Drying equipment with adjusting function and special for textile fabrics

A technology for textile fabrics and drying equipment, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of inconvenient adjustment of wind deflectors and lack of angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

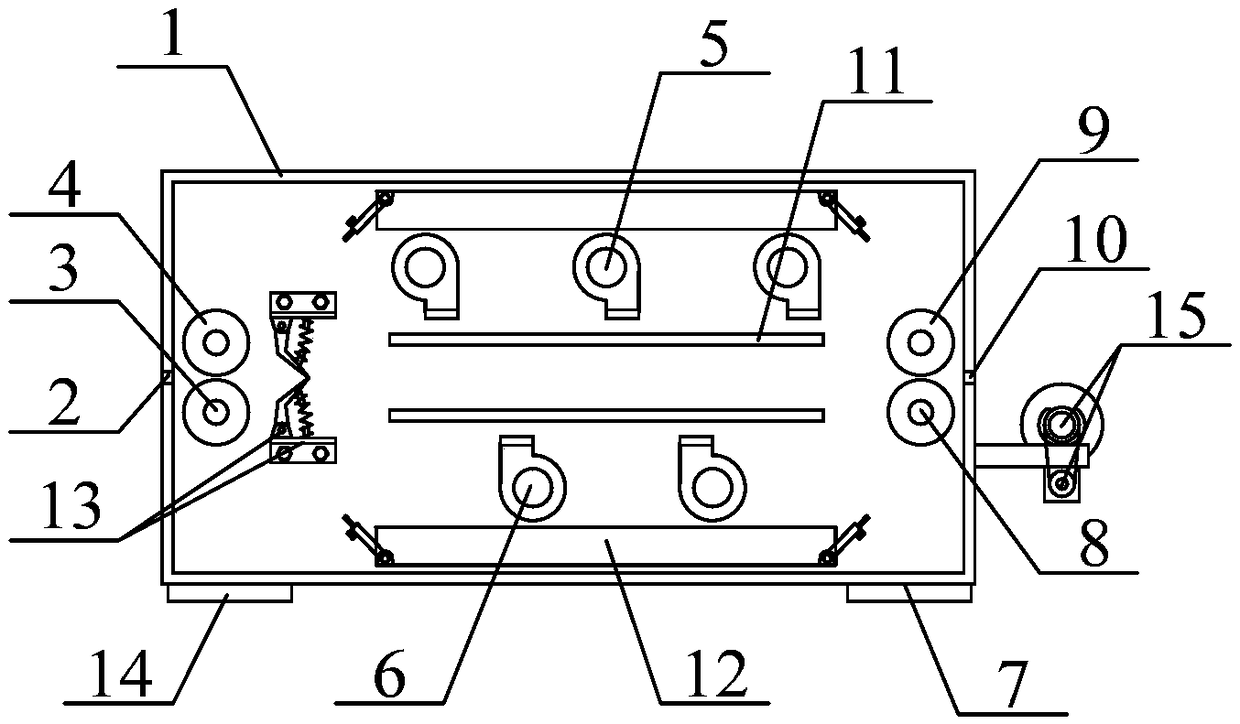

[0032] The present invention will be further described below in conjunction with accompanying drawing:

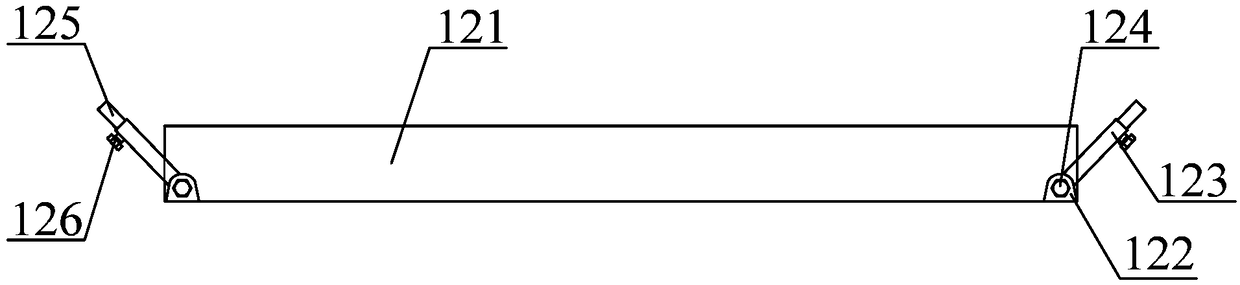

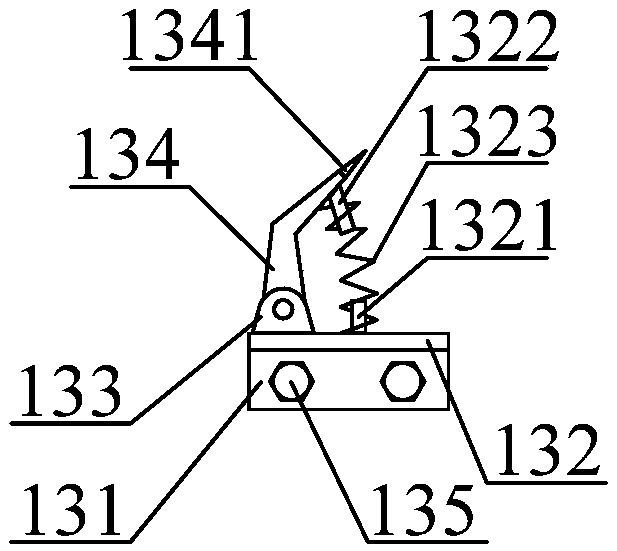

[0033] as attached figure 1 And attached image 3As shown in the present invention, a special drying equipment for textile fabrics with adjustment function, including a rectangular storage frame 1, a left feeding frame 2, a left fixing rod 3, a left auxiliary wheel 4, an upper fan 5, The lower fan 6, the right foot 7, the right fixed rod 8, the right auxiliary wheel 9, the right discharge frame 10, the horizontal electric heating wire mesh 11, the adjustable wind guide frame structure 12, the auxiliary scraper frame structure 13, The left side leg 14 and the textile fabric collecting rack structure 15, the left side feeding frame 2 is embedded in the left side of the middle part of the rectangular storage frame 1; the left side fixing rod 3 is pivotally connected to the left side of the inner wall of the rectangular storage frame 1 the middle position; the left auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com