Reversing valve and rotating valve core thereof

A technology of rotating spool and reversing valve, applied in valve details, multi-way valves, valve devices, etc., can solve the problem of many components, achieve low production cost, ensure fit, and increase sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

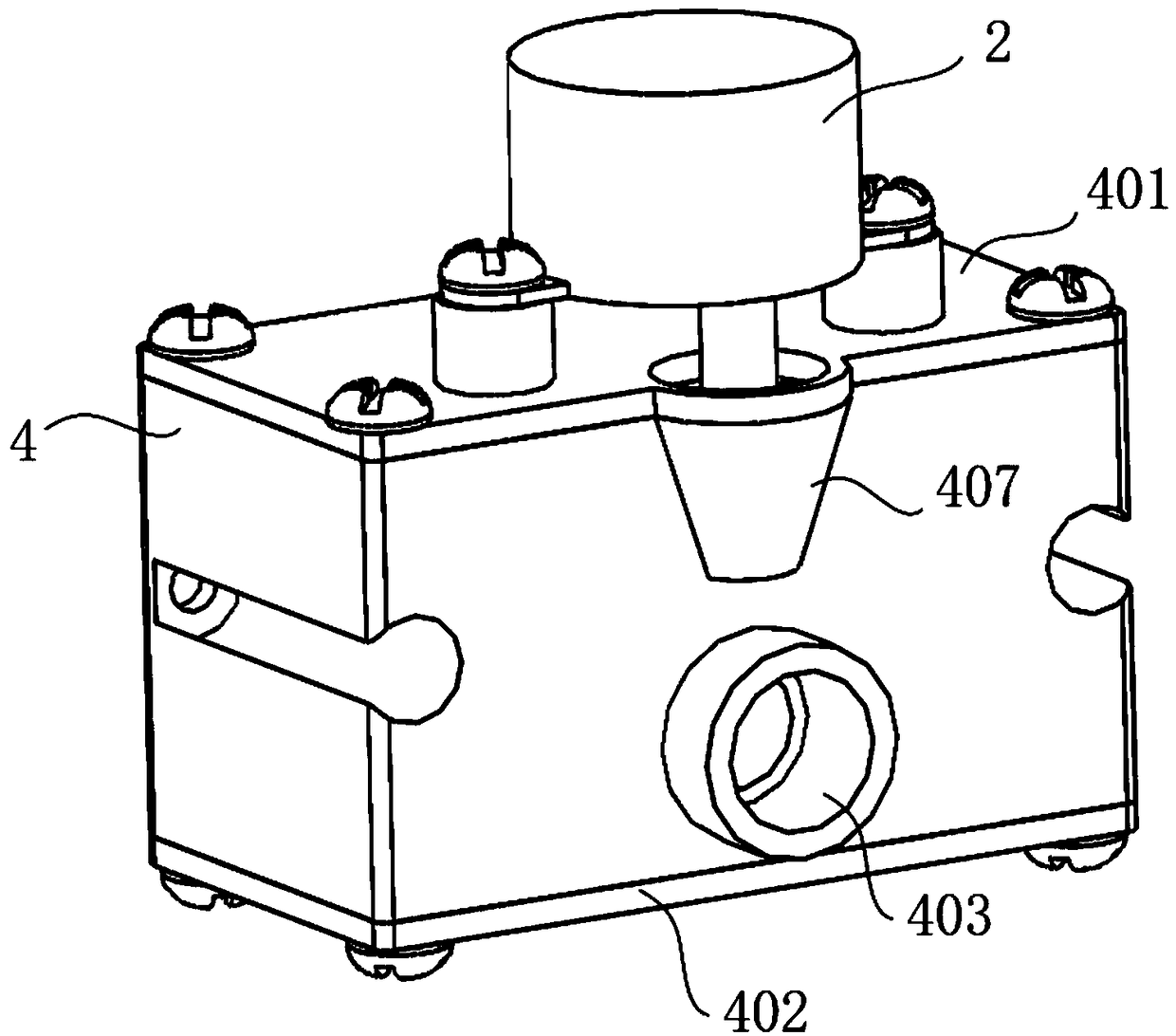

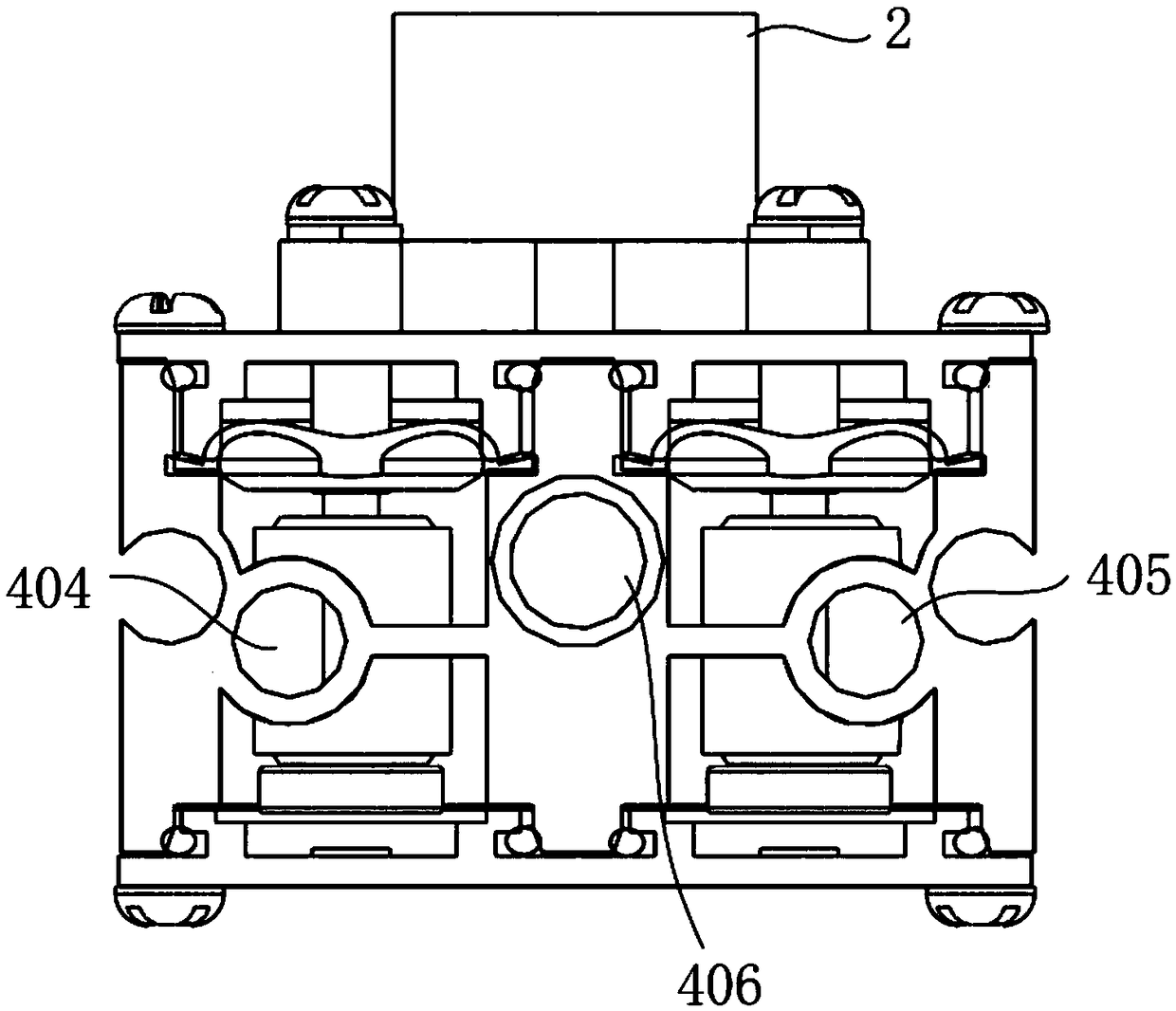

[0055] see figure 1 , Figure 5 , is a structural schematic diagram of a reversing valve, which is mainly used for valve bodies that require two or more pilot chambers to be controlled, especially in oxygen generators. The reversing valve in this embodiment includes a rotary valve core 1, a valve body 4 and a driving device 2, wherein the rotary valve core 1 includes an air inlet 105, a pressure relief port 104 and an air induction port, please refer to Figure 10 to Figure 15 , the outer contour of the rotary spool 1 is a cone shape, of course, the rotary spool 1 is not limited to the cone shape, it can also be a cylindrical shape, or other shapes, and the top of the rotary spool 1 is provided with a mounting hole 101, the installation The hole 101 extends downward from the upper surface 108 of the rotary spool and along the central axis of the rotary spool, and is a blind hole for connecting the output shaft of the drive device 2. The drive device 2 of this embodiment selec...

