Testing system for instrument for simulating startup visual durability of real car key

A test system and durability technology, applied in vehicle testing, closed-circuit television system, machine/structural component testing, etc., can solve problems such as undetectable, black screen discovery, process data loss, etc., to achieve a convenient test environment and release Human resources, the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

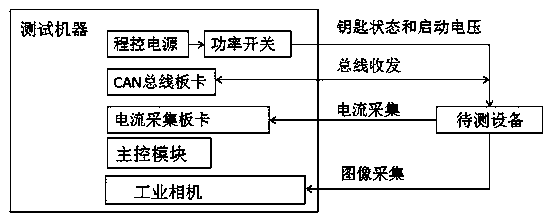

[0026] Such as figure 1 As shown, the present invention provides a visual durability instrument test system for simulating real car keys, which is characterized in that it includes a main control module: used to control the work of other modules and compare and analyze the data transmitted from other modules, and output the test Report; data transmission module: including the CAN bus board for transmitting bus data to the test equipment and the current acquisition board for transmitting current signals to the test equipment, the CAN bus board and the current acquisition board are all Connected with the device under test for transmitting detection data to the device under test; visual detection module: including an industrial camera, the camera of the industrial camera is set relative to the display module of the device under test for real-time shooting of the operation of the device under test; Power module: It is used to supply power to the entire test system and the equipmen...

Embodiment 2

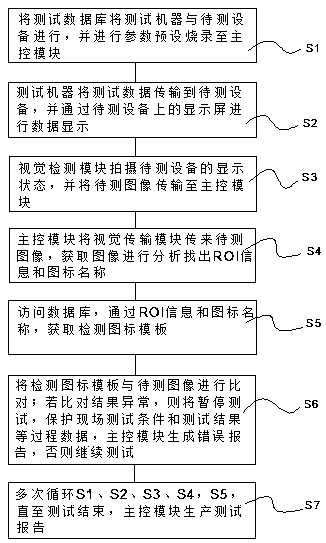

[0029] Based on Embodiment 1, the present invention also provides a method for testing a visual durability meter that simulates a real car key starting, including the following steps: S1: perform a test on the test machine and the device to be tested, and perform parameter presets; S2: the test machine will test The data is transmitted to the device under test, and the data is displayed on the display screen of the device under test; S3: the visual detection module captures the display status of the device under test, and transmits the image to be tested to the main control module; S4: the main control module will The image to be tested is transmitted from the visual transmission module, and the image is obtained for analysis to find out the ROI information and icon name; S5: Access the database, and obtain the detection icon template through the ROI information and icon name; S6: Compare the detection icon template with the image to be tested Yes; if the comparison result is a...

Embodiment 3

[0033] Based on Embodiment 2, further, in the step S11, the database generation includes the following steps: S111: Initialize the visual system variables; S112: Drive the camera to capture the working image of the device under test, and obtain the ROI position information of the image; S113: Determine whether It is necessary to save the icon template and ROI coordinate data in the ROI. If it needs to be saved, it will be stored in the specified data calibration storage path according to the name specified by the user; S114: Determine whether the icon and ROI coordinate data in the currently selected ROI need to be deleted. If it needs to be saved , delete the data from the specified data standard storage path. S115: Write test execution instruction data and result inspection data corresponding to the icon information, and generate a test script. S115: Summarize all icon information and test scripts, and generate a database.

[0034] Further, the test data includes at least on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com