Printing ink production technology

A production process and ink technology, applied in the direction of mixers, mixers with rotating stirring devices, shaking/oscillating/vibrating mixers, etc., can solve the problems of low dispersion, achieve easy acquisition, reduce grinding time, and reduce process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

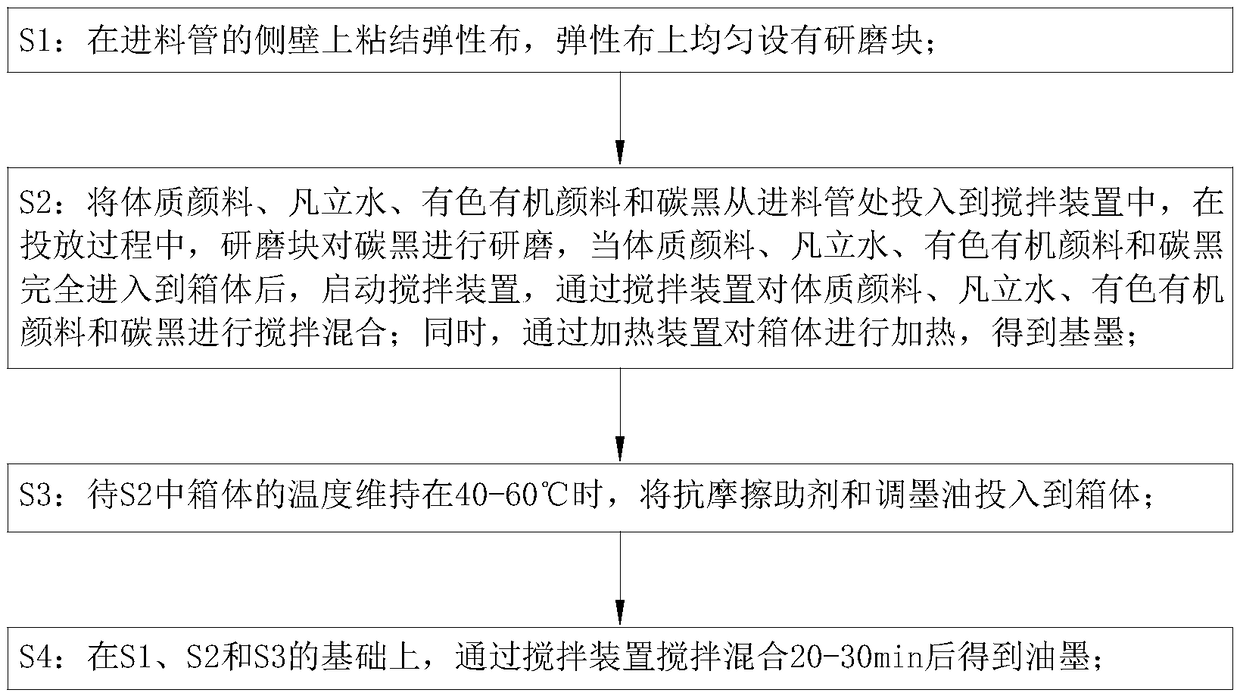

Method used

Image

Examples

Embodiment approach

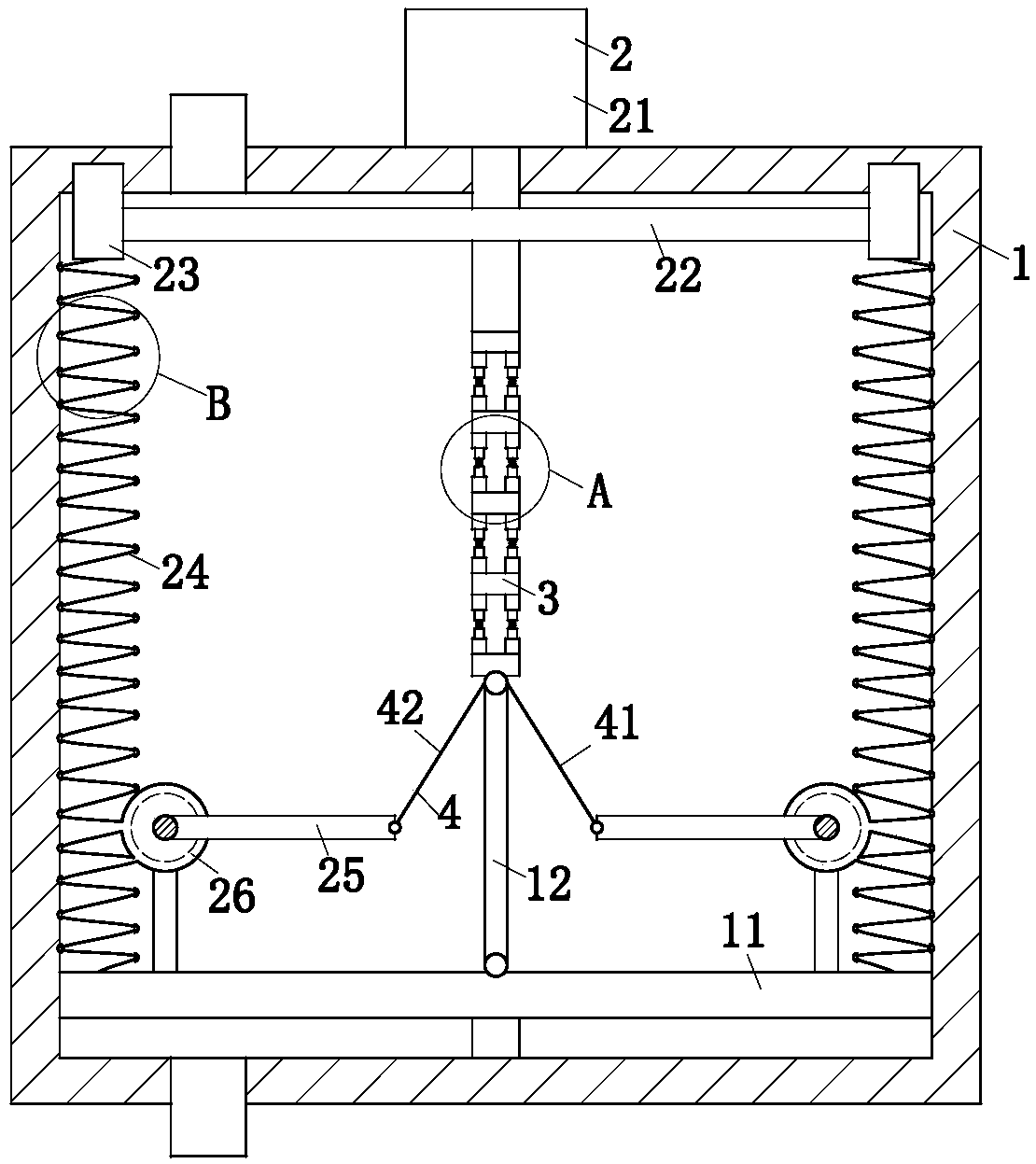

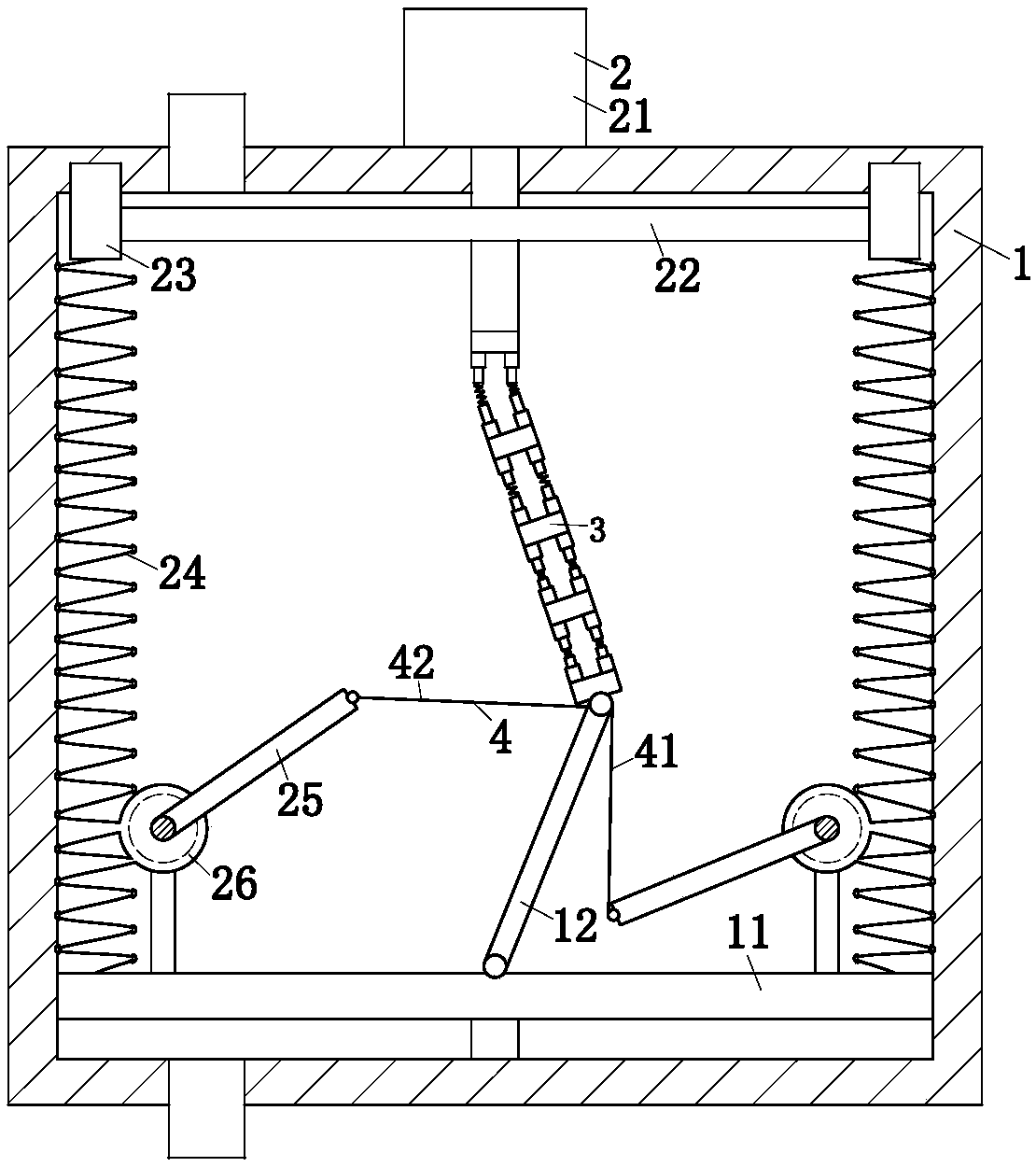

[0041] As an embodiment of the present invention, the stirring unit 3 includes a fixed block 31, a No. 1 cylinder 32 and a No. 2 spring 33; The center line of the center line is arranged symmetrically, two adjacent No. 1 cylinders 32 are connected by No. 2 springs 33 in the vertical direction, and No. 1 cylinders 32 are fixedly connected on the fixed block 31. Through the fixed block 31, No. 1 cylinder 32 and No. 2 The mutual cooperation between the springs 33 increases the stirring effect of the ink. The present invention is set to fixed block 31, No. 1 cylinder 32 and No. 2 spring 33 by stirring unit 3; By the mutual cooperation between fixed block 31, No. 1 cylinder 32 and No. The adjacent No. 1 cylinders 32 are connected by the No. 2 spring 33, which improves the flexibility between the No. 1 cylinder 32 and the fixed block 31, and ensures that the stirring unit 3 can swing the fixed block 31 and the No. 1 cylinder 32 under the rotation of the motor 21. , which increases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com