Embodiment 2

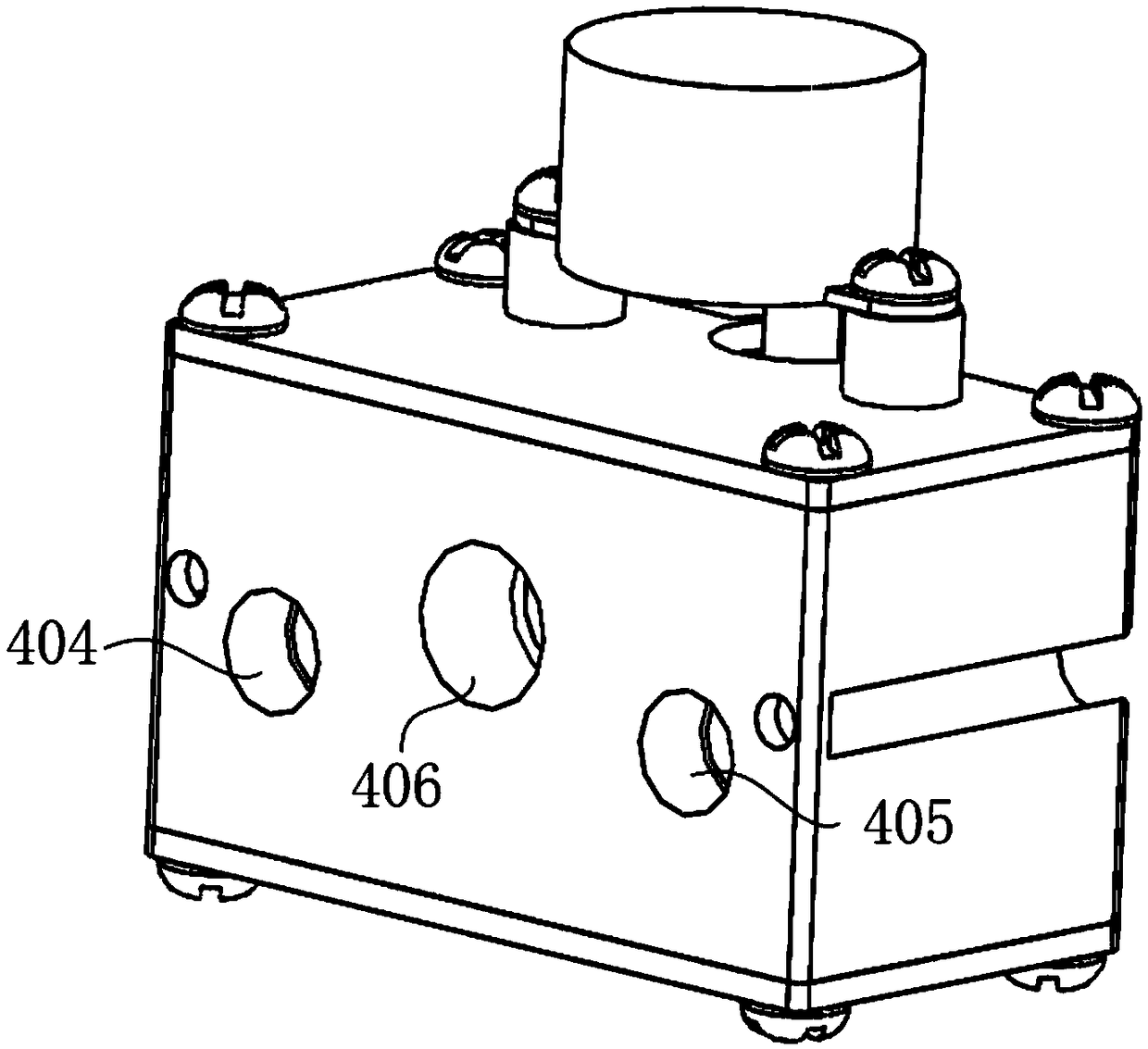

[0084] On the basis of Example 1, please refer to Figure 9 and Figure 18 , the valve body of the reversing valve in this embodiment includes an upper cover plate 401 and a lower cover plate 402, wherein the upper cover plate 401 has a circular protrusion extending downward above the corresponding pilot cavity, and the circular protrusion on the circular ring A side wall air-introduction channel 419 is provided on the protrusion. It is also necessary to pay special attention to that the side wall air-induction channel 419 on the annular protrusion and the aforementioned air introduction port and pressure relief port 104 are relative to the rotary valve core 1. The heights of the bottoms are equal to ensure that during the rotation of the rotary valve core 1 in the inner cavity 407, the air-introduction port and the pressure relief port-104 can be periodically connected with the inlet of the side wall air-introduction channel 419 for pressurization, or pressure relief. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com