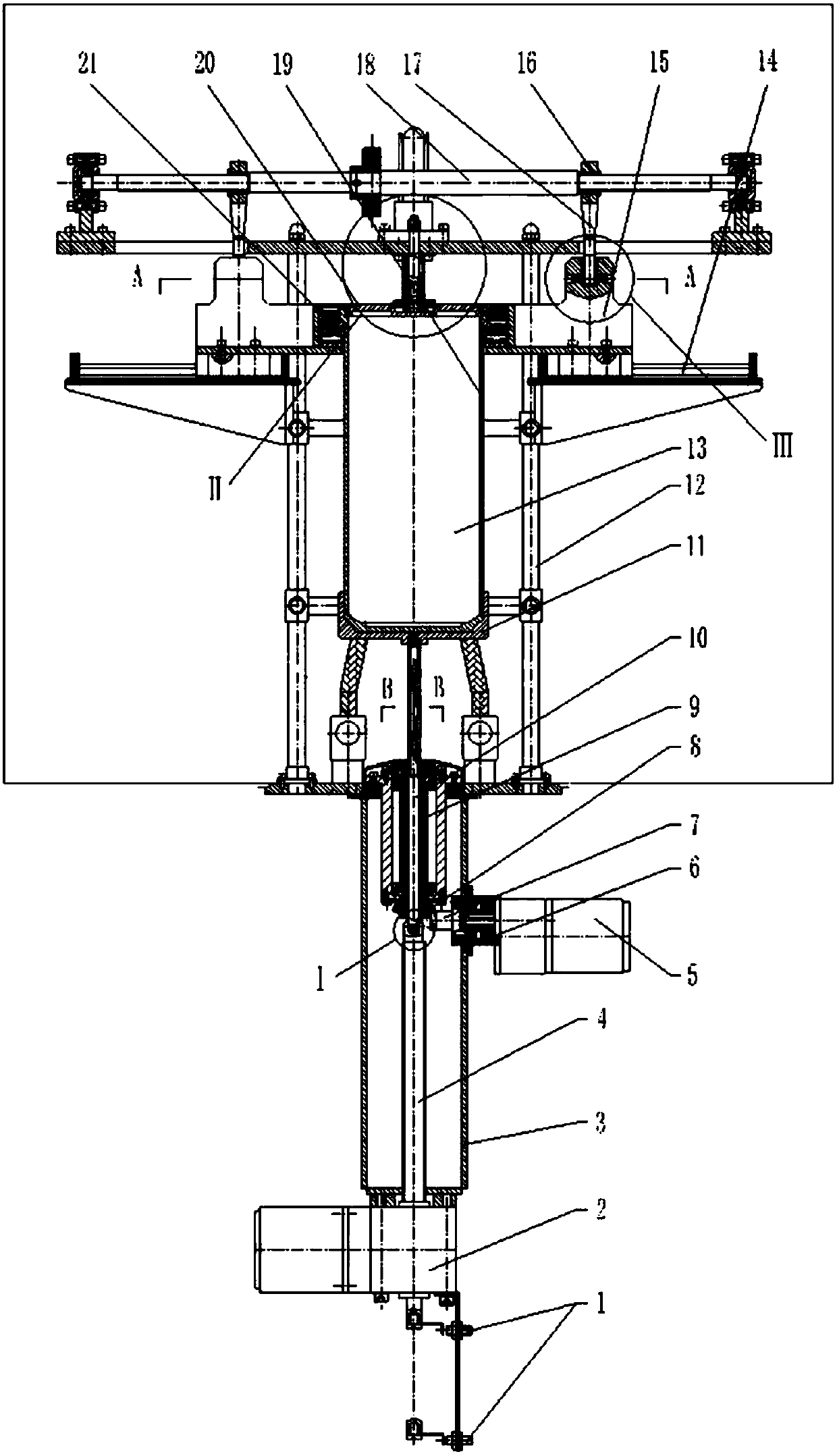

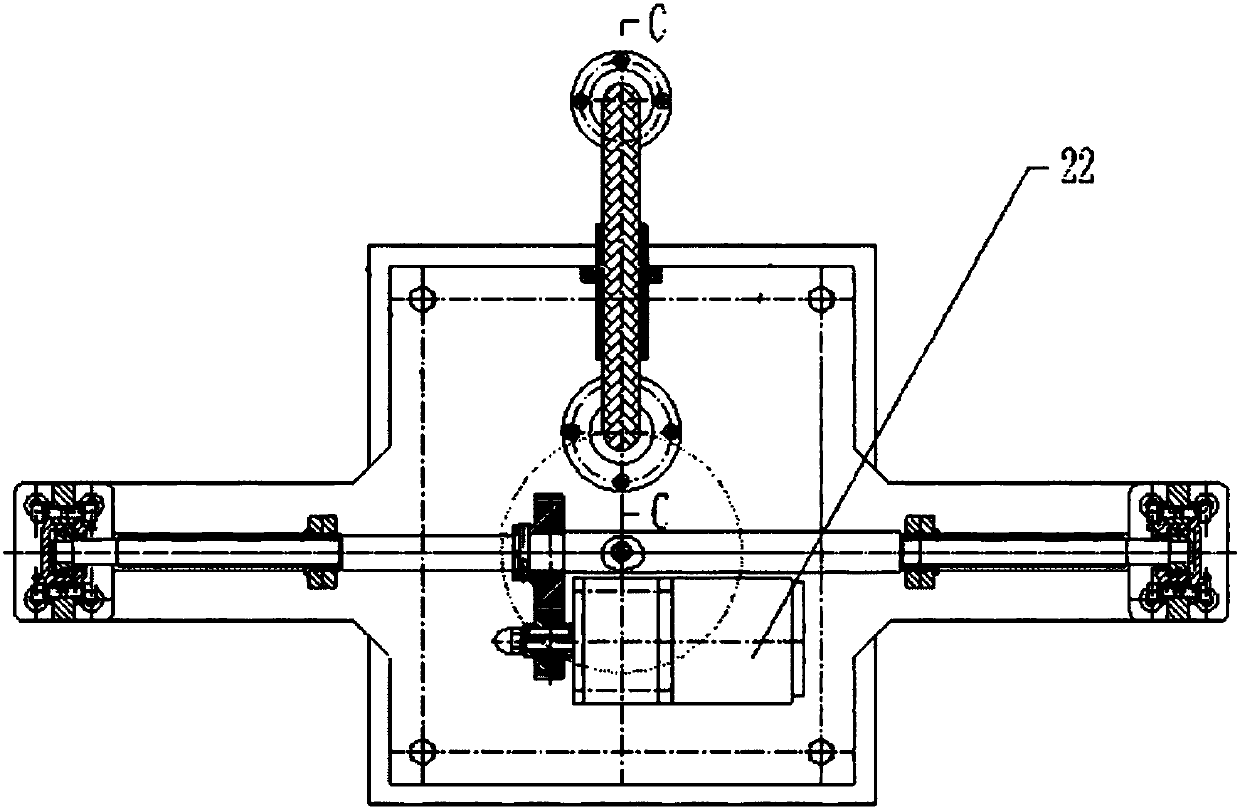

[0041] The container welding device provided by the invention is as figure 2 As shown, it comprises a container tank 11, a lifting device, a rotating device and a welding device; the container tank 11, a lifting device, a rotating device and a welding device are all arranged in a heat chamber and are relatively fixed with the heat chamber; The container tank 11 is connected to control the lifting movement of the container tank 11; the rotating device is connected to the container tank 11 to control the rotational movement of the container tank 11; the welding torch 24 of the welding device is welding the container 13 to be welded. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com