Aluminum-coated carbon fiber conductor strain clamp

A technology of aluminum-coated carbon fiber and tension-resistant clamps, applied in the field of hardware, can solve problems such as complex processing procedures, potential safety hazards of transmission lines, uneven force, etc., to avoid cutting-edge discharge phenomena, great practical and promotional value, and processing and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

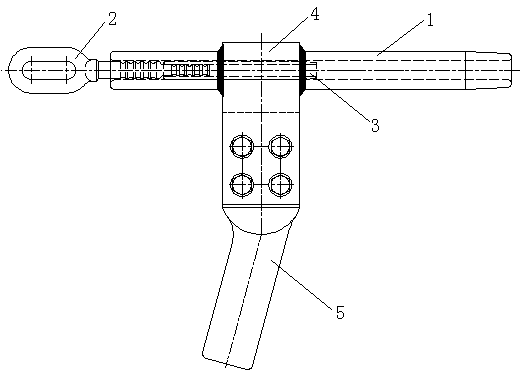

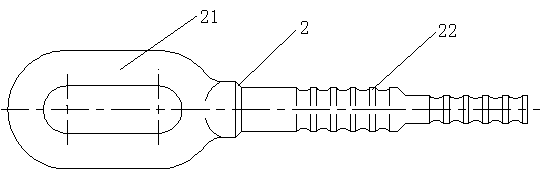

[0016] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , an aluminum-clad carbon fiber wire tension clamp of the present invention is composed of a clamp body 1, a steel anchor 2, a crimping tube 3, a drain plate 4, and a drain clamp 5, and the clamp body 1 is a hollow tubular structure , the inner diameter of the tube matches the outer diameter of the aluminum-coated carbon fiber conductor; one end of the clamp body 1 is crimped with a steel anchor 2, and the other end is crimped with an aluminum-coated carbon fiber conductor; the clamp body 1 is crimped with the aluminum-coated carbon fiber conductor The outside of the connection end is a tapered structure; the two ends of the clamp body 1 are arc-shaped surfaces; the drain plate 4 is provided on the clamp body 1; one end of the drain clamp 5 is connected to the drain plate 4 through a bolt, and the other end It is crimped with the jumper; one end of the steel anchor 2 is a pull ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com