Preparation method of aluminum clad steel pre-stranded wire

A technology of pre-twisted wire and aluminum-clad steel, applied in the field of pre-twisted wire, can solve problems such as hidden danger and surface corrosion of steel wire, and achieve the effect of improving capacity, convenient use, and eliminating the problem of end surface corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

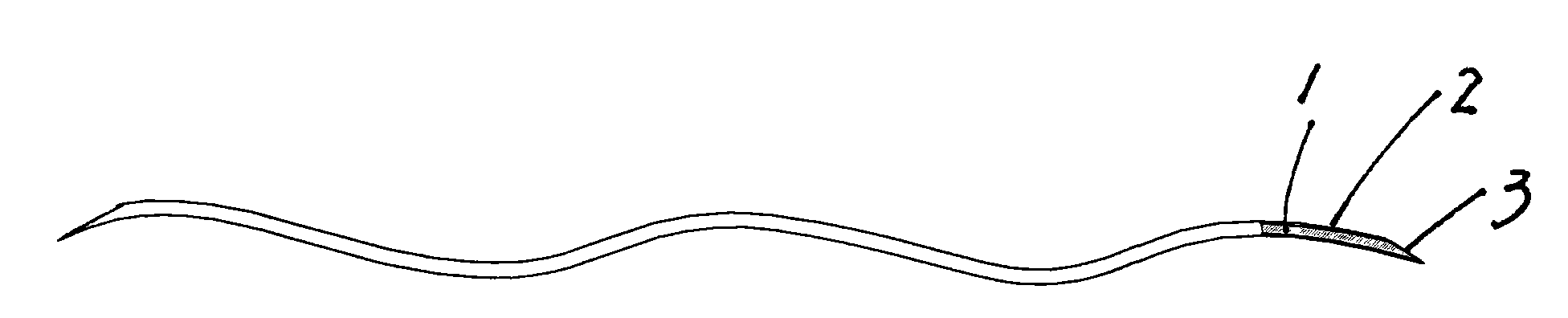

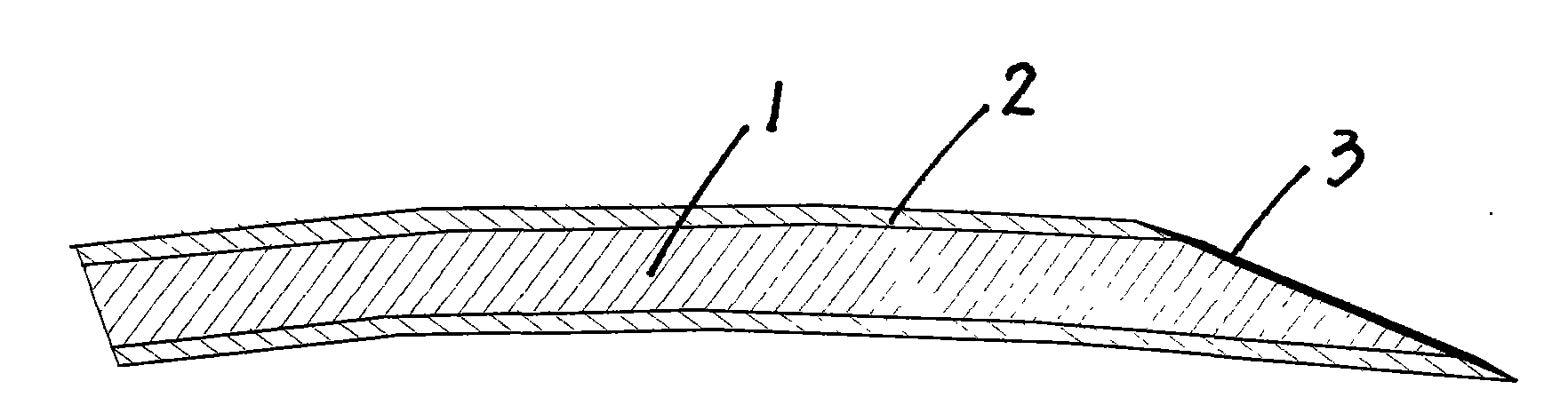

[0024] Refer to attached figure 1 , attached figure 2 , a kind of aluminum-clad steel pre-twisted wire of the present invention, it is made up of inner core steel wire 1, aluminum cladding layer 2, end face treatment layer 3, aluminum cladding layer 2 wraps the periphery of inner core steel wire 1, inner core Both ends of the steel wire 1 and the aluminum cladding layer 2, and the end of the inner core steel wire 1 are also coated with an end surface treatment layer 3. The cross-sectional shape of the two ends of the inner core steel wire 1 and the aluminum cladding layer 2 in this embodiment is Duckbill type; the end surface of the inner core steel wire 1 is also coated with an end surface treatment layer 3, and the end surface treatment layer 3 is a hot-dip galvanized surface.

[0025] A method for preparing the above-mentioned aluminum-clad steel pre-twisted wire, comprising the following steps:

[0026] ①The length of the pre-twisted wire is fixed;

[0027] ② Cut the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com