Panty-hose production method and device

A production method and technology for pantyhose, which are applied to the cutting of pantyhose, socks, textile materials, etc., can solve the problems of no production method, slow production speed, and inability to mass-produce pantyhose, so as to achieve a delicate and smooth hand feeling. , The effect of good product performance and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

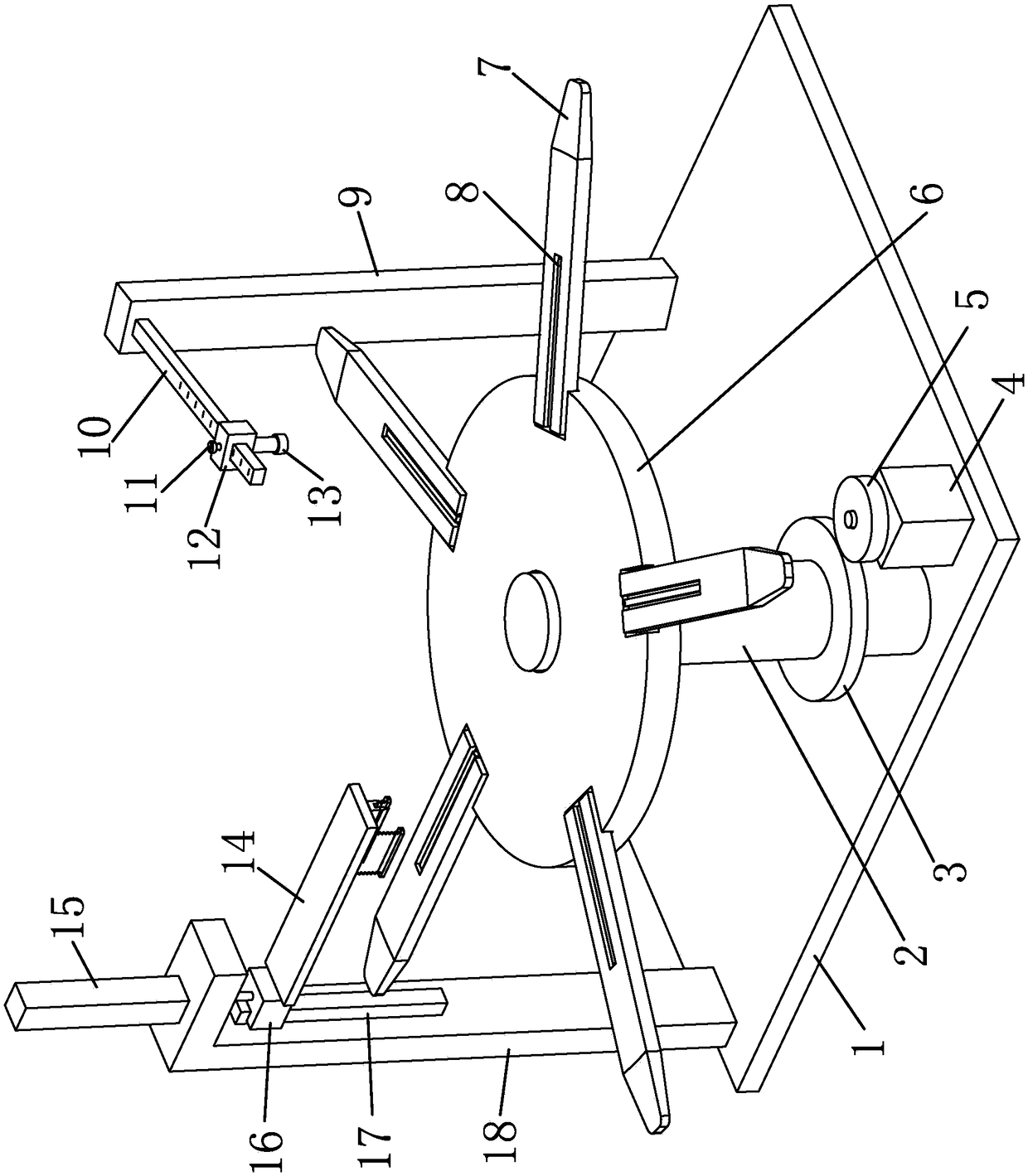

