Indoor forklift positioning method and system

A positioning system and forklift technology, applied in the field of indoor positioning systems in industrial environments, can solve the problems that positioning equipment cannot meet high-precision positioning requirements, sound wave transmission conditions are limited, and positioning accuracy does not have obvious advantages, and achieve high positioning accuracy. The effect of reducing error rate and improving management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

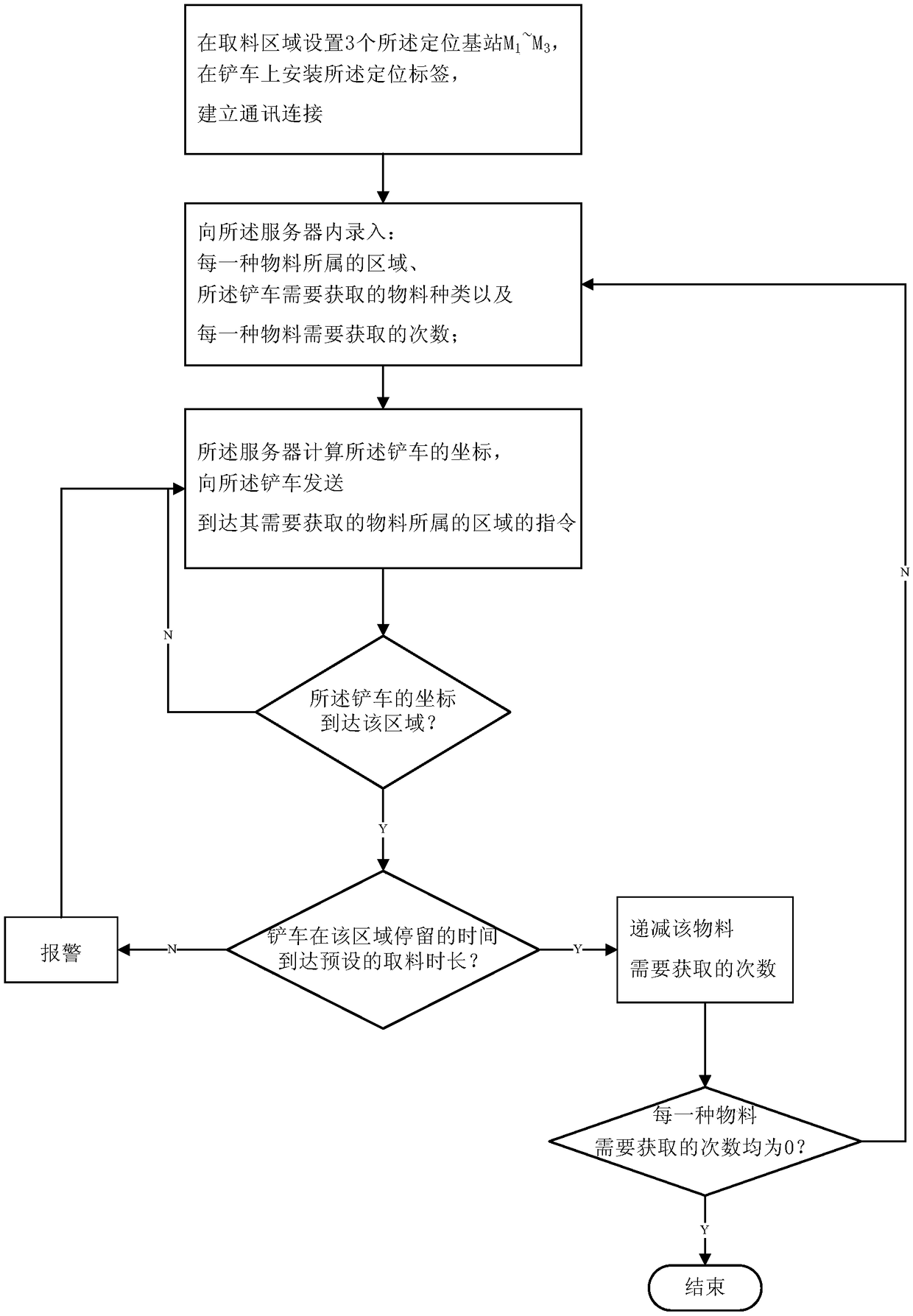

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

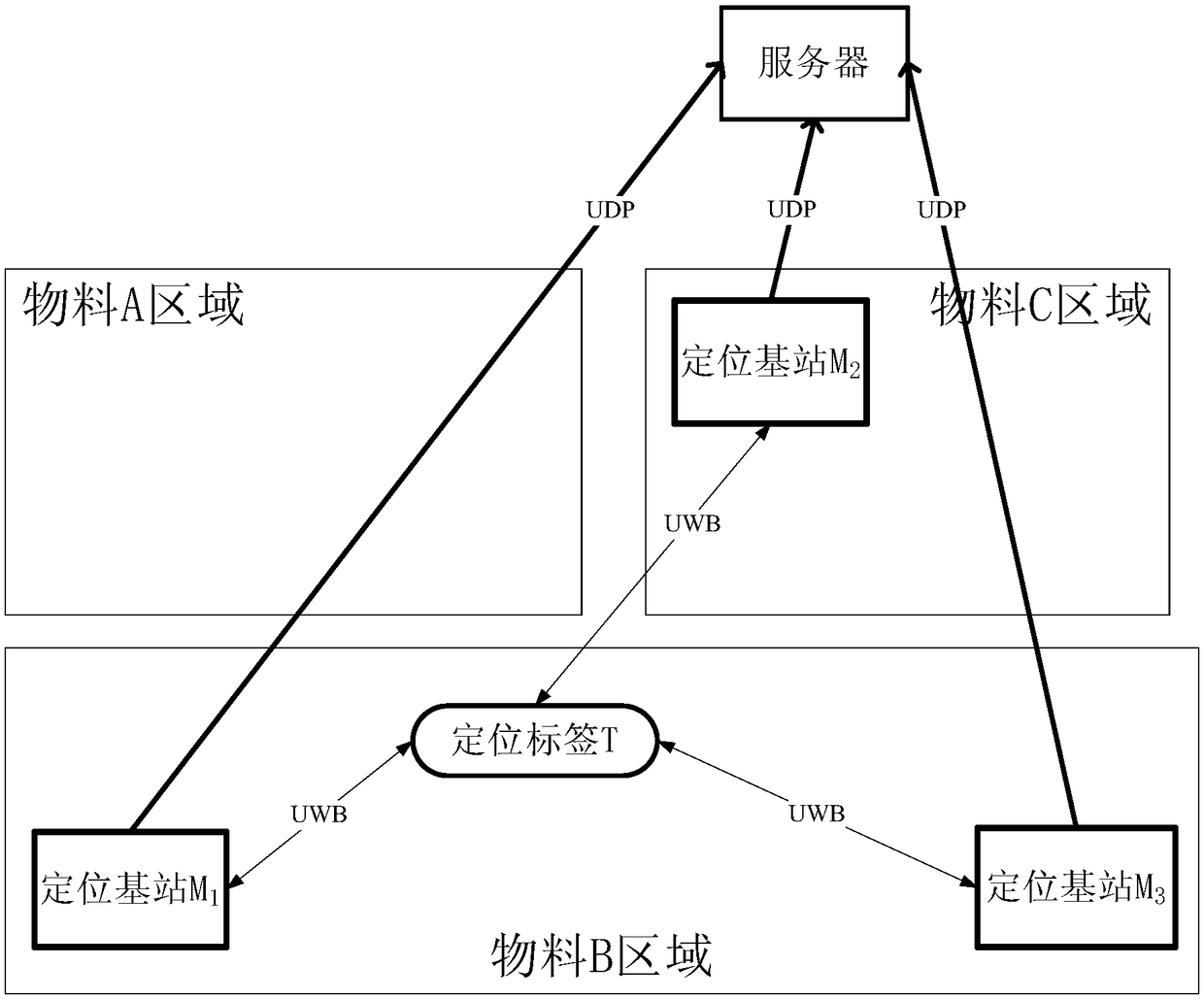

[0027] figure 1 The forklift positioning system for industrial indoor scenes according to the present invention consists of three parts: a positioning base station, a positioning tag, and a shovel material control system composed of a server.

[0028] 1. Locate the base station device

[0029] (1) The hardware for positioning base station M mainly includes the following parts:

[0030] Base station backplane: the bridging substrate where each functional module communicates with each other and controls each other

[0031] Power supply part: provide 12V, 5V, 3.3V required by the whole base station system. The input can be DC 12-48V, or it can be POE power supply in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com