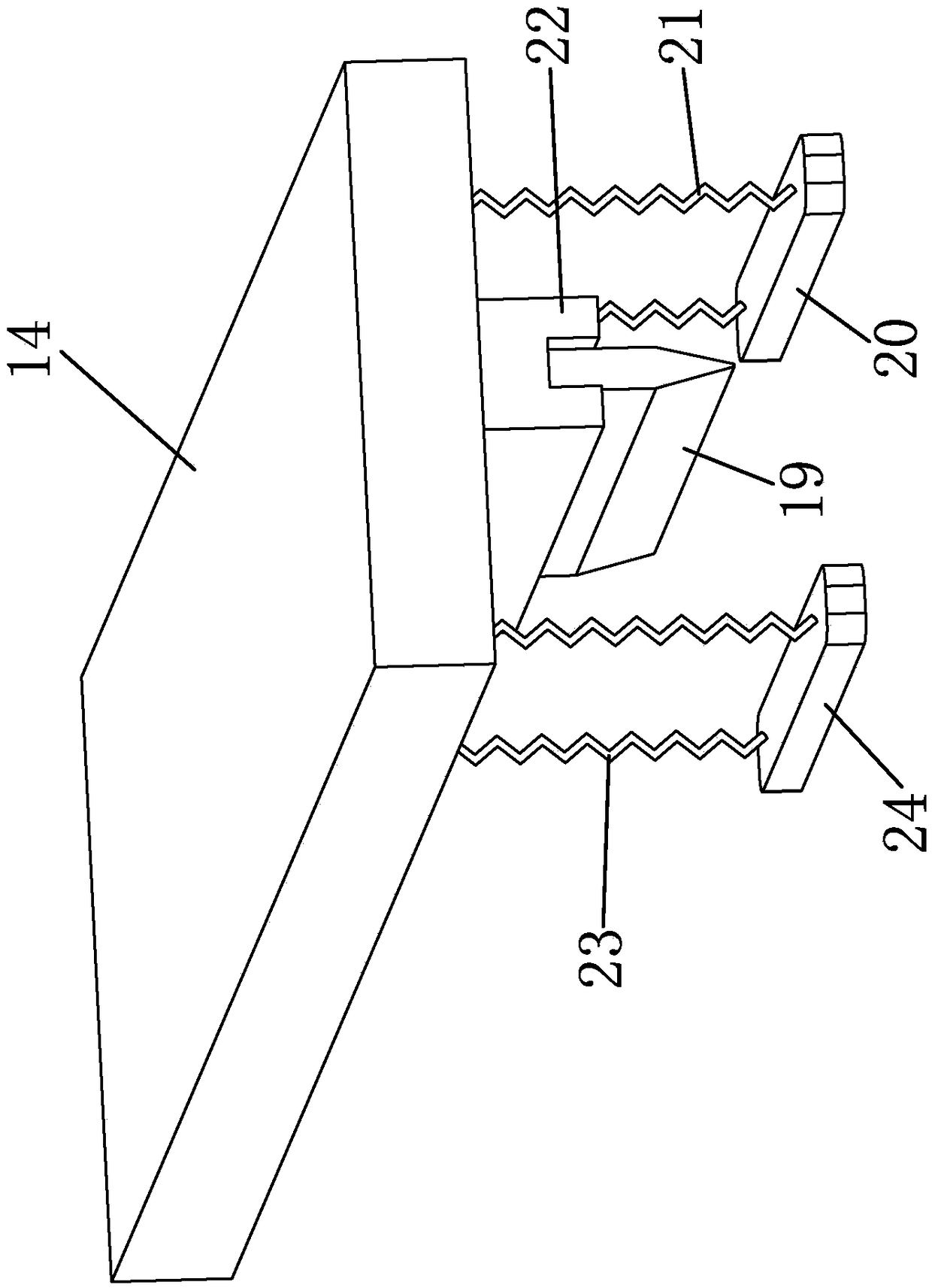

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

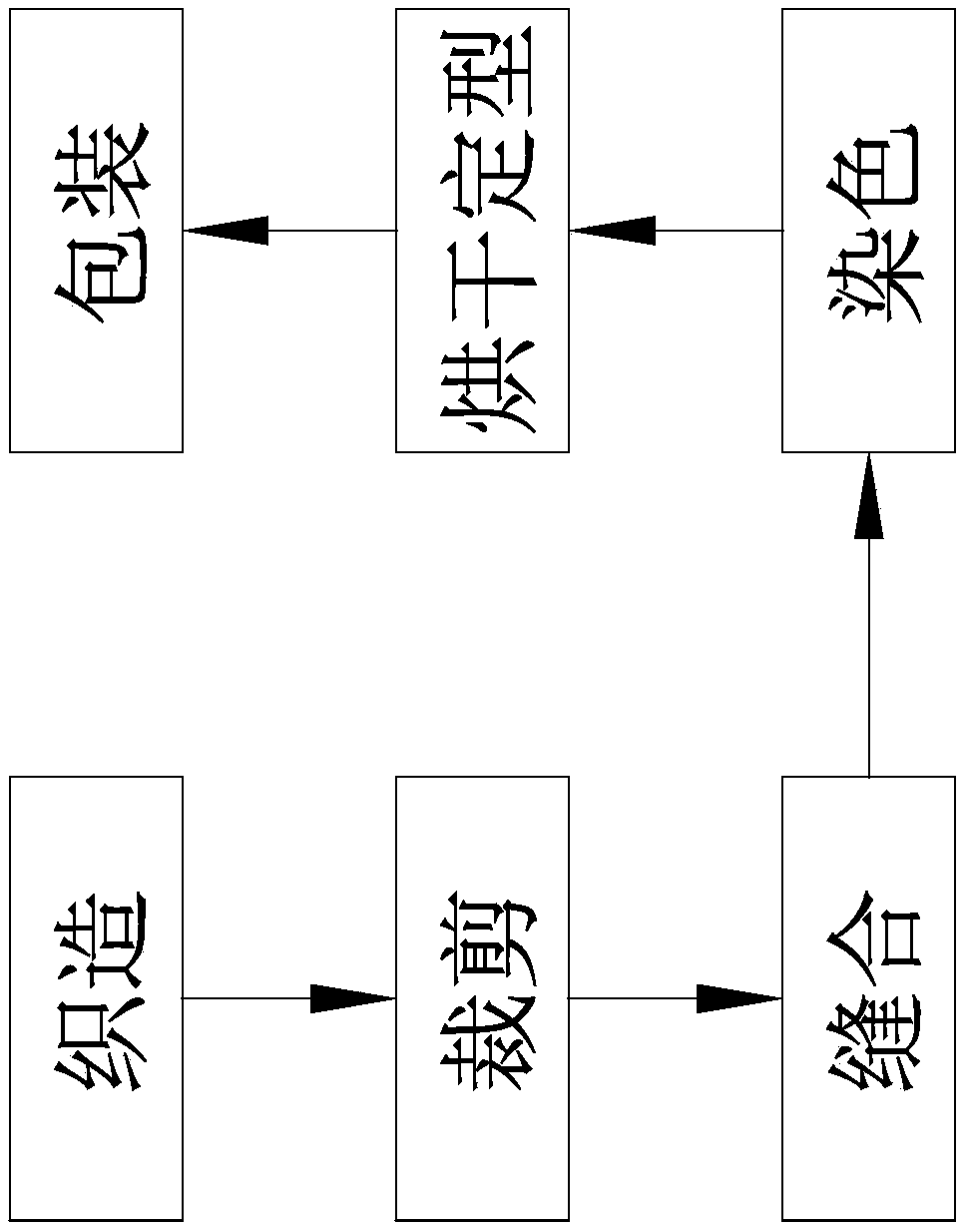

[0038] Such as figure 1 with Figure 4 Shown, the production method of this pantyhose, pantyhose comprises sock tube 25, crotch portion 26 and waist portion 27, comprises following concrete steps:

[0039] a, weaving: knit stocking tube 25 and crotch portion 26 by the stockings machine, weave the waist 27 by the seamless underwear machine; in the present embodiment, what the stockings machine and the seamless underwear machine all adopt is existing equipment;

[0040] b. Cutting: opening the sock tube 25 through efficient cutting equipment to form a joint;

[0041] c. Stitching: stitching with a sewing device, first stitching the sock tube 25 and the crotch portion 26, and then sewing the waist 27 with the sock tube 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com